For a wooden house, roof construction is a matter that equally combines aesthetics and practicality. The choice of options compared to buildings made of other materials is somewhat more limited here. Everyone saw the arrangement of the roof of wooden houses in pictures. How it is carried out in practice - later in the article.

For a wooden house, roof construction is a matter that equally combines aesthetics and practicality. The choice of options compared to buildings made of other materials is somewhat more limited here. Everyone saw the arrangement of the roof of wooden houses in pictures. How it is carried out in practice - later in the article.

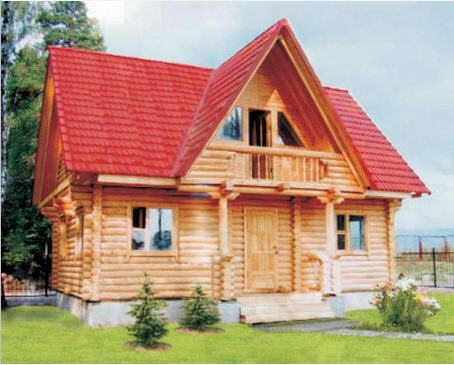

The roof should be in harmony with a wooden house, like with no other.

A wooden house is good in many respects: it is the most environmentally friendly, built from natural materials, with proper processing of logs, it is durable, provides excellent thermal insulation, is easy to process and securely holds hinged structures.

However, wood is a living material, and therefore has certain disadvantages: it cannot be guaranteed to rely on it in terms of geometry.

In other words, it is subject to deformation under the influence of temperature changes, and. especially moisture. Therefore, when building from various lumber, there are certain nuances that must be taken into account.

They relate to the order of installation of woodwork (windows and doors), shutter speed for shrinkage, included in this list, of course, and the device of the roof of a wooden house.

Not every material is suitable for it, you need to choose the right moment for its installation, and during operation it requires more careful control than in a building made of natural or artificial stone.

Important information! Shrinkage coefficients of various lumber: raw log and timber - 10%, raw profiled timber - 3-5%, dried and glued timber - 2-3%. In wooden construction, all design marks are always given in two values - before shrinkage, and after it.

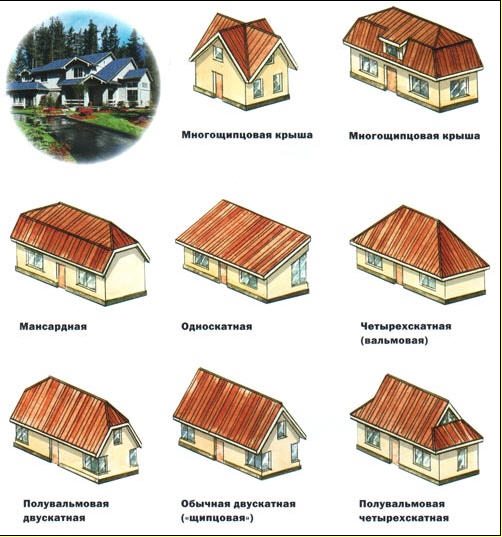

One rule is observed almost strictly by the types of roofs of wooden houses: they are extremely rarely flat and shed. This is not very practical for such structures, and it spoils the appearance pretty well.

Most often, owners choose different types of pitched roofs, and they, regardless of the roofing material, come in the following configurations:

- Multi-forceps

- Mansard

- Gable standard roof

- hip roof

- Do-it-yourself hipped roofs (a kind of hip with equal slopes of the same shape)

- Half hip gable

- Half-hip four-slope

The device of a wooden roof with slopes creates several additional amenities:

- The best thermal insulation of the floor

- Possibility of building an attic

- The use of cheaper roofing materials

- Self-dumping of the snow carpet in winter

- Better rainwater runoff

- The possibility of building long roof overhangs, which allows precipitation to be diverted outside the area where it can lead to wetting of the walls

Applied roofing materials

Most often, the construction of the roof of a wooden house uses the following types of coatings:

- Surfacing materials based on bituminous mastics (euro tiles, etc.)

- Roll deposited materials

- Ceramic tiles

- metal tile

- Slate

- Ondulin

The most preferred are light materials, such as metal tiles or ondulin - they make it possible to lighten the load-bearing structures, and significantly reduce the consumption of materials, speed up work.

