The material of galvanized steel covered with layers of protection and painting has deservedly become one of the most popular today. Metal tile is a material that is not only affordable. Lightweight, comfortable, durable, easy to install, these, and many more advantages, made it very popular. When building a roof, you can carry out the installation of metal tiles with your own hands, but if you involve specialists for this, you still will not be hindered by knowledge of how the process should take place.

The material of galvanized steel covered with layers of protection and painting has deservedly become one of the most popular today. Metal tile is a material that is not only affordable. Lightweight, comfortable, durable, easy to install, these, and many more advantages, made it very popular. When building a roof, you can carry out the installation of metal tiles with your own hands, but if you involve specialists for this, you still will not be hindered by knowledge of how the process should take place.

In this case, you will be able to fully control the sequence and quality of the work carried out.

The sequence of actions when arranging a roof from a metal tile

- It is necessary to calculate the amount of materials. Including insulation, insulation, screws, etc.

- Equip the system of rafters, crate.

- Attach the eaves board for the future installation of gutters.

- Attach the frontal board and make the filing of the overhangs.

- Mount hooks for attaching gutters.

- Lay the waterproofing layer, then mount the counter-lattice along the rafters.

- Attach planks or boards to reinforce the structure in the right places.

- Make a cornice plank.

- Equip the lower valley.

- Lay aprons around chimneys.

- Lay the vapor barrier film.

- Under the rafters, strengthen the counter rails and lay roof insulation.

- Attach layer roof waterproofing.

- Perform the laying of metal tiles, making out at the same time dormers and observation windows.

- Install end plate.

- Design the upper valley.

- Attach adjoining planks.

- Attach ridge rails.

- Make installation of protective strips and bridges.

- Attach the gutter system around the perimeter of the roof.

- Carry out grounding work.

- Clean the roofing and touch up in the right places.

Now, knowing the order of the robot, you can begin to calculate what you need.

It should be noted that the metal tile - the installation of which you plan to carry out with your own hands, is available in a large assortment of colors.

Therefore, think in advance - in what color scheme you want to decorate your roof. So, let's take a closer look at each of the above points.

Material calculation

The metal tile is produced in the form of large sheets imitating separate fragments superimposed on each other. The sheets are full width and usable.

That is, in the end, the full width is 8-12 cm more useful. Therefore, first of all, pay attention to the working width.

Note! The number of sheets along the horizontal surface of the roof slope is calculated as follows: the length of the sheet is divided by its working width, then the result is rounded up.

The entire length of the row is calculated as follows: the slope is measured from the eaves to the ridge, the size of the cornice overhang and the size of the overlaps (0.15 m for each row) are added to the result.

Usually sheets have standard sizes from 0.7 to 12.0 m, but if you wish, you can order them to be cut to a format that is convenient for you. The most convenient, both for transportation and for installation, is a sheet with a length of 4.0 m to 4.5 m.

At the junction with a neighboring slope, the length of the sheet is selected so that it covers all the bevels entirely in all rows.

The length of the sheet is selected so that the cut point does not fall on the wave drop or step. With two sheets in one row, the length of the bottom is selected according to the wave step, adding 0.15 m, taking into account the overlap.

In order for the metal tile laid with your own hands to last for decades, the main thing is to correctly calculate not only the amount of material, but also to minimize the likelihood of cutting sheets.

Therefore, it is important, based on the size of the slopes, to choose the optimally suitable sheet sizes.

Installation of rafters

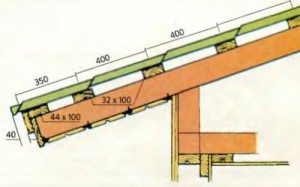

The next step after the calculations can be considered a thoughtful selection of materials and installation of the truss system.The most common sizes of rafters are considered to be boards with a section of 10 × 5 cm and 15 × 5 cm.

The step width between them is made from 60 cm to 90 cm. If there is a need to increase the step, an additional crate is performed, otherwise the sheets are likely to sag.

Make sure that the wood during construction is not wet, boards and timber should be impregnated with an antiseptic. Before starting work, measure the length and slope of the slopes again.

This must be done in order to eliminate errors when cutting boards and avoid distortions when performing the truss system.

After installing the main system, a cornice board is attached, giving additional rigidity.

Next, you should make out the frontal board, which is fastened with nails to the rafter end. The board also serves to give the structure additional strength. The filing of roof overhangs is made of lining, or special plastic or metal spotlights.

Note! It is important to leave ventilation between the sheathing and the roof space. If the binder elements are not perforated, you will have to drill one or more holes in each plank. The wood paneling is then impregnated with an antifungal compound, then painted or varnished. If desired, you can install lighting elements on the filing.

This article can be used as a guide for the installation of metal tiles, because, having studied it, you will not have problems due to inconsistency in actions.

