Dropper for soft roofing, you will definitely have to deal with this additional element when installing the roof. The main purpose of this bar is to protect the roof overhangs from moisture, as well as to direct water into the gutter. Where and how to install it, we will tell in our article, and we will also describe the entire process of installing a soft roof.

Dropper for soft roofing, you will definitely have to deal with this additional element when installing the roof. The main purpose of this bar is to protect the roof overhangs from moisture, as well as to direct water into the gutter. Where and how to install it, we will tell in our article, and we will also describe the entire process of installing a soft roof.

What is a soft roof? This is a generalized name for roofing materials, the main component of which is bitumen.

But the installation of this coating is not possible without the use of additional parts, which include droppers - cornice strips.

This element protects the walls of the building and the base of the roof from atmospheric moisture and water flowing from the roof, directing its flows into the gutter, and also closes the roofing material from strong gusts of wind. That is, it is a kind of protective apron.

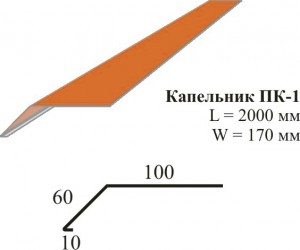

Cornice strips not only prevent rotting of wooden roof structures, but also perform an aesthetic role. They give the roof overhang a clear, even edge and close the roofing pie. Eaves strips are made of galvanized steel with an anti-corrosion layer and a polyester coating.

Their color is selected to match the main material. Droppers are installed along the entire length of the cornice overhang.

Now we propose to consider how the roof is arranged, and at what point drippers are mounted, but first we will find out what is the advantage of a soft roof over other roofing materials:

- High level of waterproofing. It is achieved due to the solidity of the roofing carpet.

- The installation process will not take much time, this will not require special tools and equipment, several people will be able to do the work.

- Roofs made of the latest generation materials perfectly cope with temperature changes and serve for quite a long time, at least 20-25 years.

- Due to its elasticity, the material is resistant to mechanical damage, smooths out irregularities and has high noise-absorbing characteristics.

- The material has a relatively low price compared to other roofing materials.

Soft roof - which is better? Let's consider each material separately.

Flexible tile - a flat sheet, from one edge of which figured patterns (rhombus, trapezium, rectangle, etc.) are cut. This material is based on pressed, non-woven fiberglass impregnated with bitumen.

Top part roof material protected by a layer of basalt dressing (shinglas, shingles) or copper (copper shingles). The bottom one is a layer of frost-resistant bitumen-polymer mass, which is protected by a silicone film (it is removed before laying).

To the main advantages soft tiles: roofing include low waste and the ability to use it on roofs of any configuration and complexity.

Roll roofing is made on a synthetic or fiberglass base, which is impregnated with bitumen-polymer materials.

This type of coating is used both in private and industrial construction. The main disadvantage is vapor permeability.

Membrane roof – made of TPO, PVC and EPDM membranes. An important feature of the installation is the fixing of the seams with hot air, which increases the strength of the coating. This material is considered strong, reliable and durable.

Installation of the roof includes several stages, consider them using the example of a roof made of flexible tiles:

- Base for mounting. First, a crate is installed under a soft roof. It should be solid, with the possibility of attaching other materials to it with nails. For these purposes, three types of wooden products are used:

- Plywood for soft roofing;

- OSB boards;

- Cutting boards.

Edged boards are stuffed with a gap of 5 mm, this is necessary for their natural expansion, under the influence of temperatures. The thickness of the board depends on the pitch of the rafters and varies from 20 to 30 mm.

Plywood under a soft roof is taken moisture resistant or tongue-and-groove. Its thickness also depends on the pitch of the rafters and ranges from 12 to 21 mm.

Speaking of OSB boards, it is worth noting that a gap of 3 mm is also allowed between them, but this is done in cases where the lathing is laid at a temperature of less than 5 degrees. Attach the crate to the rafters, self-tapping screws or brushed nails.

Advice! The moisture content of wood should not exceed 20%. All materials are treated with a special protective solution.

