Membrane roofing is a modern and high-tech type of roof finishing. It is distinguished by durability, increased strength, moisture resistance and excellent adhesion to all bitumen-based materials.

Membrane roofing is a modern and high-tech type of roof finishing. It is distinguished by durability, increased strength, moisture resistance and excellent adhesion to all bitumen-based materials.

Varieties of membrane coatings

Elastic materials based on polymers and artificial rubbers are most often used on flat and slightly sloping roofs. There are three main types of such roofing systems.

About them below.

- PVC membrane. This coating has a distinctive structure, the main component of which is polyvinyl chloride.This plasticizer has long been successfully used in the production of building, finishing and insulating materials.

To further increase the elasticity of the panels, volatile plasticizers are added to them. Polyester reinforcing mesh imparts flexibility and good elasticity to the material, which allows such membrane roofs to be mounted on roofs with a wide variety of configurations.

Compared to other types of rolled polymer coatings, PVC analogues are the most practical and cheapest, and therefore have become the most popular at the moment.

There are several advantages to using this material over conventional roofing. They do not exclude the possibility of leaks, due to the peculiarities of the arrangement.

The joints are not closed tightly, so atmospheric moisture has the ability to seep into the building. In turn, the PVC roofing membrane has almost no seams, which leads to a sharp decrease in leakage.

Note! Another advantage of this material is that there is no need to make the top layer of gravel required for conventional roll coatings. In addition, rolled PVC roofing often has a light color, and this circumstance allows it to reflect most of the sun's rays, which is very useful in summer.

- EPDM membrane. This material is reinforced with a polymer mesh, therefore it has durability and strength. Its basis is artificial rubber: ethylene propylene dieno monomer. To further increase the strength of the coating, polyester modifying additives are included in its composition. Excellent adhesion to bitumen-based materials, enhances the waterproofing properties of the coating.

The EPDM membrane for roofing is quite expensive, however, its service life, which is more than 50 years, compensates for the high price.

- TPO membrane. This high-tech product has recently appeared on the Russian roof waterproofing market. Several varieties of thermoplastic olefins are included in the basis of this roll coating.

Each manufacturer develops its own membrane formula and the ratio of ethylene-propylene rubber to polypropylene. But most often the proportion is 70%:30%.

A variety of stabilizing agents and antioxidants are added to the material to improve strength and fire resistance characteristics.

Thermoplastic membrane roofs are very similar to their thermoset counterparts, but they are based on polyvinyl chloride or similar polymers, not rubber.

PVC sheets are not chemically bonded by heating, but their shape is hermetically sealed, so they quietly keep water from getting into the seams. Similar systems for finishing roofing are not as expensive as thermosetting counterparts. However, they require more frequent repairs as well as maintenance.

Two types of such roofing sheets are produced: the first of them is reinforced with polyester, and the second, unreinforced, consists of fiberglass.

The main advantages of the material

Roofing membranes, when used, help to achieve excellent thermal and waterproofing characteristics of the topcoat.

In addition, you can lay the membrane on any type of base. Among the obvious advantages of this process is the speed of installation work.

Note! Membrane roofing is ideal for flat or slightly sloped roofs. In addition, it is possible to arrange such a coating on objects that have a complex geometric shape.

When carrying out roof repairs, using such materials, you can do without dismantling the old roofing. And this leads to a significant reduction in the cost of work.

The main thing here is to clean the base of debris, then spread the geotextile fabric in two layers, which will protect the coating from damage. Next, it is necessary, exactly according to the technology, to seal the roof.

The main advantages of polymeric membrane materials:

- Thermal resistance to seasonal temperature changes;

- High ductility, elasticity, and tensile strength;

- The minimum number of joints between rolls;

- Possibility of mounting on roofs with a non-standard design;

- Minimum installation time.

Thanks to all these qualities, the roofing membrane is becoming an increasingly popular material in modern housing construction.

Membrane installation

The thermosetting type web is mechanically attached to the base. Then the joints are heated with hot air using special equipment and welded together with an overlap.

This installation technique do-it-yourself roofs allows you to securely fix the coating and achieve the highest level of waterproofing of the entire roofing pie.

The loose fit of the panels to the base provides good ventilation of the space between them, without condensate settling. Therefore, in this case, a waterproofing subroofing membrane is not needed.

At podiums, parapets and fillet joints, the finish coating must be mounted using a heat gun. It is also used for processing joints in hard-to-reach areas.

Note! Carefully monitor the correctness of technological operations. Any violations during the installation of the roof can lead to negative consequences in the future, up to depressurization of the coating.

On warehouse and industrial buildings, structures made of metal structures, where profiled sheets act as the base of the roof pie, it is recommended to apply one or two layers of rubber-bitumen emulsion or rubber-based mastic before laying the membrane. This operation will give additional waterproofing to the entire system.

Mounting methods and mounting variations of membranes:

- Filling over the entire plane roofs ballast layer of gravel, crushed stone, etc.;

- Mechanical fixation of the coating to the base with “rocks”;

- Membrane fastening with adhesives.

Thermoplastic roofing membrane is mounted differently than thermoset counterparts.

The sequence of work is given below.

- Preparing the base for laying the coating: cleaning up debris on the roof, dismantling additional elements: transitional stairs, antennas, lightning rods, signboards, etc.;

- As necessary: partial dismantling of the old roofing, leveling the roof plane, sealing its destroyed areas, draining wet places, etc .;

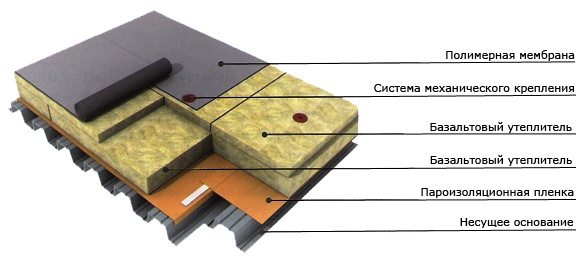

- The device of the drainage layer using geotextiles. In addition, additional insulation of the roof with hard basalt wool or extruded polystyrene foam;

- Actually laying the roll topcoat without heating the joints.

The membrane roof you have installed will create a reliable roof cladding that can last 20/30 years. Such a coating does not require the use of additional waterproofing layers, since it is itself the most moisture resistant.

Unlike ordinary roll roofing materials, as the video above shows, the installation time for membrane analogues is minimal.

It should be noted that roof repair Such coatings will require you to have certain knowledge, as well as the use of special welding equipment. Therefore, if you are not confident in your abilities, then it is better in this case to seek help from specialists.

Did the article help you?