The subject of this article is heating of roofs and gutters: installation, selection of equipment, areas that need to install heating elements.

In addition, we will find out what is the need for roofs in thermal power and, most importantly, why they need heating.

Goals

The main purpose of installing heating elements on the roof is to combat icing.

Where does ice come from on roofs?

- In the thaw and off-season, the lower and upper peaks of street temperature often turn out to be on opposite sides of the zero mark.. Accordingly, during the day the snow on the roof is melting, at night it freezes safely.

- If an exploited insulated attic or attic is located under the roof, heat leakage is inevitable. With insufficient thermal insulation, they can be large enough to melt snow at temperatures well below freezing.

Note: roofs where snow and ice melt at temperatures as low as -10 are characterized as "warm" and require more efficient heating to prevent icing.

If the ice on the roof melts at lower temperatures (the so-called "hot" roof), its heating becomes inefficient: in those frosts in which icing will be possible, the use of a reasonable thermal power will be insufficient to melt the ice.

What's wrong with icing?

Oh, it creates a lot of problems.

- Icicles along the edges of the roof are dangerous for passers-by and vehicles. They often reach impressive sizes and masses. Now imagine the fall of a multi-kilogram piece of ice with pointed edges from a height of 10-30 meters. Nothing good for those below, it does not promise, right?

- Ice forms not only on the roof itself, but also in gutters and vertical drainpipes. As a result of the creation of a dam, water begins to flow under the roofing material. The result is rotting rafters, damp insulation and a flooded attic.

- Finally, ice-filled drains are made too heavy for regular fastening. Its breakage means the need for expensive repairs. Don't forget about the danger to passers-by.

Facilities

How is the heating of gutters and roofs organized? There are, in fact, few options: a heating cable is used for this purpose. Let's dive into the details.

Cable types

For the purposes we are talking about, two types of cable are used:

- Resistive.

- Self-adjusting.

What is the difference?

resistive

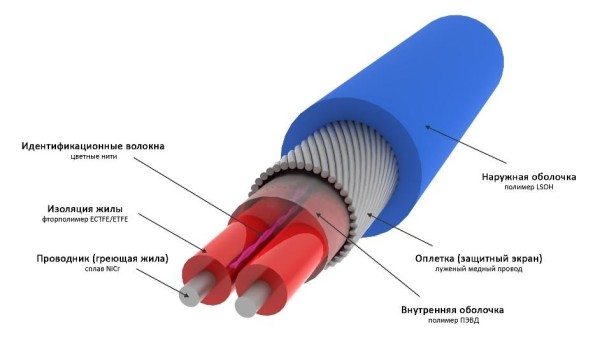

Resistive is an extremely simple heating element, which is a conductor with a fairly high resistivity in an insulating hermetic shell.

Of course, variations are possible:

- There may be one or two current-carrying conductors. In the first case, the contour must be a closed ring; in the second, the cable can be laid arbitrarily.

- Polyvinyl chloride insulation is often reinforced with additional sheaths or braids made of PTFE, fiberglass, etc.

- A cable with current flowing through it is a potential source of induced inductance in all nearby circuits. Of course, household appliances may not like such a neighborhood. The problem is solved by introducing an additional sheath made of aluminum foil or copper braid under the sheath.

The cost of a running meter of such a cable starts from only 80-90 rubles.

Relative cheapness, however, is offset by a number of disadvantages:

- A resistive cable, after power-up, heats with a constant specific power along its entire length, whether it is necessary or not. Most of the heat is uselessly dissipated in the surrounding space.

- The two-core cable must not be cut as it is a closed loop. Single core may be slightly shortened. However, here, too, a catch awaits us: with a significant decrease in the length, the total resistance of the circuit will fall, and, therefore, the current will increase. Hence - an increase in power consumption and probable overheating, up to the melting of the shell.

- Overlapping the cable will most likely again melt the sheath: too much heat will not have time to dissipate.

self-adjusting

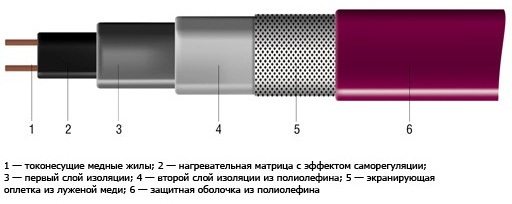

A significant part of these problems has been successfully solved in the design of a self-regulating cable. What does he represent?

Two current-carrying cores are separated along the entire length by an insert made of a polymer with a high coefficient of thermal expansion, into which a finely dispersed powder conductor is mixed (as a rule, coal dust plays this role).

How does this help automatic temperature control?

- When heated, the polymer insert expands. This increases the distance between the conductive particles and ... right, increases the resistivity. The current flowing through the polymer drops, heating decreases.

- As the temperature drops, the insert shrinks in size, accompanied by a drop in resistance, an increase in current, and an increase in heating.

What is the result?

- You can cut the cable anywhere. The length of the conductors does not have any effect on the degree of heating: after all, it is not they that heat, but the polymer-carbon insert.

- Overlaps are not terrible: in case of overheating, the cable section will simply reduce the power consumption.

- Heating of a roof and gutters becomes much more economic. The heating element dynamically reduces power consumption when heating is not needed (e.g. under warm sunlight on a dry roof or in a completely defrosted drain).

Stacking zones

Where is the heating cable installed?

- Along the edge of the slopes. There it prevents icing of the edges of the roof and the appearance of icicles.It is practiced both laying the cable in one line above the very edge, and mounting with a snake up to a meter wide.

Tip: in snowy regions above the heating zone, snow retainers will not interfere - obstacles located parallel to the edge of the slope that prevent the rapid descent of a large mass of snow.

Otherwise, both the heating cable and the drains may be damaged.

- In valleys - internal corners in which adjacent slopes converge. The width of the heating zone in them is usually from 40 to 100 centimeters.

- In the gutters. It is clear that at negative temperatures, water will freeze in them with a completely predictable result.

- In the drains. One or two cables are hung along the entire length, from top to bottom. Of course, it should not hang down outside the drain: unfortunately, no one has canceled vandalism.

- For roofs with good thermal insulation it is recommended to calculate the cable power based on 250-350 watts / m2.

- So-called "warm" roofs raise the bar to 400 watts per square.

- In the gutters and drains of "cold" roofs, the need for heat is 30-40 watts per linear meter.

- In plastic drains of "warm" roofs, a cable with a power of 40-50 watts / meter is used.

- The combination of a metal drain and a roof with poor thermal insulation is the most demanding: each meter requires up to 70 watts of heat.

Specific power

Conclusion

As always, the video in this article will offer you additional information on a topic of interest to you.Good luck!

Did the article help you?