It would seem that wood is not the most reliable material for roofing. However, it has been used for these purposes for a long time to the present day. Is it possible to lay such a roof yourself, how a wooden roof is arranged with your own hands and how long it will last - later in this article.

It would seem that wood is not the most reliable material for roofing. However, it has been used for these purposes for a long time to the present day. Is it possible to lay such a roof yourself, how a wooden roof is arranged with your own hands and how long it will last - later in this article.

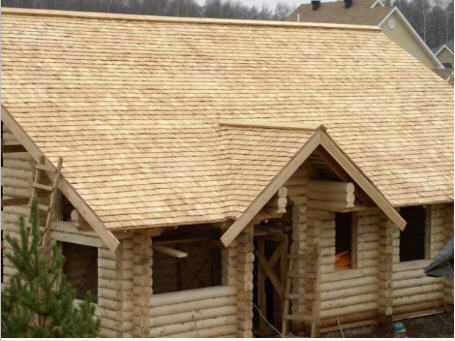

When the walls and roof are made of the same material, the view of the house is wonderful.

Wood is the oldest building material that man began to work with, so it is not surprising that the first roofs were also wooden. Thousands of years have passed, but the tree not only continues to be actively used in roofing, but has also regained its popularity in recent decades.

However, there have also been significant changes.If earlier wooden roofs were the cheapest and relatively simple to install, now it is one of the most expensive and time-consuming types of roofing to install.

Although, as before, a properly arranged flooring will last for decades, or even centuries, and will highlight the building with an original design.

Materials used

For roofing use:

- Shingle - small sawn boards with a longitudinal tenon-groove connection

- Shindel - "wooden tiles", small hand-cut planks of irregular shape

- Ploughshare - a kind of shingle, but the planks themselves are made in the form of a curved shoulder blade, or have a pyramidal shape, the lower edge is sometimes made curly

- Tes - edged board, sometimes - with a selection along the edge, made of coniferous wood

- Shingles - thin uncalibrated boards, chipped from a solid trunk of spruce, alder, aspen

- Wood chips - the same as shingles, but shorter

Important information! Of any type of lumber, only pitched roofs are arranged, while roof pitch should be within 18 - 90%. The greater the slope, the more material will be consumed, but the service life of such a roof will increase significantly.

Wood roof technology

Methods for constructing roofs from different materials have significant differences, and most of them allow for several possible options.

There are the following types of wooden roofs:

- Flat roof overlap

- Plank roof overlap in two layers

- Plank roof splayed

- shingled roof

- shingle roof

A shingle roof is the most difficult wooden roof to install - it is better not to mount it with your own hands without work experience.This material consists of boards 40-70 cm long and 10-15 cm wide, chopped by hand, rarely sawn.

Sawn shingle has a rough surface that absorbs moisture better, while chipped shingle retains the natural structure of the fibers.

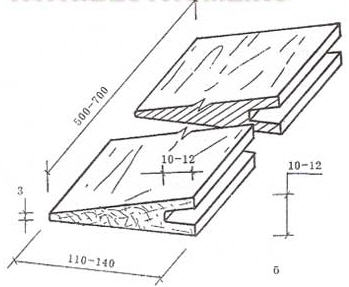

On one of the longitudinal sides, the plank is pressed into a wedge 3-5 mm thick, in the second, the thickness of which is 10-12 mm, a wedge-shaped groove is made 10-12 mm deep, the width of which at the beginning is -5 mm, and narrows to 3 mm towards the end.

Shingles are made from softwood, oak or aspen. The material is laid on a crate of poles or timber 40x40, 50x50 cm, or a continuous crate of boards.

If a crate is made of timber or poles, their axial pitch is 1/3 of the length of the shingle boards. In horizontal rows, all grooves should face the same direction; in a row, the narrow end of the shingle is inserted into the groove.

After installation, each shingle with the upper edge is nailed to the crate timber with one nail. The nail must enter the timber by at least 20 mm.

For different types of wood, different nails are used: for larch and cedar - copper, more suitable in color, for other species - ordinary galvanized.

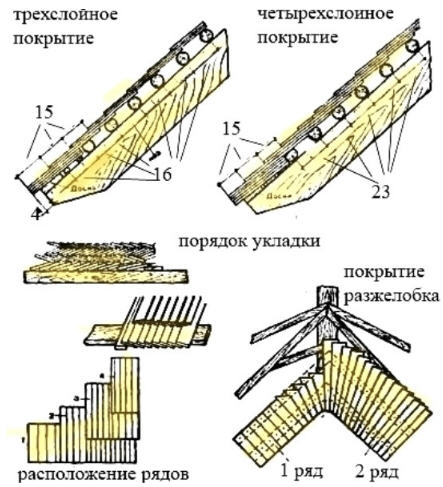

The shingle is laid in two layers - on arbors, gables of the roof, outbuildings, in three - on the roof of residential buildings, rarely, when increased reliability is needed - in four rows.

In this case, the next row covers the previous one by half - with two layers, on 2/3 - at three, and ¾ - at four.

The upper part of each plank, which is nailed to the crate, is also somewhat touched in order to reduce the overall thickness of the roof. The rows are stacked apart, that is, the edge of the board of the top row falls in the middle of the board of the bottom.

