The winning characteristics of metal tiles have left far behind the roofing materials of the last century: ceramic, bituminous tiles, slate.

Laying metal tiles video offers simple options that do not require special professionalism: an independent high-quality roof covering is quite real.

Advantages of metal tiles

- Ease of coverage: 4-7 kg/kV m significantly reduces the load on the building.

- A rich color palette guarantees harmony in the design of the house.

- High strength is ensured by the thickness of the sheet and stiffeners. If the rafters are at a distance of 1 m from each other, and the pitch of the crate is 0.3 m, then the tile with a thickness of 0.5 mm will withstand a load of up to 250 kg / kV m.

- The metal tile is not afraid of rapid temperature changes: its thermal expansion is minimal.

- It does not contain harmful components and does not release them when heated.

- Ease of partial repair roofs.

Minus: the metal tile needs soundproofing with glass wool or mineral wool insulation from rain and hail.

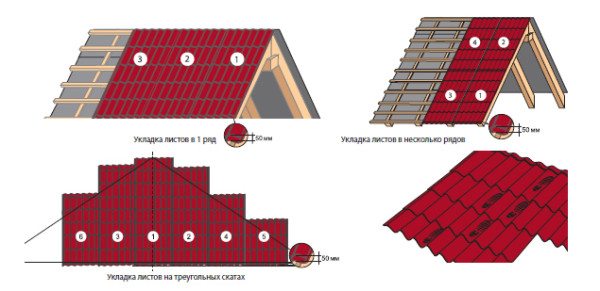

Note! The scheme of laying metal tiles is in computer programs. This will help save materials.

Types of metal tiles

Metal tile with PP

A metal tile with a protective polymer coating is sheets of aluzinc or galvanized steel, profiled by rolling. It is this method that provides the correct geometric shape.

Zinc protects against corrosion and is coated with a passivation layer to prevent the accumulation of static electricity. It also firmly holds the primer and polymers to protect against aggressive influences and impart various colors (up to 50 colors and shades).

Sheet width 1100 - 1200 mm, length 800 - 8000 mm, thickness 0.45 or 0.5 mm, profile height from 28 to 75 mm. Moreover, the higher the wave, the stronger, "more elite" and more expensive the tile.

A guarantee for a polymeric covering till 15 years. But if the procedure for laying metal tiles is followed, it will last more than 50 years.

Advice!

The greater the thickness of the sheet and the height of the wave, the stronger and more durable the roof.

Otherwise, it is difficult to avoid deformation, both during installation and from snow, hail, rain, strong wind.

Types of polymer coating

The technology of laying metal tiles depends on the characteristics of the polymer:

- Polyester – durable, but inexpensive coating: metal tile with a glossy resistant polyester coating 25 microns thick shines beautifully in the sun and withstands harmful climatic influences; matt polyester modified with Teflon already 35 microns thick with increased mechanical and color stability.

- Pural - high-quality anti-corrosion protection that can withstand temperatures of -15 - + 120 degrees.

- P50 (PUR/PrelaqNova, SSAB) has pural-like properties.

- Plastisol (P200, PVC) - the thickest and most durable coating. However, the instruction prohibits polyvinyl chloride in a number of countries as environmentally harmful.

- PVF2 (PVDF) used in polluted industrial areas: it is resistant to aggressive chemical attack and repels dirt very well. This is the most durable and practical, but expensive material.

Necessary conditions for quality installation

- The solution to the question of how to lay metal tiles, let's start by taking into account the optimal slope for such a roof - not less than 12º.

- Rafters will require antiseptic boards. They are installed in increments of 60 to 100 cm with a minimum section of 150x50 mm.

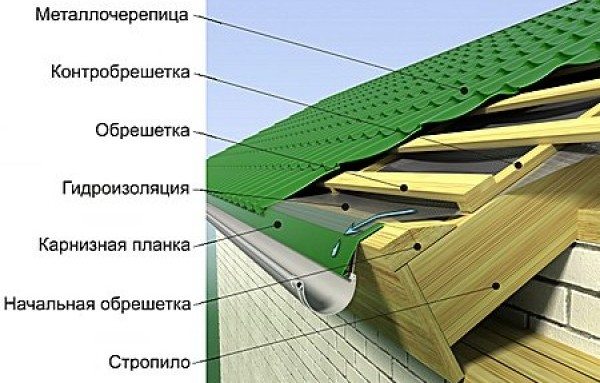

- It is better to make the crate from boards with a section of at least 25x100 mm and a step of 350-500 mm. It must correspond to the step of the wave of the metal tile and be without deflections so that snow or water does not get into them.

