The rapid development of building technologies in recent decades is characterized, among other things, by the emergence of a large number of new building materials. However, ordinary galvanized roofing sheets are still very popular for roofing.

The rapid development of building technologies in recent decades is characterized, among other things, by the emergence of a large number of new building materials. However, ordinary galvanized roofing sheets are still very popular for roofing.

This popularity has a simple explanation - such a material at a low cost provides reliable insulation of the roof and interior from rain and wind.

The advantages of galvanizing are also:

- ease of installation;

- minimum scraps and waste during installation;

- durability;

- the ability to organize complex profiles.

To your attention! At the same time, galvanized roofing sheet has a significant drawback, due to which the use of galvanizing in the construction of private houses is quite rare. This disadvantage is the excessive noise of metal roofs in strong winds and during rain and hail.

Classification of galvanized steel

Roofing galvanized sheet is a rolled steel strip with a thickness of 0.4 to 0.8 mm, coated on both sides with a zinc layer with a thickness of about 0.02 mm.

Zinc is applied in two ways:

- an electrolytic method in which zinc is deposited on a steel sheet immersed in an electrolytic bath with a zinc solution under the influence of an electric current;

- hot method, in which a sheet of steel is lowered into a bath filled with molten zinc. This method gives a better, stronger and more durable coating.

For roofing, as a rule, hot-dip galvanized steel is used.

Only such steel provides the required durability of the roof with constant exposure to adverse factors - water, dust, solar ultraviolet radiation, heat and frost.

According to the surface structure, galvanized sheet steel for roofing is divided into:

- smooth;

- profiled.

Smooth galvanized steel is very convenient for mounting roofs of any shape, including the most complex reliefs. It is also convenient to make cornices, valley gutters, drainpipes, ridge tops, near-pipe aprons and other small figured elements of roofs from smooth galvanization.

Galvanized profiled roofing sheet is an excellent option for covering the roofs of industrial and utility rooms.

As a result of profiling, the rigidity of the galvanized sheet increases many times and, accordingly, the strength of the roof of the building as a whole increases.

By profiling, ordinary galvanized sheet steel roofing is transformed into a metal tile so well known to us.

Profiled galvanizing has a number of advantages that expand the scope of their application in construction:

- good mechanical strength, which allows not only to successfully withstand strong winds and large masses of snow cover in winter, but also to withstand the weight of a person during installation gable roof. This greatly simplifies the installation process;

- increased durability. Greater rigidity reduces roof vibrations under the influence of wind, which means that the deformation of the galvanized surface is reduced and the protective layers applied to it will last longer;

- ease of installation. Profiled sheets are rigid enough for two people to install them - due to rigidity, there is no need to support the sheet every one and a half meters, as is necessary with smooth sheets;

- increasing the length of the sheet up to ten meters. The reason is similar to the one in the previous paragraph - greater rigidity allows you to freely operate with longer sheets.

Profiled galvanized steel, in addition to being used for roofing, is very widely used in the construction of vertical structures - walls of industrial and warehouse buildings, fences and fences, internal partitions and other surfaces, for which low cost per square meter of surface and ease of installation play a key role.

Polymer coatings of galvanized steel

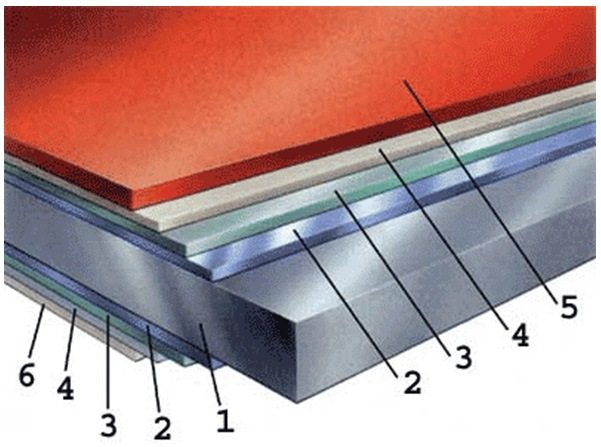

1.steel sheet;

2.zinc coating (min 275 g/m);

3.anti-corrosion coating;

4.primer;

5.polymer coating;

6.protective varnish;

Galvanized roofing sheet, in addition to classical galvanization, is often covered with various polymeric films.

The polymer film significantly increases the anti-corrosion properties of galvanizing, and, consequently, increases its durability.

In addition, the polymer film can be of absolutely any color, which opens up wide scope for the implementation of any design ideas for such a design as metal roof.

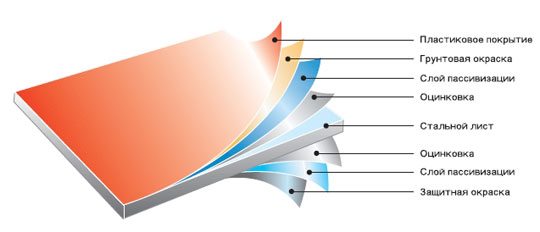

In terms of its structure, galvanized sheet for roofing with a polymer coating is more complicated than conventional galvanizing.

If we consider it in layers from the bottom up, then it consists of the following layers:

- protective paint;

- roofing steel;

- zinc;

- primer;

- protective polymer film.

Various polymers are used to cover galvanized roofing, differing in their chemical structure and properties, but providing a number of necessary properties to the finished sheet:

- resistance to solar ultraviolet, which protects the color of the roof from fading;

- mechanical resistance to scratches and minor damage;

- resistance to daily and seasonal temperature fluctuations.

The most common polymers that cover steel sheet roofing galvanized are:

- Polyester is a protective paint based on polyester. Polyester-coated metal has a glossy finish. This coating has a very high color fastness, and also tolerates fluctuations in air temperature.Polyester-coated galvanizing is cheaper than sheets with other coatings, but has a very significant drawback - due to the small film thickness, polyester is a material with very low mechanical strength. Therefore, the installation of roofing metal with a polyester film is carried out with extreme caution.

- Pural is a polyurethane protective coating for pitched roof. The thickness of the polyurethane film reaches 50 microns, which provides, in addition to high anti-corrosion properties and color stability, also good mechanical strength. Polyurethane resists chemically active liquids well, so polyurethane coated galvanizing can be used for roofing on seashores. Due to its good heat resistance, pural-coated galvanizing can be installed at temperatures down to -15ºС.

- Plastisol is a polymer film based on polyvinyl chloride with the addition of a number of plasticizers. Plastisol film is applied in layers up to two hundred microns and provides excellent mechanical strength. Galvanizing with such a coating has the highest cost, but also provides the most durable roofing in comparison with other types of roofing metal.

Delivery options for galvanized steel sheets

Galvanized roofing sheet steel is produced in width sizes from 710 to 1800 mm. Smooth sheets are produced in length up to 2500 mm.

Galvanized sheets are packed, as a rule, in multi-sheet packs, wrapped in a steel strip and covered with two steel tapes.

For automated loading and unloading, packs with a total weight of up to five tons are made. Packs intended for manual carrying have a weight of up to 80 kg.

Profiled galvanized sheet for roofing can be up to 10 meters long. It is also packed in packs, and the mass of one pack can reach up to ten tons.

Polymer-coated sheets are necessarily wrapped in polyethylene film, installed on wooden pallets, reinforced with wooden bars and covered with steel tape over the bars.

Tip! When storing and transporting profiled sheets, make sure that the supports under the pack are at least every one and a half meters. Otherwise, the sagging of the middle (or ends) of the pack can lead to a violation of the profile geometry and the impossibility of its subsequent installation.

Did the article help you?