The construction of the roof frame is completed, the roofing material and insulation are laid, it's time to think about finishing the box (overhangs). To do this, you can use various materials, but we will tell you how the roof is made with siding.

Siding - facing the walls of buildings and performing two functions (Footnote 1): utilitarian (protecting the building from external influences, such as rain, wind, snow, sun) and aesthetic (decorating the facade of the house).

Hemming the roof eaves with siding affects the overall appearance of your facade, this is the final stage in the construction of the roof. Of course, it is not necessary to use siding, you can choose different materials.

What exactly? Let's consider.

Materials for filing the eaves:

- Vinyl siding is made from polyvinyl chloride.The material has a number of advantages: light weight, relative cheapness, easy installation, fireproof, non-corrosive and durable. This type of siding was specially designed to decorate facades, but oddly enough, it is not very suitable for filing a box. This is due to the fact that when performing this type of work, you will have to cut out the ventilation holes yourself, and this spoils the overall look.

- Galvanized metal siding is designed for cladding of hinged facades and walls of both old and new buildings. It has good technical characteristics, there is a wide choice of colors, it is relatively inexpensive and will last for many years. But he also has a drawback. Speaking specifically about the finish of the cornice, it is worth noting that moisture often collects in this place. Over time, the siding may begin to rust, and characteristic red spots will appear, especially noticeable on white. They will not add beauty to the building.

- Vinyl soffit has been specially designed for roof decking. Therefore, all the shortcomings of the previous materials were taken into account. There are three types: perforated, with central perforation and solid. Perforated provide air flow, which is so necessary for under-roof ventilation. Solid, mainly used for filing cornices. Vinyl spotlights are highly resistant to biological and mechanical damage, durable, installation does not require special knowledge or equipment.

- Aluminum soffit is made from a single sheet of aluminum with a decorative and protective coating. This material has a wide color gamut, good technical characteristics (better than vinyl spotlights), durable.Over time, spotlights do not deform, the color does not fade in the sun and does not change.

- Wooden lining used to be very often used for filing roof cornices. With the advent of new, modern materials, this material gradually fades into the background. This is due to the fact that wood quickly deteriorates from moisture, which means that it needs to be changed again, which is not profitable from an economic point of view.

Below is a table by the manufacturer of roofing materials (Footnote 2) Types of siding

| Vinyl siding - one of the most popular outdoor cladding materials. Docke Group offers several types of vinyl siding: classic Dutch, clapboard - imitating wood paneling, Blockhaus - wooden logs and vertical siding. | Docke Lux Acrylic siding - A type of vinyl siding.

Brighter colors are available due to special material properties. There are currently 6 "delightful" colors available - Pancho, Praline, Nougat, Cherry, Grillage and Iris. | Wooden siding WoodSlide - imitates the texture of natural wood.

Dock Group offers six different colors: walnut, rowan, apple, cedar, quince, maple. |

Which material to choose, everyone decides for himself. But the frame of the box does not depend on this. It is made according to certain rules. We propose to consider how.

Frame construction

Naturally, the design of the frame depends on the type of roof.

There are two options for any type of roof:

- Binder along the line of the rafters of a shed roof, For example. We collect the frame of the box so that the angle of inclination exactly coincides with the angle of the slope.To apply this option, it is necessary that the rafters (on the underside) have a flat surface. Usually for this it is enough to fasten a board 4 cm thick and 10 cm wide to the rafters. To begin with, we set the extreme boards in size, then we stretch the rope and fasten the rest along it. On pitched roofs, it will be necessary to attach two boards to the corner in the places where two slopes converge, on one side and the other.

- horizontal box. Such a box is mounted using two boards. One is attached to the bottom of the rafters, and the other to the wall (in the place where the rafters approach it), after lowering the starting bar. At the junction of two slopes (corners), we put the board not on the edge, but on the wide side. There will be a junction of two boards. It should run exactly in a straight line from the corner of the roof to the corner of the house. It turns out the design is not dependent on the wall of the building. For fastening it is better to use metal corners and plates, it will be more reliable.