Experts do not recommend euroslate and corrugated board: such a roof of a wooden house has an increased noise level in the rain and reduced waterproofing properties.

More exotic options can use the construction of the roof of a wooden house in a longitudinal overlap with a board, usually edged, or "historical" materials like reeds or straw.

However, the latest designs are created, as a rule, in various eco - or ethnic settlements, where it is important to create the spirit of the era or symbolize closeness to nature.

roof structure

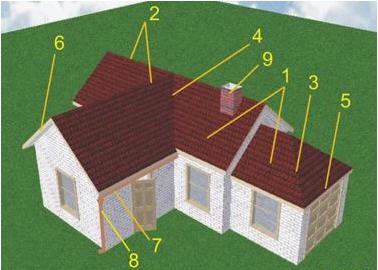

The main nodes of wooden roofs:

- Slopes - sloping roof surfaces, flat or curved

- Skates - upper longitudinal ribs formed by the junction of slopes

- Slope edge - a protruding corner at the intersection of the slopes

- Endova, or groove - a concave intersection of slopes

- Cornice overhang - part of the roof that protrudes beyond the perimeter of the walls of the building

- Gable overhang - the sloping edge of the roof over the wall

- Gutter

- downpipe

- Chimney pipe

Regardless of how to cover the roof of a wooden house, the roofing cake will always have approximately the same structure.

The crate for roofing material can be made of a bar (for metal materials and slate), boards (for them and tiles), be solid - for materials based on bituminous mastics.

Also, if it is not planned to equip an attic or other premises inside the attic, there may not be interior decoration. But the order of the layers is always the same.

In this case, it is important to observe the following rules, especially when the roof of a wooden house is arranged with your own hands:

- The layer of finishing material is located at a distance of at least 5 mm from the vapor barrier, so that in case of condensation, the lining does not suffer

- The vapor barrier is attached with sagging relative to the insulation. This leaves a ventilation gap. Also, the film in winter can be stretched from frost - sagging will not allow it to tear.

- Vapor permeability increases from the inside to the outside - the projects of the roofs of wooden houses are especially sensitive to this. That is, the ability of the waterproofing membrane to pass moisture (outside) must be higher than that of the internal vapor barrier. Otherwise, steam will accumulate inside the insulation, create condensation, and drastically reduce the level of thermal insulation.

- The under-roof space up to the vapor barrier layer must be well ventilated.To do this, special holes or gratings are arranged in the material of filing the overhangs, and a special gap is left under the ridge, closed from dirt and precipitation from outside

Important information! When installing the roof, do not use mounting foam! It can ruin insulating films, insulation, coating roofing materials.

Bearing structures

Before you build the roof of a wooden house, you should decide on its device. In all types of pitched roofs, the roof is attached to certain types of rafters.

The most common are layered and hanging schemes. Their main difference is that the layered ones have an intermediate support or supports at the points where load-bearing walls or partitions pass inside the building.

At the same time, the distance between the support and the outer wall should be no more than 6.5 m, the use of the second support allows you to increase each run (the distance between the middle support and the outer wall) up to 15 m. or logs.

Hanging rafters rest only on the walls, while exerting a bursting force on them. To avoid this, a puff is used, it prevents the rafter legs from moving apart. If the width of the house is large, an additional rack is installed, and the struts take on part of the load.

The simplest case is to order a finished house project from a company that sells glued or dried timber.

As a rule, there are many standard and universal solutions, and the wooden roof series, of course, also provides for the appropriate type.

When building from raw lumber, the matter is much more complicated, and it's all about shrinkage.For such cases, special "sliding" fastenings of the rafters to the Mauerlat are provided.

As the house shrinks, the rafters can move transversely relative to the beam, while maintaining the binding in the longitudinal direction.

Similarly, at the ridge, the rafters are also loosely tied. As a result, despite shrinkage, the roof remains in place and intact.

Due to the complexity of the design, such roofs of wooden houses must be designed and installed with particular care.

Therefore, without the appropriate skills, being a beginner, it is better not to take on their device. In general, the choice of roof structures, types of coatings and roofing materials for housing construction is huge.

It allows you to create a "headdress" for a home of any complexity. It remains to calculate your funds and decide on your desires.

Did the article help you?