Recently, we are increasingly seeing roofs covered with metal tiles. For about two decades, this material has not only been actively used, but is also rapidly gaining popularity. This is not surprising, because modern metal tile manufacturers offer the widest range of various coating configurations.

Recently, we are increasingly seeing roofs covered with metal tiles. For about two decades, this material has not only been actively used, but is also rapidly gaining popularity. This is not surprising, because modern metal tile manufacturers offer the widest range of various coating configurations.

Advantages of metal tiles

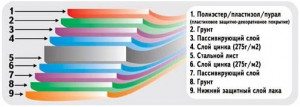

Profiled sheets from galvanized roofing steel according to GOST, covered with several layers of protection, not only look very attractive and respectable.

Note! Properly laid, such a coating lasts at least 30 years, withstands any load: wind, thick snow cover, mechanical stress. He is not afraid of rust, high and low temperatures, the influence of ultraviolet radiation, he is fire resistant and durable. The rich color scale will not leave indifferent even the most fastidious buyer.

What can surprise us today with manufacturers whose metal tiles are sold on the building materials markets?

What qualities should a material that meets modern requirements have?

- Acceptable price. For the buyer, this factor is of no small importance.

- Small weight of fragments and final construction. This greatly facilitates both transportation and installation. The rafter system for such material does not have to be strengthened additionally, which reduces time and costs.

- low cost roofing works. If you compare the prices for work, laying this material will cost much less compared to ceramic tiles or bituminous coatings.

- Long service life. Thanks to modern materials and multi-layer coating, metal tiles are not afraid of almost all weather, as well as mechanical influences. Metal tiles will last from 25 to 50 years without repair - most manufacturers guarantee this.

- A wide selection of colors and shades. Various texture solutions, variations of coatings and protective properties of the material.

Varieties of coatings

The buyer has the right to choose from a range of materials with an ideal coating for him. roofs made of metal. The basis of the material is steel coated with zinc.

Already this is enough for a long service. However, sheets additionally coated with a polymer and a layer of color will retain their properties much longer.

Note! Of the polymer coatings, polyester, pural and plastisol are most often used. Such protection in several layers makes the material resistant to temperature differences (from -50° to +120°). . He is also not afraid of corrosion, and you don’t have to worry about fire safety.

Given the rather large difference in the climatic conditions of our vast country, different metal tiles are produced - the manufacturer adapts it to a particular climate.

- Pural cover. It is considered a universal coating for the material. It is possible to use a metal tile covered with a pural not only for different climatic zones, but also for various purposes. Profiled sheets, tiles and other roofing materials can be used both for roof installation and for wall cladding and other works. The protective layer not only withstands extreme temperatures, but also quite powerful loads from snow cover, exposure to moisture and ultraviolet radiation.

- Plastisol. Plastic coating allows the material to endure cutting, deflection from loads. Scratches and chips are also not terrible for him. Moisture, wind and even severe temperature changes are easily maintained. A pleasant smooth texture allows the use of plastisol both for application to roofing material and for processing gutter systems, prolonging their service life.

- Polyester. It is widely used for coating sheets of metal. It can have both glossy and matte texture. The latter, applied to galvanized steel, gives the sheets the look of a real ceramic tile. It has a wide range of remarkable properties that allow extending the life of the coating many times over.

As we can see, the builder today has a large selection of spectacular and durable material. Fans of a smooth and shiny surface can purchase a coating to their liking.

Those who prefer the calm and tranquility of matte textures will find what suits them without any problems. It is possible to choose almost any color and shade - from the brightest and boldest, to light pastel colors.

Top Brands

The main countries producing metal tiles are Finland, Sweden and the UK. Below is a short overview of the best brands of material.

The Swedish tile "MeraSystem" is made of hot-dip galvanized steel. Most often it is covered with plastisol and polyester.

The metal tile "Monterrey" is very popular with us. It also has a polymer coating. It is universal and can be used on any type of building.

PELTI from Finland owns the Takotta brand, which is already loved by Russians for its architectural aesthetics and the highest quality. "Takotta" is made of galvanized steel, which has a thickness of 0.4/0.5mm and a zinc top layer of at least 275g/m². Then it is covered with a layer of polymer.

Poimukate is one of Finland's leaders in the production of metal tiles. Modern quality control and the use of only high-grade steel have put Poimukate shingles at the forefront of popularity.

The brand "Spanish Dune" is a new technological solution and has a hidden fastening of sheets. Therefore, holes on their outer surface are not needed. This tile completely retains its geometry, due to the rigidity of the structure.

Of the Russian companies, Metal Profile can be singled out, it is one of our first manufacturers of this material.The enterprise is equipped with machine tools manufactured by leading foreign machine-building companies.

Another Russian manufacturer of metal tiles, the Metallist company, is the owner of the Grand Line brand, which is rapidly gaining popularity among our consumers.

Did the article help you?