A gable roof, often also called a gable roof, consists of two planes - slopes that have a certain slope. At the top, they converge together, this highest edge of the roof is called a ridge. In a section, such a structure is a triangle that rests on the walls of the building and closes at the top with a ridge, or parallel to the tongs, or rising above them. When building a gable roof with your own hands, you can vary its angle of inclination, as well as the height of the descent.

A gable roof, often also called a gable roof, consists of two planes - slopes that have a certain slope. At the top, they converge together, this highest edge of the roof is called a ridge. In a section, such a structure is a triangle that rests on the walls of the building and closes at the top with a ridge, or parallel to the tongs, or rising above them. When building a gable roof with your own hands, you can vary its angle of inclination, as well as the height of the descent.

About the slope of the roof

One of the most important parameters of a roof is its slope. It depends on how quickly precipitation is removed from the roof. If your area is rather dry, then you can make a slope of 25/45º. When there is a lot of rainfall in the region, the optimal roof pitch is 45°/60º.

Note! It is worth noting that the greater the angle of inclination of the structure, the higher its windage. Therefore, in areas in which strong winds are frequent, it is necessary to calculate the gable roof so that its slope does not cause too strong wind loads that can destroy it.

On the slope of such a roof as mansard roof, influences the choice of coverage. So, slate and tiles are used on slopes, the slope of which is not less than 22 °, otherwise there is a danger of precipitation penetrating into the under-roof space through the joints.

The total cost of the roof also depends on the slope. The higher it is, the more materials will have to be spent, as a result, the final result will be more expensive.

Structures of truss systems

The main elements of the truss truss are the rafters, the struts, the mauerlat and the crate itself. The upper sides of the rafter legs must be overlapped with overlays, the lower ends are fixed to the mauerlat or support bars constructed from logs processed in two edges.

The truss structure of a gable roof, depending on the shape and span, can be layered or hanging.

truss system gable mansard roof layered type is used in buildings with internal load-bearing walls that serve as supports for the structure.

The number of additional supports in this case may be different, depending on the width that the span has. If it is up to 10m, then one intermediate support is enough, if more, the number of supports must be increased.

Racks are mounted on the inner walls in increments of 4/6 m, girders or a ridge beam are fixed to them.

Such a gable roof device is most often used because of the ability to use lumber that has a short length and ease of installation.

Hanging roof trusses are used in buildings with large spans and in which there are no load-bearing internal walls. This stable geometric figure consists of an upper belt - a pair of rafter legs, and a lower belt - puffs, which are rigidly connected to each other into a truss.

A similar construction of a gable roof is such that the rafters lie with their ends on the outer walls, the support for them is the Mauerlat.

The use of such trusses simultaneously solves two problems: with the absence of internal supports, it is possible to equip a gable roof, as well as hang the attic floor structures from the lower belt of the truss system.

If the spans are more than 9m, then an additional lattice of racks, struts, and also crossbars is needed. It will increase the rigidity of the truss and will not allow long rafters to sag. The hanging truss system is assembled on the ground and mounted on the roof as a whole, ready-made.

The construction of the truss system and counter-lattices

The most common are gable roofs with layered trusses. First you need to lay the Mauerlat on the outer longitudinal walls.

The support beam, the section of which is 15 × 15 cm, is attached to the wall with anchors, waterproofing must be laid under it - strips of roofing material. Next, the rafters are placed.

Their upper sides are fixed to the ridge beam or overlapped with steel plates. The bottom is fastened with brackets to the Mauerlat and with twists - to the walls of the building.

To make the rafters more stable, struts are made between the racks and girders.

The size of the rafter legs, struts, battens, etc., determines the calculation of the roof of a gable roof.

The width of the rafter boards, as a rule, is 5 cm, the height is 15 cm, 18 or 20. To form an overhang that will protect the outer wall from getting wet, the rafters or puffs are taken out of its plane by at least 40 / 50 cm.

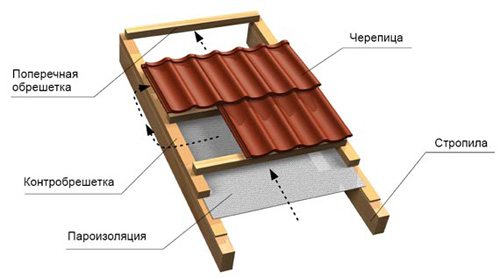

After the installation of the truss system, the arrangement of the roof pie begins with such a design as gable roof for your home. To do this, you need to assemble a counter-crate.

These are bars, the section of which is 5 × 5 or 6 × 6 cm, fixed along the rafter legs. The counter-batten plays an important role - it creates a ventilation gap between the insulation and waterproofing.

Roof waterproofing and insulation

Between the rafters, heat-insulating material is laid in several layers with offset seams. It is recommended that its total thickness be slightly less than the height of the boards.

It is advisable to use mineral wool as a heater, which has a low thermal conductivity and a density of at least 35 kg / m³.

From the inside of the heat-insulating material, a vapor barrier made of a dense polyethylene film is stretched and fixed. Next, the installation of a gable roof.

continues with laying on the outside of the insulation (on the counter-crate) a waterproofing vapor-permeable film - a diffusion membrane with a perforated structure. This material allows steam that has entered the insulation from the interior to the outside, but does not allow moisture to seep from the outside into the insulation.

Note! In addition, due to the height of the rafter legs and the arrangement of the counter-batten, a ventilation space is created on both sides of the insulation. Thus, moisture from the atmosphere or steam from the premises is blown out, and wooden roof structures do not suffer from them.

Assembly of the crate

When a gable roof is being constructed, the crate can be made from a beam with a section of 4 × 4, 5 × 5 cm or 6 × 6 cm. It is assembled perpendicular to the rafters and serves for flooring.

The crate takes on a lot of roofing material and redistributes the load on the rafters, which, in turn, transfer it to the load-bearing walls of the building. The first beam of the frame from the eaves will stare above all the others at the thickness of the coating.

Before you build a gable roof, you must choose the step of the crate, which depends on the type of coating material. For example, when installing metal tiles or profiled sheet metal, it depends on their chosen size.

There are materials that need solid flooring - these are all types of soft roofs, as well as flat slate. Under the soft bituminous tiles, on top of the flooring, a lining carpet is spread.

It serves to level the surface and protects it from moisture during the laying of roofing material.As a lining, fiberglass is most often used, which is impregnated with modified bitumen.

After the crate is assembled, you can start roofing work. We have posted on this page material on how to build a gable roof with our own hands: a video lesson will tell you about this in detail.

Did the article help you?