At the end of the construction of the entire roof structure, it is time to file its overhangs, or, as it is called, just a file. Roof eaves filing is the final touch that contributes to giving the house completeness and, in particular, its appearance.

At the end of the construction of the entire roof structure, it is time to file its overhangs, or, as it is called, just a file. Roof eaves filing is the final touch that contributes to giving the house completeness and, in particular, its appearance.

Binder design gable roof provides for the installation of ventilation elements of the under-roof space, as well as the fastening of drains on it. Overhangs can be hemmed with a variety of materials and can vary significantly in design, for example, as roof lining with siding.

Features of the roofing device

For the first time, you should think about filing the roof overhangs when the installation of the rafters is completed and the sheathing is to be laid along the border of the roofing.

Design features are as follows:

- Before hemming the roof overhangs, the ends of the rafters must be sawn off strictly in one straight line. Moreover, it is necessary to observe the parallelism of such a line relative to the adjacent wall of the house.

- Most often, sheathing is done with boards. The appearance of the sheathing directly depends on the uniformity of the width on different sections of the wall. If the monotony of the width of the skin is not observed, the aesthetic appearance of the structure, with all the desire, cannot be achieved.

- The ends of the rafters must be sawn off vertically, while the end part should be sewn up by analogy with the entire filing.

- At the end of sawing the rafters along a single line, the first board of the crate is stuffed along it, which subsequently serves as a guideline for further work.

Advice! External insulation of the walls of the house must begin only after the filing of the roof overhangs has been completed. When installing insulation before installing the sheathing, in the process of work, you will have to tear off the boards to ensure high-quality and proper insulation.

The choice of material for sheathing overhangs

There are a number of different materials that can be used for sheathing.

However, each of them must have such properties that reliable protection of the eaves of the roof is provided - its insulation, protection from precipitation, ventilation of the space under the roof.

In addition to performing this kind of function, the material for filing must retain its original characteristics and properties for a long time.

So, the roof overhang can be hemmed with the following types of materials:

- Profiled sheeting, which is galvanized steel coated with a polymer material. Polymer coating provides not only additional protection for galvanized steel, but also provides the widest choice of colors. At the same time, galvanized steel provides the corrugated board with the necessary rigidity and resistance of its geometric dimensions to mechanical (wind pressure) and thermal (high temperatures) loads. Ventilation at the filing of corrugated board is carried out through a gap, which is created by the height of the wave. Panels can be made to the required width, which reduces installation time and financial costs for the filing itself.

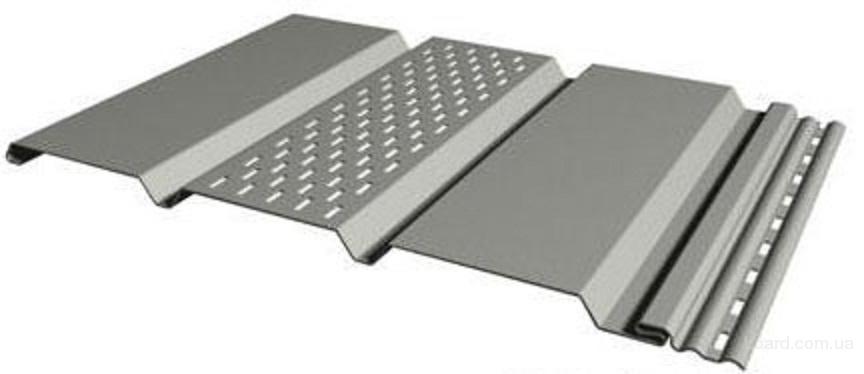

- Soffit - a plastic panel produced specifically for filing overhangs. Soffit is the most widely used material for filing and resembles siding, however, unlike siding, soffit has a greater thickness of plastic, and also has, as a rule, special perforation, which is designed to ventilate the space under the roof. In addition, UV stabilizers are added to the soffit plastic, which ensures better resistance of the material to direct sunlight. Soffit panels are cut along the length of the overhang and installed perpendicular to the wall, not lengthwise.

