Do not know how to make a light and rigid floor in building structures with a large span? In such cases, it is best to use flat metal roof trusses. I will tell you what a farm is and how you can make it yourself in a home workshop.

For the manufacture of farms, it is important to choose a quality one. This can be purchased wholesale and retail at the NOVOSVERDLOVSK METALLURGICAL COMPANY. There are 8 types of rolled metal from various types of metal to choose from. All products are manufactured in accordance with GOST, and the company also provides a quality guarantee.

What is a farm made of?

By definition, a truss is a building structure made of rigid rods that are interconnected at nodes and form a geometrically unchanging system. The only invariable geometric figure in the coordinate system is a triangle, so any truss structure consists of many interconnected triangles.

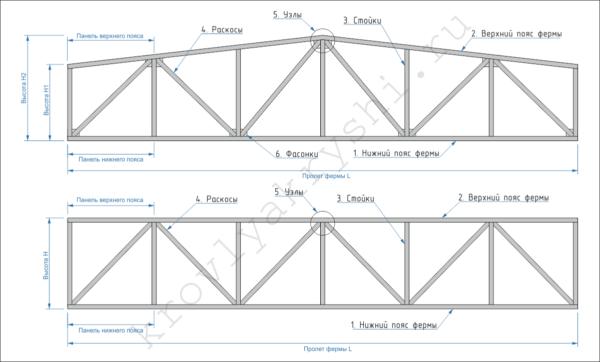

Technical parameters of farms are characterized by the following values:

- span length — distance between two nearest reference points;

- Bottom belt panel - the distance between two adjacent nodes on the lower longitudinal beam;

- Upper belt panel - the distance between the nearest two nodes on the upper longitudinal beam;

- Height - overall dimension of the truss with parallel vertical chords.

If the beam of the upper chord is not parallel to the beam of the lower chord, then two heights H1 and H2 are indicated. It is measured from the beam of the lower chord, to the lowest and highest point of the beam of the upper chord.

- Lower belt - a longitudinal horizontal beam that connects all the connecting nodes in the lower part of the truss structure;

- Upper belt - a longitudinal, inclined or radius beam connecting all connecting nodes in the upper part of the farm;

- Racks - vertical transverse ties that connect all nodes of the lower and upper chords. Perceive and distribute the main compression load throughout the farm;

- Braces - diagonal cross-links connecting all nodes of the upper and lower chords. They take tensile and compressive loads. The optimal angle of inclination of the braces is 45°;

- Knots - connection points of vertical posts and diagonal braces with horizontal beams of the lower and upper chords of the truss. In structural mechanics, they are conventionally accepted as an articulated joint;

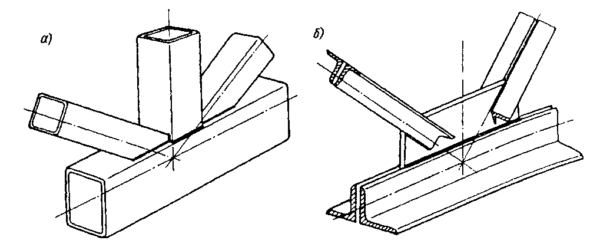

- Nodal connections. In the manufacture of truss structures, two methods are used to connect all elements in nodes:

- Welded connection with direct adjoining of all elements to each other;

- Bolted or riveted connection - all chords and cross-link lattices are connected to each other using a gusset made of thick sheet metal.

In the manufacture of a welded truss from a thin-walled steel pipe or angle, gussets are also sometimes used to weld the elements together.

Varieties of truss structures

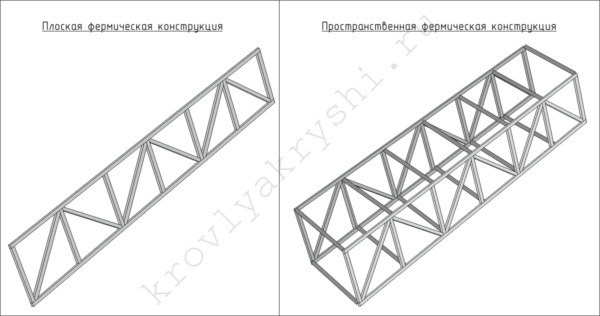

The main advantage of trusses over solid beams is a high bearing capacity with a low specific weight and low consumption of materials. According to their structure and the nature of the distribution of loads, truss structures are divided into two types:

- flat trusses - these are structures in which all the rods are located in the same plane:

- The direction of the applied load vector must coincide with the plane of the truss:

- To counteract lateral and shear loads, flat trusses must be fastened with additional longitudinal and diagonal braces.

- Spatial farms - are assembled from a set of rods that are oriented in all three planes:

- They are a little more difficult to manufacture, but at the same time they are able to withstand the simultaneous effects of vertical, horizontal and lateral loads;

- Due to this, spatial metal structures can be installed without connections with other structures, so they are often used for the manufacture of single beams, support poles, masts, etc.

