The stability and reliability of the erected roofs depends on the quality of its supporting structure, which is based on truss and truss trusses. This structure must withstand significant loads, including the weight of the roofing "pie", the mass of snow accumulating over the winter and the effects of wind.

The stability and reliability of the erected roofs depends on the quality of its supporting structure, which is based on truss and truss trusses. This structure must withstand significant loads, including the weight of the roofing "pie", the mass of snow accumulating over the winter and the effects of wind.

- General information about roof trusses

- How to choose a farm scheme?

- Structural solutions for simple triangle trusses

- Supports for rafters

- Calculation of roof systems

- Where are truss trusses made?

- Reinforced concrete and steel roof trusses

- Installation of roof trusses during the construction of a pitched roof

- conclusions

General information about roof trusses

Under the definition of a truss truss in construction, we mean rigid structures that are used to construct pitched roofs.

The task of trusses is to transfer the load exerted on the roof to the walls of the building. This roof element is usually made of wood, but other options are possible.

To make wooden roof trusses, boards, timber or round timber are used.

To connect the individual elements of trusses from logs and timber, the cutting method is used, and if the parts are made of boards, then anchors such as nails, bolts and ring-toothed dowels.

When building houses of a large area (the span is more than 16 meters), modern builders use trusses with stretched racks made of metal.

Since when using stretched wood racks it is quite difficult to make a reliable connection of nodes, while when choosing metal racks this issue is easily solved.

In addition, wooden roof trusses require serious assembly labor, while this stage of work when using combined trusses (metal and wood) is much faster.

As a rule, in the construction of residential buildings, the option of constructing a roof with open trusses is not used. Usually, the structure is closed by ceilings. Then, as in industrial construction, the option with open farms is one of the most common.

How to choose a farm scheme?

The choice of the form in which the truss truss should be made is carried out taking into account the following points:

- roof slope;

- roofing material;

- Type of connection of individual truss elements;

- The presence or absence of ceilings.

For example, if it is planned to install a practically flat roof (the angle of inclination is not more than 12 degrees) coated with bituminous roll materials, then the most advantageous shape option is a rectangle or a trapezoid.

With more significant roof slopes and heavy coatings, it is necessary to choose triangular trusses.

The height of the farm is calculated by the formula:

- For a rectangle - 1/6 * L;

- For a triangle - 1/5 * L,

where the letter L denotes the length of the truss span.

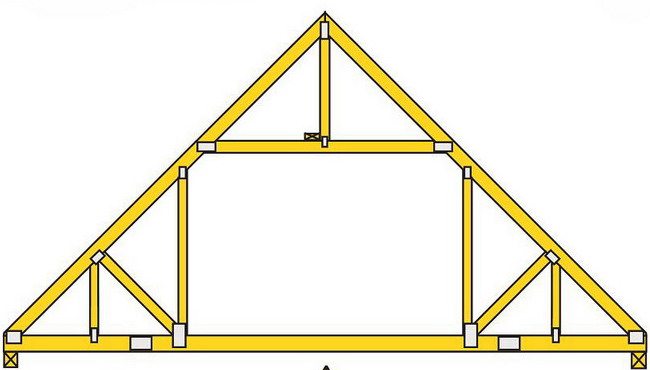

The most common option in private construction is a triangular truss truss. In combination with sloping rafters, this form allows you to create both single-pitched and double-pitched roofs with different angles of inclination.

During the construction of cottages with gable roofs, also, farms with hanging rafters are used. The choice of the shape of the rafters depends on how the trusses are attached to the walls of the house.

To achieve the necessary stability of the trusses, additional ligaments are installed for the upper (compressed) and lower belts. Bundles are made from boards and placed in the plane of the middle rack of the truss.

Structural solutions for simple triangle trusses

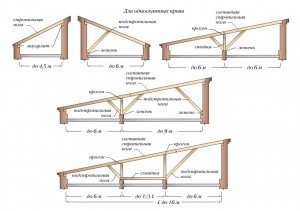

The simplest design is used for houses that do not have an internal load-bearing wall with a span of up to 6 meters. In this case, the roof truss is only supported by the outer walls of the building.

Its design is very simple, it consists of two rafter legs, puffs and two struts. If the width of the spans is more than 6 meters, then the installation of additional struts and a central support element is required.

Puffs installed on trusses, as a rule, make it difficult to pass through the attic space. To eliminate this drawback, the support for the ends of the rafter legs is planned directly on the walls, and the puff is placed approximately at the middle of the leg height.

This type of tightening is called a bolt.

This design allows you to create a comfortable attic space, but due to the bending of the rafter leg in the place where the crossbar is attached, a so-called spread occurs in the farm, which is transferred to the walls.

Therefore, these trusses with a crossbar can only be used with sufficiently stable walls that are firmly connected with the help of attic floor beams.

Supports for rafters

As a support for construction trusses, as a rule, not the walls of the house themselves are used, but a specially installed beam (Mauerlat).

The only exceptions are log houses, during their construction the supporting beam is not used, its functions are performed by the upper crown of the log house.

But if the house is built of brick or reinforced concrete, then the truss truss is a necessary element of the roof device. Their task is to evenly distribute the load on the walls.