- Ventilation. For ventilation of the under-roof space, inlets and outlets are provided for air circulation. Entrance openings are arranged in the lower part of the roof, on the cornice overhangs. To do this, the cornice box is covered with soffit strips or special ventilation grilles are made. Exhaust openings are equipped in the upper part of the roof. To do this, a ventilated ridge or point ventilation outlets (aerators) are made. The width of the air gap should be between 50 and 80mm.

- Next, a lining layer is laid, it can be either continuous or partial (along the perimeter of the roof, at the exit points of pipes and windows, on ceilings and junctions). To do this, use rolled bituminous materials that overlap (from 10 cm and above), then nailed with roofing nails (20 cm step) to the crate.

- Drip installation. With its base, the eaves plank is attached to the upper slope, to the lining layer. The lower edge hangs from the cornice overhang. Droppers are overlapped, with an overlap of 2 cm, with nails. In the places where the planks are located on top of each other, 3 nails are nailed, nails are nailed along the edge in 10 cm increments, in a zigzag pattern (shown in the figure).

The most common mistake when installing drips is their incorrect location.

For example, if you nail a plank over waterproofing, there will be no air access, and, accordingly, ventilation as such. With proper installation, the plank is attached to the crate, under the roofing material.

It should be slightly bent from the sheathing board. Also, the width of the bar itself plays an important role. It must be taken into account here whether a gutter will be installed or not.

But first, they nail the frontal board to the overhang. Sometimes it becomes necessary to install two cornice strips (Figure 3), but this already depends on the roofing material used and the structure of the roof.

- Installation of front plates. To protect the edge of the crate, frontal strips are nailed from the ends of the roof. The technology and principle of their installation are similar to the installation of droppers.

- Installation of a valley carpet. In color, it must match the color of the flexible tile. Nails are nailed along the edge of the valley carpet, at a distance of 10 cm from each other. It is also recommended to coat the edges of the material with bituminous mastic for a more reliable grip.

- Installation of cornice tiles. A cornice tile is glued onto the dropper. The tile is glued end-to-end, and then also fixed with nails along the upper edge.

Advice! On the recommendation of specialists, cornice tiles are glued above the place of the inflection of the plank at a distance of 10-12 mm.

- Installation of ordinary tiles. The protective film is removed from the reverse side of the material. The first row is laid in such a way that its petals cover not only the joints of the cornice tiles, but almost all of it, only 1 cm should peek out. The tiles are fixed with 4 nails in the corners. Subsequent rows are stacked with a pattern shift, that is, in a checkerboard pattern. The excess is cut off with a knife with a curved blade. The edges of the tiles along the edges are smeared with bituminous mastic at a distance of 10 cm from the end.On the valleys, the tiles are cut so that an open space of 15 cm remains.

- Installation of ridge tiles. Ridge tiles are obtained by cutting the eaves into three parts. It is overlapped at a distance of 5 cm and nailed, 2 on each side. In this case, the nails are arranged in such a way that they are covered by the next tile.

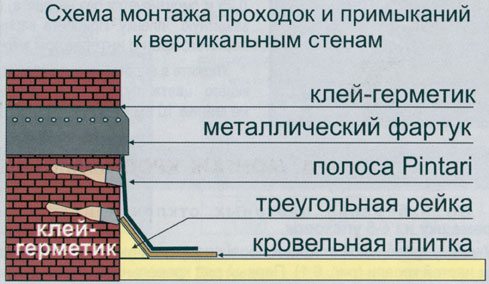

- Installation of roofing connections. These places should be given special attention. A wooden lath 50x50mm is stuffed along the perimeter of the pipes. A lining material is laid on top of it, which is fastened with nails and bituminous mastic. Next, a layer of ordinary tiles is laid, with a rise along the vertical surface by 30 cm. It is mounted using bituminous mastic. The top of an ordinary tile is covered with a metal strip, which is fastened with nails to a vertical surface, and then sealed with silicone sealant.

The instructions for installing a soft roof, as you already understood, include a set of measures, and not just the laying of flexible tiles. I would like to note that how long each of these stages is correctly performed depends on how long your roof will serve you.

Did the article help you?