Modern anti-icing systems for roofs, which were practically unknown to a wide range of potential buyers a few years ago, are becoming more and more in demand today. And the reason for this is their high efficiency, which allows protecting the roof from the formation of icicles and ice.

In this article, we will describe the technologies by which anti-icing roof systems are designed and created, and we will also tell you how the installation process goes.

Why do we need de-icing systems?

Ice problems

Systems whose work is aimed at combating roof icing are designed to prevent the formation of rooftops residential and utility premises of large volumes of ice, as well as the formation of icicles.

And the point here is not only in the aesthetics of the roof - there are several reasons why you need to deal with frost:

- Ice masses accumulating on the roofs during separation and fall can create a real danger to people's lives.. In addition, when ice layers fall, communications (electrical wires), fragments of the building’s decoration, as well as vehicles parked in the immediate vicinity of the building are almost always damaged.

- The accumulation of ice masses on the roof elements leads to an increase in the load on these elements.. This leads to a reduction in the service life of the roof as a whole, and with the accumulation of a significant mass of ice - to failure.

- Ice accumulated on the roof (if the anti-icing system was not installed or did not work efficiently enough) melts in the spring and during thaws, forming a significant amount of water. This water remains on the roof, as the drains are filled with ice that has not yet melted - this situation is guaranteed to lead to leaks.

Note!

You can, of course, remove the ice mechanically, but this leads to a very rapid deterioration of the roof, and its service life is rapidly reduced.

The way out in such a situation is to install an anti-icing system.

Advantages of roof anti-icing systems

Properly designed (taking into account the characteristics of the roof) and correctly installed anti-icing system makes it possible to:

- With relatively low installation costs and a low level of electricity consumption, it is possible to almost completely eliminate the formation of ice and icicles on the roof elements

- Ensure the patency of drainage channels in the cold season

- Protect the roof from leaks during thaws, as well as during the spring period of massive snowmelt

Design of anti-icing systems

Integrated approach to de-icing

The most effective way to deal with roof icing is an integrated approach, in which de-icing systems not only prevent the formation of significant masses of ice on roof elements, but also ensure that there is no ice in gutters and pipes. Cable heating systems cope with this approach as efficiently as possible.

Most of the anti-icing systems on the modern market are universal, i.e. can be used on roofs of almost any design and with gutters of almost any material (metal, plastic, etc.)

As a rule, a typical roof anti-icing system includes:

- Roof heating cable is the main element of the whole system. Anti-icing systems use cables optimized for connection to 220 V AC mains.

- Temperature controller - a device that allows you to avoid overheating of the cable

- Electrical network components - starters, residual current devices, junction boxes, etc.

- Fasteners - clips, staples, cable hooks

Heating cables for anti-icing systems

There are two main types of cables used in modern anti-icing systems:

- Self-adjusting bonds

- Resistive cables

Despite the similar principle of operation, the differences between these types of cable products are quite large:

- A resistive heating cable generates heat through resistance losses in the heating conductor. In addition to the heating core, the resistive cable contains a conductive core, which greatly simplifies the cable connection process.

- Unlike resistive, self-regulating cable is equipped with two conductive cores. The conductors in such a cable are surrounded by a special polymer, the conductivity of which depends on temperature: the lower the temperature, the more actively such a cable works.

In addition to cables for direct heating of the necessary sections of the roof, anti-icing systems are equipped with various thermal sensors that improve the energy efficiency of the entire system.

Installation of the anti-icing system

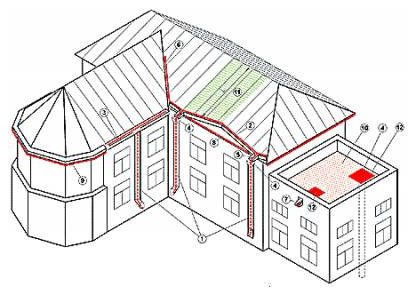

Installation of all components of the anti-icing system on the roof of the building is carried out according to the following scheme:

- First, we determine the areas where we will lay the conductive heating cable. As a rule, cable laying in valleys, gutters, drain funnels, etc. is mandatory.

- We determine the method of cable installation, depending on the material of the roof and its design.

Note!

For some roofing materials, a violation of their integrity is undesirable, therefore, in this case, it is not necessary to mount the cable using dowels and clamps.

- We install in the room or in the under-roof space (attic, attic) a control system and a junction box to which the cables will be connected.

We lay heating cables in selected places, install temperature sensors.

For fastening cables can be used:

- Cable clips with mechanical fixation - for hard roofs

- Cable clips with adhesive fixation – for soft or membrane roofing

- Fastening strips - strips of roofing material that are cut in such a way as to fix the cable

Anti-icing systems demonstrate maximum efficiency when they are designed taking into account the characteristics of the roof and the climatic conditions of your region. In this case, the selection of the appropriate elements of the anti-icing system and their competent installation also play a very important role.

Did the article help you?