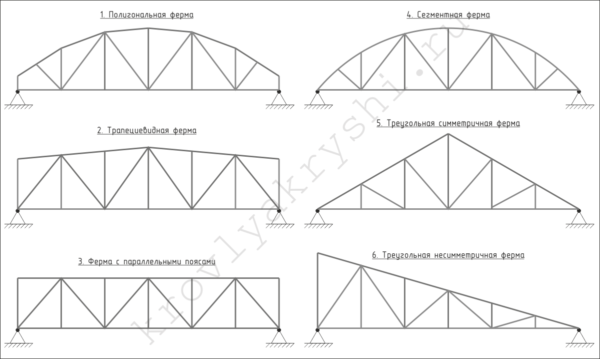

In private housing construction, flat farms are usually used, which, in turn, are also divided into several types:

- Polygon farms:

- For the manufacture of the lower belt, one solid beam is used, and the upper radius belt is assembled from several straight segments;

- Polygonal steel trusses are used for the construction of arched hangars or semicircular sheds and canopies with a large span.

- Trapezoidal trusses:

- The lower belt is made of one solid beam, and the upper one is made of two inclined ones;

- A trapezoidal metal truss is most often used in industrial construction with large spans, as it is able to withstand significant weight and wind loads. The main disadvantage is the high altitude.

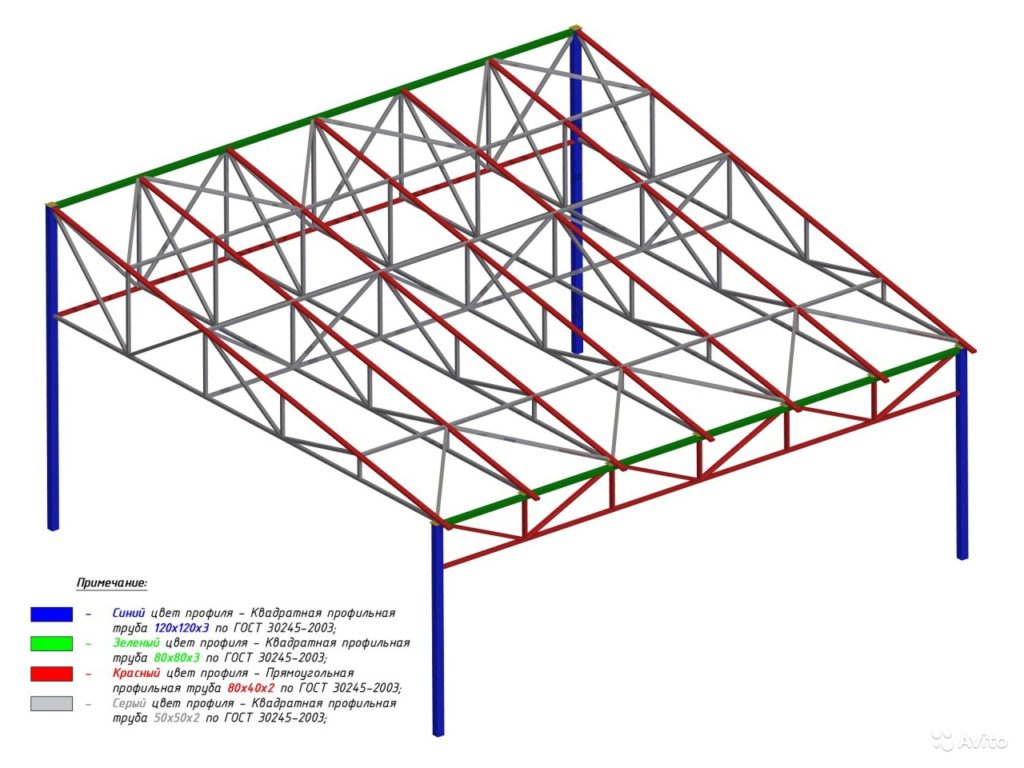

- Parallel or rectangular trusses:

- From the name it is clear that the upper and lower chords are made of two parallel beams, and the outline of the structure has a rectangular shape;

- This is the most common type of farm. They are easy to make with your own hands and they have practically no restrictions on use.

- Segment farms:

- They are made by analogy with a polygonal structure, only for the upper chord, not straight beams are used, but a solid segment of a circle;

- For the manufacture of segments, I advise using a rolling machine for steel pipes;

- Symmetrical triangular truss:

- They are made in the form of an isosceles triangle with vertical posts and diagonal ties;

- They are used in the construction of a gable roof, and the inclined beams of the upper belt are used as rafters.

- Asymmetric triangular trusses:

- They have a similar design, but are made in the form of a right triangle;

- They are used as load-bearing roof trusses for pitched roofs.

How to make a roof truss

Below is an instruction for the manufacture of a flat parallel truss. If you need a truss structure of a different shape, you can make it in the same way.

Stage 1: preparation of tools and materials

For the manufacture of trusses and spans, you will need a garage or a spacious home workshop, a set of locksmith tools and welding equipment:

Stage 2: making a flat truss

In most cases, building structures are assembled from several flat trusses of one or two identical sizes. Below I will give an example of the manufacture of one of them:

If you need to weld a lot of the same type of parts, I recommend that you pre-make a template on a sheet of thick cardboard, hardboard or plywood.

Conclusion

Now you know what metal trusses are used for and how they can be made in a garage or home workshop. I also advise you to watch the video in this article, and leave all your questions and wishes below in the comments.

Did the article help you?