As a rule, truss trusses are very durable structures made of metal. Truss elements are connected by bolts or welding. In some cases, reinforced concrete structures are used.

Calculation of roof systems

To calculate the rafter systems, it is necessary to take into account all the loads that will be placed on them.

Loads can be divided into three groups:

- Permanent (this is the weight of the entire roofing pie);

- Temporary (weight of snow, wind load, weight of people who rise to repair the roof, etc.);

- Special (this type can include, for example, seismic load).

The calculation of the snow load is made taking into account the weather conditions of the region.

The formula is used to calculate:

S=Sg*μ

- Sg is the calculated value of the weight of the snow load per square meter of pavement. This indicator is conditional and is determined by the tables, depending on the region.

- And μ is a coefficient that depends on the angle of the roof.

When determining the wind load, indicators such as:

- normative value of wind load (depending on the region);

- building height;

- type of terrain (open spaces or urban development).

You can find the necessary tables and formulas for calculations in building codes. As a rule, these calculations are performed by designers during the development of the overall project of the house.

If you rely only on your own strength when drawing up a project, then there is a high risk of making a mistake, which will lead to the roofing system being unreliable.

Where are truss trusses made?

If earlier in private construction, the manufacture of roof trusses was carried out directly at construction sites, today their production has been established in the factory.

Truss production is carried out on mounting and pressing equipment. If wooden products are produced, they are pre-treated with protective compounds to prevent premature decay and insect damage.

Using modern technologies, it is possible to make truss and truss trusses for a roof of any shape.Moreover, both whole farms and their individual elements, which are assembled into a structure at a construction site, can be produced.

Reinforced concrete and steel roof trusses

In addition to wooden structures, steel roof trusses are often used in private construction. They are made in three types:

- triangular;

- With parallel belts;

- Polygonal;

If a soft roof is planned, then the last two types of trusses are suitable; for sheet roofing materials, it is worth choosing trusses in the form of a triangle.

In industrial conditions, steel truss trusses are made of unified sizes, designed for spans of 36, 30, 24 and 18 meters in length.

Truss belts and their lattices, most often, are made from corners, and individual elements are fastened together by welding. Rational is the design, the belts of which are made of tee wide-shelf beams.

Such structures are easy to manufacture, and less steel is used on them, while they retain high strength characteristics and are very reliable.

A steel truss truss differs from a truss truss by the presence of a parallel belt. They are produced in the same unified sizes as truss trusses.

In the construction of private houses, steel truss trusses made of a profile pipe are more often used. Such structures are lighter than trusses made from a corner, channel or brand.

This design can be assembled directly on the site where the construction takes place, using a welding machine.

For the manufacture of trusses, hot-rolled or bent profile pipes are used. Steel for their manufacture is used with a thickness of 1.5 to 5 mm, and the pipe profile can have a rectangular or square section.

In modern construction, reinforced concrete trusses are also used. These are durable lattice load-bearing structures that are used to span long spans.

Such farms are recommended to be installed on the roofs of one-story buildings that experience significant loads on the coatings.

In construction, reinforced concrete roof trusses are divided into:

- Diagonal and non-diagonal segment trusses used for pitched roofs;

- Farms for low-slope roofs;

- Farms bezraskosnye triangular shape.

Such farms are produced in accordance with the requirements of GOST 13015.0, farms are evaluated:

- In terms of concrete strength;

- On frost resistance of concrete;

- According to the average density of concrete;

- By steel grades used for reinforcement;

- By the thickness of the concrete layer around the reinforcement;

- According to the degree of protection against corrosion.

In private construction, reinforced concrete trusses are rarely used, although they are very durable and reliable. The disadvantages of these structures include a large weight and the associated installation difficulties.

Installation of roof trusses during the construction of a pitched roof

Since the process of installing roof trusses requires professional skills and knowledge, it is better to entrust this matter to specialists. We will consider the simplest installation option during construction. do-it-yourself pitched roof.

At the first stage, the value of the wall difference should be calculated. This is done according to the formula:

H = W * tg L,

In this case, the letter H denotes the required wall difference, the letter Ш denotes the distance between the supporting walls, and the symbol tg L denotes the tangent of the roof slope angle.

- Next, you should prepare a sufficient number of wooden rafters and treat them with antiseptic impregnations.

- The next step is the installation of the support beam - Mauerlat. The thickness of the beam must match the thickness of the wall, it must be firmly attached and well waterproofed. When installing the support beam, you need to ensure that its surface is strictly horizontal. After installing the Mauerlat, the installation sites for the rafter legs are marked on it and recesses are cut out for their installation.

- Rafter installation. Prepared trusses are laid so that they protrude 30 cm beyond the surface of the support beam. Reinforce with brackets and bolts.

- Installation of supports and installation of crates. Supports are a necessary element if the length of the rafter legs is more than 4.5 meters. On top of the installed rafters, lathing slats are stuffed.

conclusions

Roof trusses, as well as truss trusses, are the load-bearing elements of the roof. Therefore, their calculation, design and construction must be treated extremely responsibly.

These works should be carried out only by professionals - architects, design engineers and installation specialists.

You can take on the work yourself only in the simplest cases, for example, during the construction of the roof of a garage or other outbuildings.

Did the article help you?