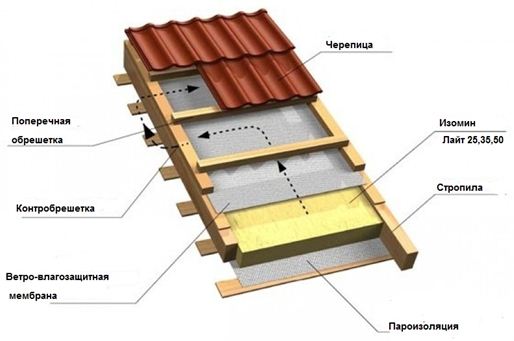

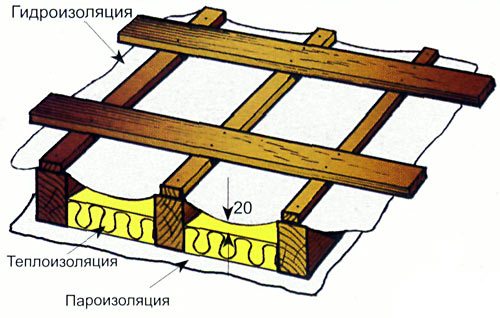

- Between the metal tile and the layer of heat and waterproofing, it is necessary to make a gap for ventilation in roofing cake. Antioxidant films are used for waterproofing.

Mounting Features

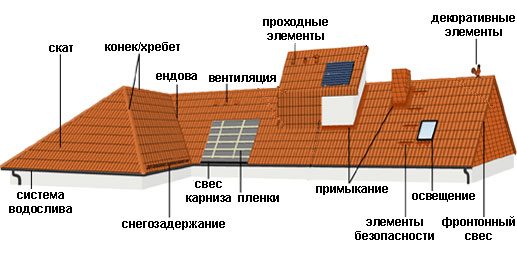

- As a rule, instructions for laying metal tiles in the form of electronic drawings, catalogs are issued upon purchase - manufacturers are interested in popularizing their product among architects, builders and independent developers. You can deal with it yourself with complex knots and fastenings of the structure, as well as step-by-step technology for erecting a roof. You should also pay attention to the joining of sheets - sellers usually have an exhibition of such joints.

- Scratches and cuts need to be painted over.

- Caution during installation: metal tiles - laying foresees the movement of roofers on a profiled roof only along concave waves, where self-tapping screws go - there is a board inside. Walking on such a roof should be in sneakers or sneakers with soft soles. Chips and debris should be swept away with a soft brush without scratching the coating.

- Grounding is also necessary for such a roof.

- After 3 months, you need to make a final tightening of the screws: they have weakened from the wind and snow.

- After laying this roof, it is necessary to make a drain.

Laying technology

A step-by-step diagram will help you decide how to properly lay the metal tile.

Step 1 Foundation

A metal tile does not require a reinforced base, but only a regular sheathing or directly on old roofs made of wood chips or wooden shingles. Sheets are fastened with screws resistant to corrosion. There is no need to pre-drill holes - these are self-tapping screws.

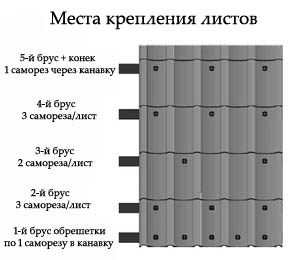

We calculate the step of the crate according to the size of the tile so that the screw is screwed into the board, and not into the void.But at the same time, one must also take into account the location of the windows: do not place the rafters above the window.

Step 2 Thermal insulation

The rules for laying metal tiles require subsequent thermal insulation, which will also save us from the noise of raindrops. We lay vapor barrier on the rafters - Yutafol or Izospan. Then we lay a heater with a thickness of up to 250 mm, which we cover with a waterproofing antioxidant film and fix it with bars to the rafters. At the same time, we calculate that the condensate always flows strictly into the drain.

Step 3 Laying sheets of metal

- Required tools: tape measure, marker, screwdriver, hammer, long rail. For cutting, you will need hand or electric shears for metal, with a fine-toothed hacksaw, electric jigsaw or a circular saw with carbide teeth, but not a grinder.

It is also impossible to cut with abrasive wheels - the sheet heats up and breaks the zinc coating, and hot chips will damage the surface of the sheet, causing subsequent corrosion.

- How to lay: the metal tile is laid very simply: the first 4 sheets must be fixed, as expected, with an overlap, but only with one self-tapping screw. Then you should align the bottom edge of these sheets with the eaves and fix them completely. Self-tapping screws should be the best - the life of the roof without repairs depends on them.

- A high-quality self-tapping screw is a galvanized screw. Its sealing head is an ethylene-propylene rubber, which, when screwed in, seals the hole tightly.

- We fix the waves down for a more dense pressing of the washer to the substrate. Otherwise, the mount will be fragile, and the roof will be “noisy” not only from rain, but also from the wind.

Step 4 Installing accessories

- Component parts, like sheets, are mounted with an overlap, which is 100 mm for inclined and 200 mm for horizontal.

- The snow retainer is fastened in each wave. At the same time, bars are placed under the metal tile at the attachment points.

- To make the roof look harmonious, it is worth buying everything you need in the kit: metal tile, drain, plugs, stairs, snow retainers, ebb, comb, storm water inlet, air duct, cornice and end strips and other details. By the way, installation plans and instructions are attached to them. Although craftsmen make these accessories from roofing steel, they are no worse than branded ones.

If you have already bought a high-quality and suitable metal tile - how to lay it: on your own or with the help of roofers - it's up to us to decide. In any case, it will now be easy to competently control the work of roofers.

Did the article help you?