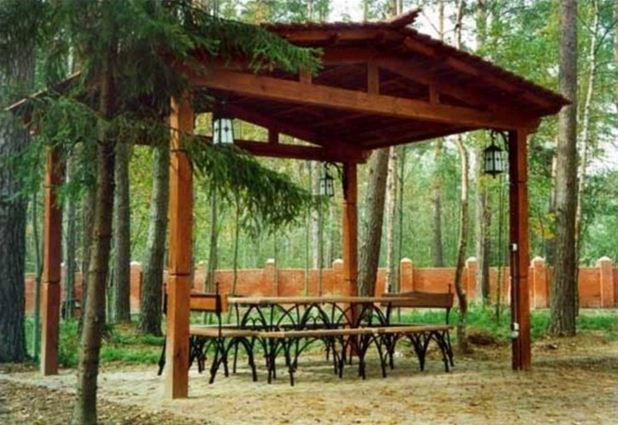

Canopies are structures without which almost no residential facility or building can do. They can be observed above windows, balconies, front doors, recreation areas, parking lots, etc. We want to talk about the features of these structures, as well as show how to build a summer canopy with your own hands.

Canopies and their features

Design

First you need to figure out what a canopy is like a structure, what elements it consists of and what are the design options for this product.

As a rule, all types of suspended structures have the following structural parts:

- Base frame. This part serves as a base, which bears all the loads perceived by the roof from wind, snow, rain, its own weight, falling objects, etc. It must confidently withstand any of the listed impacts, since otherwise the most valuable thing is endangered - human life and health;

- truss system. Depending on the type of roof, there can be single-pitched, double-pitched, hipped, hip, arched or any other type of truss system that performs the function of supporting the roofing material on which it is fixed. The parameters of this part of the structure depend on the size, climatic features of the area and the material used;

- Roofing. There are practically no restrictions here: traditional slate, galvanized steel, profiled sheet, plastic, ondulin and other types of coatings are used. As a rule, in order to better fit the canopy into the overall exterior, it is covered with the same material as the main building.

Important! As you can see, the design consists of three main parts, which allows us to attribute it to simple types of structures. This makes it possible to work on it independently without technical qualifications.

Let's analyze the indicated parts in more detail. The support frame can be made in a wide variety of ways: it can be a wall or several walls, it can be dug-in poles or a hinged structure that is attached to the vertical load-bearing wall of the house.

Depending on the type of support, one can distinguish attached canopies, free-standing models, hinged canopies and built-in varieties that are attached to walls and other parts of buildings in courtyards and rooms.

Important! For a summer vacation in the country, the option is best suited separately or attached to the front or side facade.

Go ahead. The truss system can also be a simple structure of sloping boards and battens supported by a tie-post or frame, or it can be very complex and elaborate.

Since we are talking about those models that can be built without the participation of professionals, we will not go into the details of complex systems within the framework of this article.

To build a simple shed system, it is not necessary to have special knowledge and skills; it is enough to carefully follow our guide at the end of the article.

Roofing is also not particularly difficult. It does not apply systems of insulation, vapor barrier, wind protection and other achievements of the modern industry of building materials. A simple crate made of board or plywood is covered with any coating, the main thing is that it does not leak.

Separately, it should be said about plastic roofing, such as polycarbonate, polyvinyl chloride, etc. These materials are not afraid of corrosion and moisture, do not require continuous or frequent lathing (sometimes they do not require lathing at all), and most importantly, their price is lower than that of other modern coatings.

Important! Already at this stage, we can draw an intermediate conclusion: we are not going to do the canopy of the awning with our own hands, so we choose a simpler option - a shed model with a flat roof. To show different ways of fastening, we will consider an option attached to the wall, where the far edge rests on poles.