Advice! The first option is used for the construction of boxes on roofs with a small slope angle. The second option is more common and is used for all types of roofs.

Before considering the rules for making a frame, it should be noted that no matter what material will be used, roof siding or lining, you must first prepare the rafters for attaching the box.

Thinking about the frame for the box should begin with the installation of the truss system. After completing the installation of the rafters, their ends protruding beyond the facade of the house must be cut to a single line. You should also check their parallelism. The distance from the walls to the end of the rafters should be the same.

The ends of the rafters are sawn off in a vertical plane. The remaining ends are hidden in the casing of the box.After trimming the rafters, the starting board of the crate is sewn to their edge. For these purposes, you can use the OSB sheet.

Proceed with the installation of the frame of the cornice should be after the insulation of the walls of the building.

The frame is done. Now we need to take care of ventilation. To do this, we insert ventilation grilles into the frame. This is done immediately, until the scaffolding is removed. When this work is done, the siding is installed.

Siding installation

To do this, you will need the siding itself, accessories for it (profiles, external and internal corners), a hammer and nails.

You should start with the crate. In our case, it is replaced by the box frame boards. The siding is mounted vertically and horizontally, for the cornice it would be more correct to choose the first option. All parts are fastened with galvanized nails.

When installing, do not forget the following rules:

- Nails are hammered strictly in the center of the oval hole;

- The cap should not strongly press the panel against the crate. A gap of 1-1.5mm is left;

- The panel must not fit snugly into the corner profiles. Experts recommend making plates 6-10mm smaller than the required size.

If you do not follow these rules over time, the siding will undergo deformation.

Mounting profiles are stuffed along the edges. Siding is then inserted into them. We measure the plates of the desired length. Slightly bend them and insert them into the profile. So we collect the entire cornice. Each subsequent panel will cling to the previous one. All panels should fit snugly into the hitch, but not stretched.

Since most often soffits are used to finish the cornices, and not the siding itself. Next, we will tell you how to attach it.

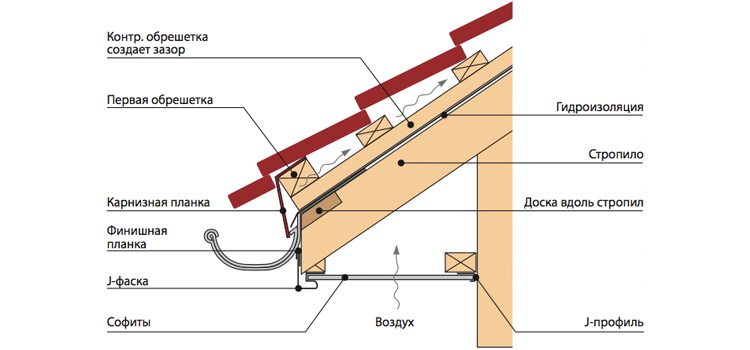

Two strips are attached along the entire length of the eaves. One from the side of the overhang, and the second from the side of the wall. J-profiles are attached to them. You can also use the F-profile, there is no fundamental difference.

We measure the width metal roof eaves, while do not forget about the thermal expansion of the material, the length of the soffit should be 6 mm less than this value. We cut the plates.

Now you need to insert the plates into the profile. Usually they are bent and wound into planks. But since the length of the cornice is not great, it is unlikely to succeed without breaking the plates. Therefore, spotlights are started from the side of the installation profile. So we collect.

When approaching a corner, the spotlights will have to be reduced in size. One of the edges is sawn at an angle of 45 degrees.

A pair of J-profiles is used to join the two sides.

It is not necessary to use two profiles, you can get by with one. Then the second edge of the spotlight, which is closer to the overhang. But with this installation option, the end face will later need to be closed with a frontal bar or chamfer.

As mentioned above, finishing the roof with siding is considered the final stage in the construction of the roof. The requirements for this work are no less high. Unscrupulous installation of the filing or improperly selected material can spoil the appearance of the entire building.

If you don't take care of do-it-yourself garage roof ventilation, for example, the thermal insulation and ventilation of the entire roof will be broken. So any work must be done in good faith.

Did the article help you?