Recently, metal roofing has begun to gain popularity - the installation of which does not require significant effort.

Recently, metal roofing has begun to gain popularity - the installation of which does not require significant effort.

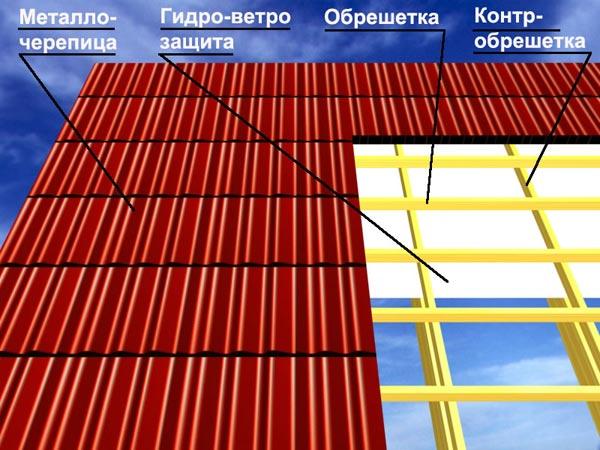

With this type of roof, the installation of metal tile sheets is carried out with an overlap, and fastening to the crate is carried out thanks to special self-tapping screws that have a sealing rubber washer.

This washer retains its elasticity regardless of temperature. True, in order to make one hundred percent tightness and proper ventilation, you need to create a full-fledged "roofing pie", for the construction of which steam and waterproofing materials are used.

The installation of metal roofing is not as laborious as the installation of slate or natural tiles, which saves on the cost of work.

Tip! If roofing with metal tiles is a difficult job for you, then seek help from specialists who will complete the work within the specified time and give guarantees, unlike those “specialists from the street” who may not be able to cope with the task.

In order for the installation of a roof made of metal tiles to be carried out in accordance with all the rules, several rules must be observed:

- Measurement and calculation. The metal tile is made or cut to the length required by the customer. Usually the length of the sheet is equal to the length of the roof slope. Installation is carried out so that the edge of the sheet protrudes 4 cm from the eaves. This is done so that there is space on the ridge for ventilation. Of course, everything is calculated according to the drawing, but, nevertheless, it is better to measure the design of the crate. You should also measure the roof diagonally to make sure it is rectangular. The number of sheets can be easily calculated by the formula in which the length of the cornice is divided by the usable width of one sheet.

Here you need to remember that each slope must be calculated individually.

- Protruding ramp. The need to ventilate the roof space from a metal tile is determined by the following factors:

- humidity of external and internal air;

- temperature differences between outdoor air and structures;

- tightness of the roof and base;

- thickness of the thermal insulation layer of the base.

In order to prevent the accumulation of moisture and condensate on the inner surface of the metal, you need high-quality waterproofing of the roof made of metal tiles, which will be mounted under the crate and provide good ventilation.

Your attention! The waterproofing carpet must be laid with an overlap, starting from the eaves and moving towards the ridge, while under the ridge a gap of at least 50 mm should be made so that moisture can evaporate unhindered.

The crate should be made in such a way that air can freely penetrate under the ridge. Ventilation holes should be installed at the highest point.

- Storage. If you will not carry out the installation of the roof for a long time, then it is advisable to lay rails between the sheets of metal tiles. In this case, you need to transfer sheets by the edges. This should be done carefully, trying not to cut your hands, as the sheets of metal tiles have very sharp edges.

- Additional processing. When installing the roof, the sheets must be cut by hand, using special metal shears or a tool designed for cutting. If the construction of a metal tile roof requires an oblique cut, then you can resort to using a hand-held circular electric saw, which has carbide cutting elements.

- Cut-off abrasive discs must not be used.

- Care. Cutting and drilling sheets leaves a large amount of sawdust that must be carefully removed, as over time it will rust and spoil the coating. In the event that the surface becomes dirty during installation, the dirt can be removed with water using a mild detergent.

- Painting. It happens that during installation the plastic layer of the coating is damaged.In this case, the zinc layer will protect the sheet from corrosion, and scratches are easily painted over with paint. The only thing you need to pay attention to is whether you have protected all the cuts of the scratch.

- Crate. If tiles are used, the roof is made from a crate of boards 30 by 100 mm. They are installed with a certain step, which depends on the type of material.

Usually this step is 30-35 cm.

It should be remembered that the board that comes out of the cornice should be 1-1.5 cm thicker than the others. When making a crate, one should not forget about the roofing elements made of metal tiles, for which fasteners must be provided.

Direct installation

For a process like covering a gable roof with a metal tile installation is carried out from the end, for a tent - from the highest point on both sides. The wave lock of each sheet must be covered by the next sheet.

In this case, installation can be carried out both from the right end, and from the left. In the event that the installation starts on the left, then each sheet must be installed under the last wave of the previous sheet. At the same time, the metal tile - the roof from which it is made, will lay down easier.

The edge of the sheet should be installed along the cornice, and fastened with a ledge of 4 cm. It is advisable to fasten several sheets, and then fix them on the ridge with one screw, then align them with the cornice and fix them along the length. After the first sheet is installed and attached, the second must be laid so that together the sheets form a straight line.

An overlap of such a design as metal tile roof, should be fastened with one screw along the top of the wave under the transverse fold formed first.

After that, the sheets are tightly joined. Only after several sheets have been fastened together and aligned with the cornice can they be finally fixed.

Fastening to the crate

It is necessary to screw the screws into the deflection of the wave of the sheet, perpendicular to the sheets. Eight screws are required per square meter. This is taking into account the fact that at the edges the sheets are attached only in the second half.

overlap places

In those places where there will be an overlap soft roof, the sheets must be installed according to the transverse pattern and fixed as described above. In the place of overlap, fastening must be done under the transverse pattern in every second wave.

Internal joint

For such joints, a standard groove bar is used. In this case, the overlap of the planks must be at least 15 cm, while the seam must be sealed with a sealing mass

You can also mount a valley at the joint. They fix it without seals using rivets or screws on top of the wave at a distance of 30-50 cm.

wind bar

This plank is fastened with screws to a wooden base. If the crate is done correctly, then the end plate will cover the end without any problems.

ridge bar

Tip! The installation of this bar should always be done only after the roof is assembled - the metal tile was used in this case or some other material does not play a role. The ridge strip must cover the entire sealing tape and all screws.

You need to fasten it with screws or rivets on every second wave of the profile.

Sealing tapes

Usually these tapes are used at the joints and under the ridge for hipped roofs. If there is waterproofing on the roof, then the tape can not be used.

Roof insulation

Metal roofing has many advantages over other materials. When purchasing this material, everyone wants it to last for many years, so it is very important that the insulation of the roof made of metal tiles is of high quality.

In order not to throw money away, you need to purchase material to look at its thickness. It should have been about 0.5 mm.

An equally important point is the presence of all the components of the roof. With a complete set, it will be possible to perform high-quality installation, which will avoid the leakage of the roof.

It is also recommended to take care of the snow retention system and moving along the roof in advance.

Did the article help you?