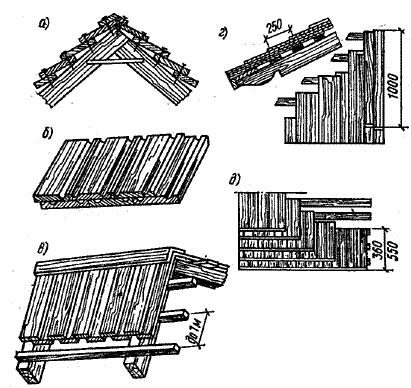

The grooves (concave joints of the roof) are fan-shaped, for which the boards used from the side of the narrow sidewall are planed down to the desired angle, giving the shingle a trapezoid shape.

Before laying, all planks are treated with an antiseptic, and if the owners are afraid of a fire, then with a flame retardant (fire extinguishing agent).

The shank and ploughshare are stacked in exactly the same way. The only difference is that the planks here are shorter - 20-40 cm, respectively, the crate bars are installed more often.

In addition, the sidewalls of the plates here do not have grooves and cones, but are stacked end-to-end with each other. However, not close, the distance between the planks in horizontal rows is about 3-5 mm, since when wet the material swells and the roof begins to warp.

With the same design, swelling at high humidity closes the cracks in the roof, and when the wood dries, the openings open again and provide good attic ventilation.

ADVICE! The best breed for any wooden roofing materials is larch.

She:

- It has a high density and resin content, as a result it is not subject to decay and damage by parasites.

- Has a long service life

- Very beautiful structure

- Relatively cheap

Roofing from shingles and chips

- rubbish

- crate

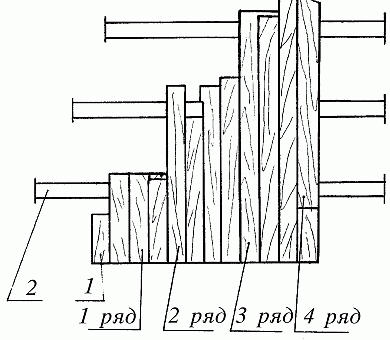

Roofing from shreds and chips is overlapped, both in horizontal and vertical rows. Most often, three- and four-layer coatings are made.

The shingles overlap along the length according to the same principle as the shingle: on a three-layer roof - by 2/3 of the length, on a 4-layer one - by ¾. Neighboring planks in a row overlap by 25-30 mm. The next layer is laid so that horizontally the upper bar with its middle covers the junction of the two lower ones.

In each beam of the crate, each shingle is fastened with a shingle nail 70x1.5. The skate is hemmed with a corner of the boards.

The technology for fastening a chipped roof is absolutely similar, but the length of the planks is shorter: for shingles it is 400-1000 mm, with a width of 90-130 mm and a thickness of 3-5 mm. Wood chips are slightly smaller: length 400-500 mm, width - 70-120 and thickness - an average of 3 mm.

Accordingly, for chips, a more frequent crate will be required: every 15 cm, while for shingles it can reach up to 30 cm. In general, in most cases, this type of roofing is arranged along a continuous crate.

Drape and wood chips are the lightest of wooden roofing materials, so under them you can arrange a crate of 40x40 mm timber.

plank roof

A tessel roof is perhaps the simplest and cheapest of all other wooden coverings. However, its durability is the smallest.

Important information! Previously, boards were hewn by splitting a single log along the length. At the same time, the fault went along the fibers of the wood, retaining all the properties of its array. Therefore, such roofs served for a hundred years or more. You should not expect such longevity from sawn boards, since its natural structure is broken. And it will be worse to resist the effects of weather conditions.

The plank roof is laid in a longitudinal (when the boards are laid parallel to the direction of the slope) or transverse (when the boards are laid parallel to the ridge) in a manner.

The second method is used only in temporary structures and is very simple.The boards are laid from the bottom up right along the logs, with each next row overlapping the previous one by 5 cm. Each board is attached to each log with one nail.

The longitudinal method has 3 options:

- In two layers end-to-end - the boards are laid with an offset of the upper layer relative to the lower one by half the boards, the distance between the boards in a row is about 0.5 cm for drying

- Razbezhke along the slope - the boards of the bottom row are stacked with a gap of 50 mm from each other, and the top row overlaps them with a call to each of the neighboring boards by the same 50 mm

- With the cover of the bottom layer with a flashing - the bottom row is laid solid, and the joints are overlapped with boards of a smaller width, also with an overlap of 50 mm boards of the bottom row

In any case, the boards of the upper row are nailed to the crate with nails, 2 nails in each bar. Lathing pitch - 600-800 mm. The thickness of the boards is 19-25 mm, the timber is 60x60 mm.

The numbers in the figure indicate:

- Top rows of boards

- Bottom rows of boards

- gutter

- skating board

- Lathing bars

- Eaves

The figure also shows a section of the board, which shows the grooves for water drainage, which are made in advance.

ADVICE! As a rule, hydro and vapor barriers are not laid under a wooden roof: wood does not form condensate inside the attic due to low thermal conductivity, but interfering with the free breathing of the material can lead to its accelerated damage.

Over the centuries, mankind has improved its skills in the manufacture of roofs, and wooden roofs are still in service, despite the advent of modern materials.

They are especially popular when covering wooden houses, because they not only give the building a holistic look, but also breathe in time with it.Although the installation of such a roof is not easy and expensive, but it is worth it.

Did the article help you?