Currently, there are a large number of roofs. The most common is the gable mansard roof. It is this type of roof that is one of the most inexpensive and easy to install.

Currently, there are a large number of roofs. The most common is the gable mansard roof. It is this type of roof that is one of the most inexpensive and easy to install.

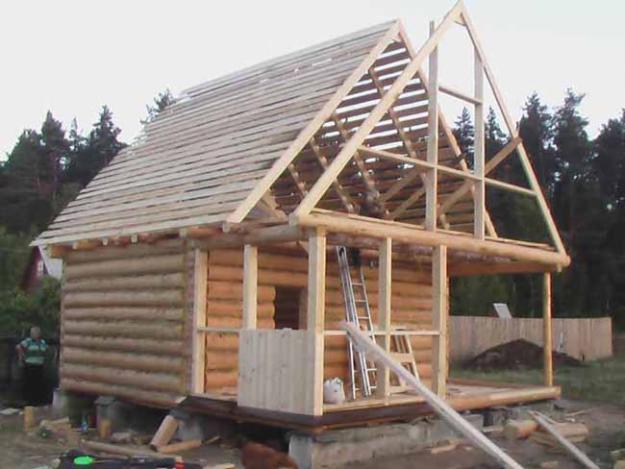

Such a roof consists of 2 slopes, rectangular in shape, which intersect at the ridge.

In principle, the design of such a roof can be almost any, which we will discuss further.

Advantages of gable roofs:

- Such roofs perform protective functions better than any others. In such a roof, snow is not collected, since it does not have valleys, water from precipitation can also flow freely from it.

- A gable roof is considered the classic option, which, moreover, is the simplest. Such a roof is used to create an exquisite architectural design.

- If a sufficient inclined angle is made, then the attic having such a roof has a normal height. You can also install window frames in it.

- With such a roof, you can safely operate with the size of the cornice overhangs and the shape of the gables.

- Materials for its construction are available and have a relatively low cost. A simple design does not require excessive financial investments, and it is even possible to build double pitched metal roof.

Roof structure

The question naturally arises: what is the design of a gable roof and how to build it?

This is what we will talk about below and describe one of the most common roofs, which is able to withstand the load created by snow, water runoff and at the same time is distinguished by reliability and convenience.

Construction

- It is necessary to build such a roof starting from the lower beams of the frames located under the rafters. Usually the size of these beams is 10 by 10 cm. They need to be laid on a layer made of waterproofing materials, such as roofing felt or roofing felt.

- After that, you need to fix racks made of timber on the beams. You need to do this on a plumb line. The size of such a beam is also 10 by 10 cm. They should be mounted in the same plane at a distance not exceeding 2 meters. They are fastened with staples or placed in a spike. In the future, they will serve as a frame for the construction of the walls of the second floor.

- After the posts are in place, they must be secured with temporary braces to maintain verticality. A bar having a section of 10 by 10 is laid on top of them and fixed.

- Outside, the racks need to be beaten with a slab, and in the middle they should be insulated and beaten with plywood.

- If the mansard gable roof is placed on a wooden floor, then the lower beam does not need to be laid. Racks are attached directly to the beams from the ceiling.After that, the maurlat is mounted, which is the lower beam, which rests against the rafter leg.

Maeurlat has several functions:

- Prevents the roof from tipping over by the wind.

- Distributes the load on the walls.

- Serves as a hook to the rafters.

Tip! You need to lay a roofing material under it to avoid getting wet coming from the wall.

After laying maeurlat proceed to the installation of rafters. For them, you need to choose straight boards that do not have knots, the thickness of which is from 40 to 50 cm, and the length is 1.5 meters.

They need to be installed at a distance of 100-120 mm. First you need to install the rafters located at the gables and only then the rest.

The final stage includes screwing the maurlat and rafters to the wall in several places. They also carry out the installation of fillies, which is no different from the installation of rafters. A hem should be pierced on the filly, which will prevent snow from entering the attic.

There is also a gable mansard roof of a special type - this is a roof with a bay window. The method of building such a roof began to be popular as early as the 17th century.

True, in our time it is no longer popular. A feature of such a roof is that the width of the overhang decreases due to the walls, while the overhang, as it were, turns outward.

There is a small break at the edges of the bay window, which improves the proportions of the roof. In principle, it looks like a fold that forms on clothes.

To make such a fold, you will need a corner rafter and two symmetrical valleys. The valleys converge at the ridge beam with their ends, and with their lower ends they find emphasis at the base of the last rafters.

The gap between the last rafters and the valley leg is filled with intermediate rafter legs. Such a rafter is not installed in a single place: between the corner and the valley rafters due to the fact that they are located at a short distance from each other. There is enough crate in this place.

At the final stage, the crate is nailed, the gable is closed and the roof is laid. Equally important is the installation of cornices, which are usually mounted at the ends of the beams.

In addition, semicircular decorative windows are also installed on the gables and, with the help of moisture-resistant plywood, the protruding ends of the beams are hemmed.

There is also a gable roof made of profiled sheet. Laying such material does not cause any difficulties. The only thing that is required is to follow the rules and not to forget about the features of working with this material.

To your attention! When installing such a roof, the most important thing is to properly lay the sheets. The correct laying is directly related to the angle of inclination.

In the event that the slope of the roof is not more than 14 degrees, then you need to make a horizontal overlap of at least 2 meters. If the slope is more than 14 degrees, but does not exceed 30 degrees, then 1.5-2 meters is enough for an overlap. With a slope exceeding 30 degrees, the overlap is made from a meter to one and a half.

Sometimes the slope can be less than 12 degrees, then it is necessary to use silicone sealant when installing a roof from corrugated board with your own hands without fail, which seals horizontal and vertical overlaps.

If it becomes necessary to cover the asbestos-cement sheets with corrugated board, then there is no need to redo the crate. Strengthening is not required for the existing structure, since corrugated sheets are light in weight and will not increase the load.

The sheet is fastened with self-tapping screws for the roof. They are made on a hat with a neoprene pad and a drill at the entrance.

Advice! This material must be fixed precisely in the lower wave part, unlike slate. This requires self-tapping screws with a diameter of 4.8 by 35 mm. To fix the skate, you need 50 cm self-tapping screws.

We should not forget about ventilation, the need for which depends on the following:

- What thickness will the waterproofing and heat-insulating layers have.

- What will be the temperature difference between the outer and inner sides of the structure.

- To what extent the roof provides tightness to the base of the roof.

In the event that ventilation is still needed, then in order to install it, you need to install special rails. They should be located on waterproofing in such a way that air enters unhindered.

Did the article help you?