Gable roofs are gaining more and more popularity in construction lately. This article will talk about what a gable roof is - construction and construction, as well as what materials and tools are used in its construction.

Gable roofs are gaining more and more popularity in construction lately. This article will talk about what a gable roof is - construction and construction, as well as what materials and tools are used in its construction.

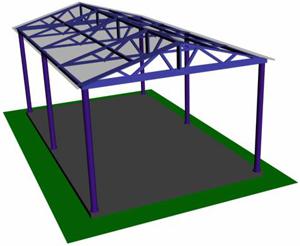

The gable roof device consists of two surfaces located at an angle to each other, based on load-bearing walls located at the same height. In the upper part of the slopes there is a ridge, and on the sides there are pediments that pass into the wall.

A gable roof is quite often erected during the construction of buildings such as cottages, summer cottages, country houses and other buildings with a small number of floors.

Their equipment and coating with roofing materials is a fairly simple procedure that you can do yourself.

The length and width of the slopes of such a roof can be very different, it depends solely on the project on which the house is being built. In the same way, the angles of inclination of the roof and the length of the roof overhangs can be practically any.

A gable roof frame is very common, which is a complex structure due to the placement of an attic on it, since in this case the four planes that make up the roof are brought together.

This allows you to equip a spacious living or attic space under the roof, which requires additional tightness and reliability.

Installation of a gable roof consists of several stages:

- Installation of load-bearing beams;

- The erection of crates;

- Installation of the material from which the roof is made.

Wooden beams and nails are used as the main material for the installation of the rafter system. The rafters are the supporting system of the roof, and the rafter system is a frame fixed on the roofing, in which insulation is installed.

The correct calculation of the gable roof is very important precisely during the construction of the truss system, since both the appearance of the resulting roof and its reliability depend on the competent installation of the rafters, so in no case should you try to save on any materials or do the work in bad faith.

It is very important to choose the right rafters. They should be made of flat, rectangular wood that does not show any signs of cracking or rotting.The most suitable material is pine, which has high strength and resistance to external influences.

Important: under no circumstances should rafters be made of twisted wood, this can lead to uneven roofs.

Very often, a gable roof is made using a wooden beam, although with the development of building technologies it has become possible to make reliable roofs from a metal profile, which provides them with a long service life and greater protection from negative external influences.

Gable roof device

The construction of a gable roof is carried out in the manner described below. This will require an edged board measuring 50x150 mm and a wooden beam, the dimensions of which are 150x150 mm.

Since this type of roof consists of two intersecting planes installed on the rafter system, its construction begins after the construction of the walls of the house is completed.

The first stage of construction is the laying of timber along the outer boundaries of the walls, and the distance between it and the wall should be at least 400 mm for more reliable protection from wind and precipitation.

Next, the edged board is installed on translations along the house, on which a gable roof is being built with your own hands. This board will later be used as the base of the racks.

Its fastening to the ceilings is carried out with the help of nails, then the racks themselves are installed and their upper part is tied.

Next is the installation of the rafter system. The first step is the installation of gables, which are essentially a continuation of the wall, forming the apex of the triangle, which will be the resulting gable roof.

In the case of installing an attic, it is strapped with fixing the board with a rib from above.

Useful advice: in order for the rafters to fit most tightly to the translations, ensuring high reliability, the lower part of the board is sawn off, for which the board is laid 100 mm edge on the translation, pressing it tightly against the leg of the rafters, and in this place a line is marked, along which it is made sawing.

The result should be a beveled thrust bearing, which should fit snugly against the translation throughout its entire length. Next, the rafters are installed, they are marked with lines for cutting off excess and cuts “in half a tree”.

After carefully fixing the upper parts with the help of an overlay, the final installation of the rafters is carried out. Along the upper edge of the strapping, the elements of the rafter system are fixed using a crossbar.

When fastening, it is recommended to use metal overlays and nails that provide permanent fastening.

After the installation of the gables is completed, you should check that all the peaks are on the same level. To do this, pull the rope from the top of the gable and use the level to check.

In the same way, the installation of the middle rafters of the system occurs.After their installation, in order to avoid sagging, the rafter legs are reinforced with struts as follows: one end of the strut rests on the rack, the second end is fixed in a special groove in the middle part of the rafter leg, after which the rafter leg is pierced with 200 mm nails, the ends of which are bent outside.

The cornice is made by laying a special crate, in which outlets are provided above the gables, which are 300-400 millimeters.

The main stages of the construction of a gable roof

The procedure for laying the roof with the right approach is not particularly difficult. It consists of the following steps:

- To install transfers or floor beams, it is first necessary to decide whether the operation of the attic space is included in the calculation of the gable roof and whether the attic will be equipped. For an ordinary attic, you can use an edged wooden board measuring 150x150 millimeters, but if you plan to build an attic, then you should use a bar of the same size. To ensure the best strength of the building, the board or timber should only be laid on the walls.

- Floor beams should be laid with a release from the outer edge of 400 millimeters, which will provide reliable protection against rainwater and wind.

- The bases on which the racks will be installed during the arrangement of the attic are edged boards, the size of which is 50x150 mm, it is recommended to fasten them with roofing nails. In order for the gable roof to have sufficient reliability and stability, all distances should be carefully measured, without allowing the slightest error.

- Next, the rafter system is assembled and installed, starting with the installation of gables in the manner described above and sawing off the lower parts of the boards to give the rafter system additional stability and reliability.

After the construction of the gable roof structure is completed, it is covered with roofing materials, for example, it is quite possible to build a slate roof with your own hands.

It should be borne in mind that each material has a certain weight, so the roof should be designed so that it can withstand:

- Self weight of the structure;

- The weight of the laid roofing and auxiliary materials;

- Additional loads in the form of snow and rainwater.

Tight fastening of the top is ensured by sawing the excess parts of the rafter system and washing them down. After the installation of the truss system is completed, the rafters should also be reinforced with a strut, resting one end against the rack, and the other - fastened in the center of the leg of the rafter.

Important: when arranging a residential attic under the roof, reinforcement of the rafters is mandatory, providing additional security for the people living in it.

The final stage in the construction of a gable roof is its covering with the selected roofing material, such as corrugated board, flexible tiles, metal tiles, etc.

Benefits of building gable roofs

Gable roofs have become widespread due to a number of advantages, such as:

- A simple design allows you to build a roof, such as slate roof by yourselfwithout resorting to the help of qualified specialists;

- The materials used are quite low cost;

- Due to the rather large angle of inclination, the removal of water from the gable roof is quite effective;

- The absence of complex technological solutions and kinks make the construction of a gable roof an interesting and simple task.

It should also be noted that the gable roof offers a wide variety of architectural and design solutions, such as concave or convex surfaces of slopes, arches and many other original forms, allowing you to make your home unique and unrepeatable compared to other buildings.

Did the article help you?