Roofing is one of the final stages of building a house. If the developer is not used to mindlessly spending money, then welded roll roofing is one of the most profitable options for solving the problem.

Roofing is one of the final stages of building a house. If the developer is not used to mindlessly spending money, then welded roll roofing is one of the most profitable options for solving the problem.

Relatively inexpensive and versatile material for soft roof will create a reliable shelter and save money at the same time. Such material can be used for a flat roof of any building.

The simple technology used in the installation of this version of the roof covering, as well as the affordable price for this material, contribute to the fact that the rolled-on roofing is a fairly popular option for arranging the roof.

Advantages of built-up roofing

This roof covering is not an elite option, but it occupies a fairly stable position in the building materials market. The fact is that the built-up roof has a lot of advantages over other materials, which makes developers opt for this option.

Among the main advantages:

- Light weight material. This circumstance facilitates installation and transportation.

- Modern roll-on welded roofing is easy to install and does not require regular maintenance;

- The coating, created using modern materials, is characterized by a high degree of elasticity and strength;

- The resulting coating has excellent characteristics in terms of waterproofing and protection against noise penetration;

- The created coating meets the requirements of fire safety;

- The material used to create coatings does not harm the environment. In addition, its properties make it possible to recommend built-up roofs for the purpose of economical use of energy resources.

Thus, soft built-up roofing is an excellent choice for the construction of residential buildings and a wide variety of outbuildings.

The prejudice against the use of soft roll materials is a relic of the past. Indeed, previously used cardboard-based coatings were not exposed to strength.

And the composition of bituminous impregnation included substances that adversely affect people's health.Today, materials are used based on durable, non-rotting materials. And the obsolete bitumen was replaced with polymer mixtures that are environmentally friendly.

Any construction work is carried out in accordance with the requirements of snip - soft roof is no exception. Special regulatory documents fix the rules that must be followed when carrying out roofing work, as well as when carrying out repairs to the coating.

Thus, for a construction organization, SNiPs are a kind of guide for carrying out work. Only if the installation was carried out in accordance with the requirements of building regulations, the roof will be durable and strong.

To work with each of the existing roll roofing materials, standard flow charts (TTK) have been developed, which describe the recommended scheme for the roofing process. When creating a TTK, the requirements of SNiP, SP, SN and other regulatory documents must be taken into account.

So, if a soft roof is being installed, snip II-26-76 is the main regulatory document.

In addition, the provisions of SNiP 3.04.01-87 are used, which describe insulating and finishing coatings, as well as the requirements of documents regulating labor safety during roofing and construction work.

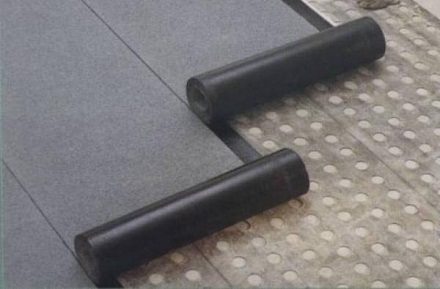

Surfacing roll materials

Today, roofing rolled welded materials are used, created on the basis of fiberglass, polyester fabric or fiberglass.

To give the material waterproofing properties, it uses a multi-layer coating with modified bituminous compounds.

Usually, soft roof mounted from two-layer materials, while the upper surface has a protective layer of sand, mica or shale chips. The lower part of the welded materials is a flammable polyethylene film.

How do the characteristics of the material change depending on the basis used for their manufacture?

- Polyester. It is considered the most reliable, but also the most expensive basis for rolled roofing material. Consists of polymer fibers arranged randomly. According to the requirements of GOST 30547-97, roofing material based on polyester must have a significant elongation at break (up to 60%), and the breaking force must be at least 35 kgf/cm. This material is highly durable and lasts a long time.

- Fiberglass. This is the base, which consists of interwoven glass strands. A distinction is made between a cheaper material based on smooth fiberglass and a more expensive one, which is made using framed fiberglass. The tensile strength of a standard fiberglass fabric is 80 kgf/cm, and the relative elongation at break is 2%

- Fiberglass. This is a material with a low degree of strength. Its quality depends on the bituminous binder used. If it has a low degree of elasticity, then the rolls are deformed during transportation and often crack when rolled out. But even if the bituminous binder is stable, rolled roofing welded materials based on glass fiber are not recommended for creating exploitable roofs, as well as for covering movable structures.The breaking strength for fiberglass is only 30 kgf / cm, and the relative elongation is 0%.

As a base coat in a process such as standard soft roof, modified bitumen is used. As a rule, polymers are used as additives:

- Styrene-butadiene-styrene (rubber)

- Atactic polypropylene (plastic).

In the first case, coatings are obtained that are distinguished by elasticity and flexibility, and in the second - a high degree of heat resistance.

Installation of built-up roof

Before proceeding with the laying of roofing material, you need to prepare the base and create a roofing cake for a soft roof.

On flat roofs, it is necessary to make a slope using expanded clay gravel and arrange funnels for a spillway. To protect the insulation material from moisture penetration from the inside, a vapor barrier membrane is used.

The next layer is insulation. It can be mineral wool or polystyrene foam. This is followed by waterproofing, which is laid with a small sag.

A solid base is mounted under a soft roof. The properties of the installed roof will depend on how well it will be done. A variety of materials can be used as a base - wood, flat slate, metal or concrete.

The cleaned base is covered with a primer, in this capacity, most often, bitumen diluted with kerosene or gasoline is used. Primer consumption should be 0.3-0.4 kg of bitumen per square meter of base.

The most difficult moment in the installation is the connection of the soft roof.

There are two ways to organize the adjoining of a soft roof to vertical walls:

- Overlap. The rolled material is laid so that it ends already on a vertical plane. On top of the roofing sheet and the vertical wall, a “junction panel” is applied, which is strengthened with the help of roofing nails to a wooden lath pre-fixed on the wall. The upper part of the cloth is covered with a metal apron.

- Fork. In this case, the junctions of the soft roof are organized as follows: the covering panel and the junction panel are attached to a rail installed on the base of the wall and roof, the junction is closed with a metal apron.

The installation technology of rolled material, in principle, is simple, welded soft roofing is installed in two ways: partial or continuous welding.

The first method is attractive in that when it is used, it is possible to avoid the formation of air bubbles, but when leaks appear, it will be much more difficult to find the location of the defect.

As a rule, the soft roof built-up is mounted in several layers. The flatter the roof, the more layers of roofing material to use.

Advice! With a roof slope of 15-20 degrees, you can make a two-layer roof, with a slope angle of 5-15 - a three-layer one. For flat roofs, four layers of material must be used.

When installing the material, gas burners are used. It is extremely important to prevent burning of the material. When the sheets are heated, they should melt, sticking to the base.

The flame of the burner must be directed to the bottom of the rolled roll. In this case, a kind of roller of molten bitumen is formed in front of the material.In addition, bitumen must also protrude along the edges of the roll, this is a guarantee of the quality of laying the material.

After laying the roll, the quality of the deposition should be checked. If necessary, pry off the edge of the material with a spatula and fix the seam using a torch.

When laying the second and subsequent layers of material, you need to slightly mix the rolls along the length and width of the slope. This is done so that the joints of different layers do not coincide.

Conclusion

Thus, soft welded roofing is the best option for roofing when you need to perform work quickly and inexpensively.

The coating, subject to the installation rules and the use of high-quality materials, is quite strong and durable.

Did the article help you?