Remember that by skipping any operation, or, considering it superfluous to perform it, you lose both the end result and the life of your future roof.

Installation of gutter hooks

The next step in the work should be the installation of special hooks - holders of future gutters. They are attached either to the rafters or to the cornice board.

In any case, it is recommended to install them before laying the final coating. Grooves are first made in the board or rafters, where the leg of the hooks is inserted, then each hook is bent into the groove and screwed with a self-tapping screw.

If, nevertheless, the hooks had to be installed after laying the tiles, then they are attached to the frontal board. In this case, it is better to use short hooks.

Installation of a roofing pie

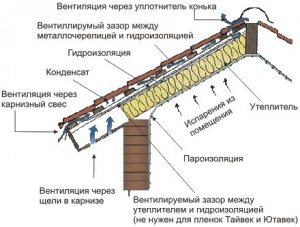

Now you can start laying vapor barrier, insulation and waterproofing. The vapor barrier film is attached to the inside of the rafters.

It is necessary so that the steam from inside the building does not fall on the insulation layer and does not cause decay. Especially in the cold season, when the room is warmer than outside, moisture condenses in the under-roof space.

Settling on a heater, it is able to quickly render it unusable.

Before you make the final installation of a metal tile with your own hands, you need to carefully prepare the base for it. From the inside, the roof is sheathed with a film, which is easiest to attach with a stapler.

Now you can lay the mineral wool insulation in one or two layers (as you prefer). It can be laid either before the vapor barrier sheathing, from the inside of the roof, or after, but from the outside of the roof.

Advice! If a cold roof is planned (for example, in an outbuilding), then an insulating layer can be dispensed with.But it’s better not to ignore waterproofing, since the likelihood of leaks increases many times over in this case.

Special waterproofing films are designed in such a way that they are able to pass and remove steam from the inside of the room, but do not let moisture into it.

There are several main categories of protective material:

- Classic type. Requires dual circuit ventilation. That is, between the insulation and the insulation layer, and between the insulation and the roofing material. The gap for ventilation in both cases should be between 30mm and 50mm.

- diffusion membranes. They need single-circuit ventilation - between them and the roofing. The membrane in this case can be laid directly on the insulation layer, the gap is from 30mm to 50mm.

- Films are anti-condensate. They need dual-circuit ventilation, with a gap, as in the first two options. Special properties of these materials are a special fleece coating. With an increased level of humidity, this coating collects a fairly large amount of water. It adheres to the coating and does not drip in the form of drops. Then, with a decrease in humidity, it simply dries and evaporates.

After the roofing cake is ready, all the accompanying elements are decorated, it is time to lay the topcoat.

Now you can consider in detail the procedure for installing metal tiles on the roof. After calculating the amount of material, purchase a drill, self-tapping screws, and you can proceed to further work.

Laying the finish coat

Since the final coating cannot be laid directly on the waterproofing, it is necessary to make a crate.

The apron around the chimney should first be arranged from the inside, picking up the adjacent strips.

The pipe should be grooved along the perimeter, making a groove about 15 mm deep, slightly sloping upwards. Then, waterproofing is removed onto the pipe, with an overlap of about 5 cm. At the exit point of the pipe, it should be wrapped with a film.

At this stage, you can complete the work, because the final finishing with an external apron must be carried out after laying the tiles.

You can proceed directly to laying tiles. It is necessary to wear soft, comfortable shoes and clothes, and take care of safety by securing yourself with a rope or safety belts.

Carefully, so as not to damage the painting of the metal tile, sheet by sheet, lift the material onto the roof.

If it is planned to lay the sheets in one row, the first fragment is placed from right to left, aligned strictly along the cornice line, and attached self-tapping screw for metal tiles in the center. This fastening is temporary, so it should only be screwed lightly. With an overlap on the previous one, lay the next sheet and fasten it to the first.

After all the sheets are laid in the same sequence and fastened together, they can be attached to the crate. The last piece in the row is not attached until the next row is laid out.

Laying in several rows, the second sheet should be laid on the first, again, from right to left, and fastened together. The third fragment is placed to the left of the initial one, and the fourth one is placed above the third one. To the crate and to each other, the sheets are initially attached lightly to facilitate alignment before the final fixing.

Each subsequent row slips under the previous one. You should move from the bottom up - from the cornice strip to the ridge.Before finally screwing the metal tile, make sure that all sheets and rows lie evenly in relation to the overhangs and to each other.

Buy self-tapping screws with heads painted in the color of the coating. They must be equipped with special washers that ensure the tightness of the mounting holes. Otherwise, water will seep under the coating in these places.

After the final attachment of the tiles to the crate, a ridge apron should be made, as well as an upper apron at the junction of the chimney. Next, a drainage system is mounted, grounding is done, antenna outputs are processed, snow retainers, etc.

Now that you have learned how to install a metal tile with your own hands, the work will be easy and hassle-free.

Did the article help you?