- Ordinary wooden clapboard. Due to the operation of the lining on the street under the influence of all kinds of weather vagaries, it must be chosen carefully with respect to the quality of the wood. The first thing you should pay attention to is the thickness of the products: they should not be thin. Next, you need to check the moisture content of the material: it should not be completely wet or too dry. The most acceptable option may be a lining that is stored for at least a month in the open air and has identical humidity compared to the environment.

- A planed and edged board with a thickness of 1.5-2 cm. Such a board should be stuffed with a gap of 1-1.5 cm. The advantage of the board is to ensure uniform air penetration around the entire perimeter of the roof and, accordingly, uniform and high-quality ventilation of the under-roof space.

- PVC lining, which is the most economical option. The lining is selected moisture resistant. When buying this material, one should not forget about the plastic corners with which the joints of the lining are attached, as well as U-shaped strips for sheathing the edges.

Features of the binder device and the binder frame

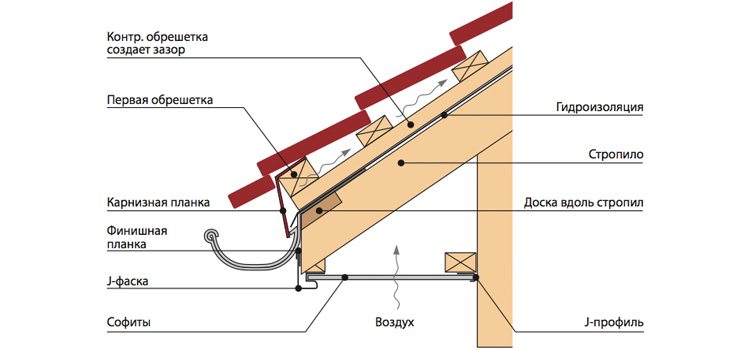

Upon completion of the installation of the roof structure, they proceed directly to the sheathing of the overhangs. The technology of filing roof overhangs involves two design options:

- Performing filing directly along the rafters. This type of filing is more suitable for roofs with a gentle slope, or when the task is to increase the height of the building. With this method of filing, the bottom of all rafters should be located in a single plane.If this condition is not met, the evenness of the plane is achieved with the help of additional boards stuffed onto the rafters with an overlap. Next, the first and last strips of the sheathing material are exposed and screwed, the threads are pulled to maintain the level, after which the remaining strips of material are attached. When converging at the corners of two roof slopes, boards are attached to the corner rafters on both sides.

Advice! The length of the roof overhang is usually assumed to be 600 mm.

- A more common option is to trim all rafters vertically and horizontally. A board is nailed to the bottom and to the end of the rafters, and a beam is attached to the wall 1 cm higher than the line of the parallel frontal board for possible moisture to drain. With an overhang width exceeding 450 mm, an additional board is installed in the middle. When converging at the corners of two roof slopes, the board is nailed from the corner of the house to the corner of the roof.

In both options, the installation of the roof overhang box on the gables is carried out in the same way: they stuff the board onto the crate along the gable along the wall, measure a distance from it equal to the width of the overhang, and then nail the board parallel to the gable wall.

Installation of corrugated sheeting

Finishing roof overhangs from this material is carried out as follows:

- The corrugated board is screwed with self-tapping screws to the frame along the wall and along the eaves.

- A frontal bar and an inner corner are mounted at the junction of the material and the wall. The inner corner is screwed to the corrugated board, the frontal bar - to the frontal board.

- The outer corner is fixed at the external joints of the corrugated board.

- Corrugated board is screwed along the gable along the outer edge of the overhang and along the wall.

- Next, attach the corners and the end plate.For ease of installation and ventilation, the width of the corrugated sheet is made 2 cm less than the width of the overhang.

To attach the soffit to the base, a J-shaped bar is used, which is fixed along the cornice and along the wall with self-tapping screws. Soffit sheets are inserted between the planks.

Soffit sheets are cut to a length that is equal to the distance between the J-shaped strips minus 6 mm (for thermal expansion), if the size of the roof overhang is more than 900 mm - 6 mm on both sides. The frontal board is closed with a frontal bar.

Did the article help you?