Materials and tools

In this section, we decide what we make our construction from. There are several possible options here:

- The support frame and truss system can be welded from rolled steel. It will be reliable, durable, strong, but not beautiful. Moreover, not every summer resident has a welding machine and the skill to work with it;

- Only support poles and strapping can be made of metal, and the truss system can be made of wood. This will partially remove the issue of the beauty of the product, however, metal poles will still be discordant with the general atmosphere of outdoor recreation;

- Supports can be made in the form of brick or concrete pillars, however, this is a laborious and costly undertaking. The advantages here are obvious: strength, reliability, durability, beauty and comfort;

- Finally, the entire structure can be assembled from wooden parts and roofing material. This is the cheapest, but at the same time simple, beautiful, comfortable and fairly reliable option. With proper processing and high quality lumber, the structure can stand for more than a dozen years.

Important! Since we are going to attach our canopy to the house, we choose wood, since this is the material that is best suited for a country house.

So, we need:

- four pillars of timber 150x150 mm;

- upper harness from the same beam;

- rafters from a board 150x50 mm;

- supporting wall beam made of timber 150x150 mm.

In addition, you will need concrete, cast polycarbonate, bituminous mastic and a set of impregnations for wood.

From the tool you will need:

- jigsaw;

- wood saw;

- chisel for excavating recesses in a beam;

- hammer;

- screwdriver;

- shovel or motor drill;

- it is desirable to have a concrete mixer.

Consumables:

- nails;

- self-tapping screws with thermal washers;

- mounting angles or plates - it is also better to buy in advance.

Do not forget about control and measuring devices - levels, tape measures, rulers, plumb lines, etc.

Important! It is desirable to work in the warm season in dry calm weather. Wood does not like moisture, so before it is fully processed, it is better to avoid getting the structure or its individual parts into the rain.

Installation

So, let's proceed to the assembly and installation of the structure. For ease of perception, we have compiled a step-by-step instruction:

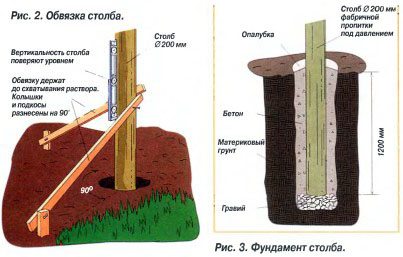

- We draw up a drawing or take a ready-made standard project and, according to it, mark out the territory near the facade of the house. We mark the installation sites of the pillars and dig holes there in increments of 1.5 meters, 70 cm deep, 35x35 cm in size;

- We cut out pieces of timber 150x150 mm 260 cm long, cover one edge with bituminous mastic to a height of 60 - 70 cm. We install them in pits, set them strictly vertically according to the level or plumb line, fix them with temporary puffs and concrete;

- From the same beam we make the upper strapping. To do this, we simply connect all four pillars in a line (we make small overhangs on the sides - 250 mm each) using a beam fastened into half a tree, nailed on top with nails or screwed with anchors and nuts. The attachment of the parts of the strapping to each other (the place of extension) must necessarily lie on one of the pillars;

- We fasten a piece of timber 150x150 mm 5 meters long to the wall opposite the pillars using anchors or dowels. You can hammer pieces of reinforcement with threaded threads into the wall, then drill holes in the beam, put it on the reinforcement and tighten it with nuts;

- We try on the rafter leg and determine the places and depth of cutting it into the wall beam and the piping of the pillars. We carry out the excavation of holes in the rafter boards;

- We mount the rafter boards on the edge with a step equal to the width of the sheet of polycarbonate you bought (the joints should fall on the boards). We fasten with the help of steel corners or special fasteners for rafters on wood screws;

- We sew the rafters with polycarbonate sheets. The material, if necessary, is easily cut with a construction knife, it is fastened with a gap between sheets of 1–2 mm to self-tapping screws with thermal washers. At the end, the gaps are closed with special plugs made of plastic or aluminum, or filled with an elastic sealant;

- We impregnate wood with antiseptic, antifungal and fire-fighting preparations, then paint or open the structure with varnish, oil-wax or other type of wood coating.

Important! Impregnation is best done before installation work, as it will be easier to process the ends and joints of parts.

Conclusion

The canopy is a simple design that is easy to reproduce on your site yourself. In order not to be mistaken, watch the video in this article.

Did the article help you?