In this article you can find out how a metal roof is made with your own hands. The technology is not very simple and requires a careful approach.

In this article you can find out how a metal roof is made with your own hands. The technology is not very simple and requires a careful approach.

Before starting the installation of a metal roof, all installation and other necessary work in accordance with SNiP 3.03.01-87 "Bearing and enclosing structures" must be completed.

The preparatory work includes the following:

- checking the slope angles of all slopes;

- checking the strength and completeness of the crate;

- checking the quality of all metal sheets and possibly sorting them.

Steel sheet metal roofing allows roof slopes from 16° to 30°.

Usually, non-galvanized (black) or galvanized roofing sheets are used for thin sheet steel roofing. The first type is used where metal roofs require restoration or major repairs.The fact is that such a sheet needs to be painted often.

The best option is to use a galvanized roofing sheet. Such a sheet corrodes less and, therefore, the service life is much longer.

A high-quality sheet is even, without lagging films, bubbles, streaks. It has a uniform dense galvanization.

In addition to galvanized sheets, roofing uses:

- roofing nails 4 x 50 mm, with a special enlarged head, are used for fastening sheets to the crate and clamps;

- nails 4 by 50-100 mm, used for attaching crutches and hooks;

- fastening clamps; they can be made from strips of cut roofing steel; used to attach roofing paintings to the crate;

- hooks; made of steel strips 5 mm thick, 16-25 mm wide and 420 mm long; used for attaching gutters;

- crutches; made of steel strips 5 mm thick, width 25-36 mm, length 450 mm; used to maintain the overhangs of the eaves;

In addition, various grips and clamps are used to secure the drain.

Nowadays, roofing screws for metal are still used.

The sheathing and rafters under the metal roofs are made of boards with a section of 200 by 50 mm and a bar with a section of 50 by 50 mm.

The bars are stuffed through 200 mm, so that the leg of a person who walks along the slope will always rest on two bars or a rafter board. This prevents the roof from sagging. For the crate, a deviation of no more than 5 mm from the control rail 1 meter long is allowed.

For a cornice overhang (roofing outside the walls), a solid boardwalk is arranged. The width of the flooring is from 3 to 4 boards with a total width of 700 mm.The front (last board) should have a straight edge and this edge should be at the same distance from the walls.

Two boards are placed along the ridge with even edges to each other. Converging edges form the joint of the ridge.

The durability of the roof depends largely on the correct manufacture of the crate. Even a slight deflection of the sheets not only reduces the density of the joints of the sheets, but also leads to breaks and leaks.

The installation of a metal roof requires 50% of the work directly on the roof, in hazardous conditions, and includes the following operations:

- laying the roof on the cornice overhangs;

- installation of wall gutters;

- laying an ordinary coating (actually covering the slopes);

- skate cover (the angle between the slopes is less than 180);

- covering the grooves (the angle between the slopes is more than 180).

Roofing iron sheets are not the lightest material, the weight of roofing steel is not small. Therefore, pre-formed roofing pictures from several sheets are lifted to the roof with the help of a truck crane in special packages.

In order not to damage the cover roofsarrange a special stand for temporary storage.

Metal roofing begins with the installation of crutches along the overhang after 700 mm. Crutches are nailed to the crate, they are designed to support the paintings on the overhang. Recede from the edge of the crate by 150 mm.

For alignment, first crutches are nailed along the edges of the eaves and a cord is pulled over them on incompletely hammered nails. The rest of the crutches are nailed along this cord.

Pictures - pre-connected several sheets of roofing. Usually - two sheets, collected on the short side.This method of roofing allows you to increase productivity and reduce your stay at height.

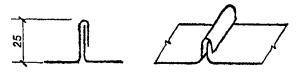

The preparation of pictures consists in bending the edges on the sheet from all sides. Then the sheets are joined with folds. There are many different devices for this process, including folding machines.

On the short side, the sheets are joined with recumbent folds for ease. runoff of water, On the long side - the connections are made standing (ridge folds). Sheets are placed along the slope with ridge folds, so that the water from the rain flows unhindered.

Seam joints are single or double.

Double connections are applied in places of the greatest presence of water:

- gutters,

- grooves.

In addition, double compounds are used for small roof pitch angles (up to 16 degrees).

The greatest labor costs are for joining pictures with ridge folds. Their length is twice as long as the recumbent ones. In addition, half of the recumbent folds are made in the workshop.

The easiest connection option is with a hammer and a special lapel bar. Now electric combing machines and manual devices - comb benders are being produced. These tools dramatically increase productivity in roofing.

Mounting roof iron, laying begins with cornice paintings. At the end of the cornices, wall gutters are laid, taking into account the installation of funnels for draining rainwater. Gutters are attached with hooks.

And finally, begin covering the roof slopes. They start from the gables, and on the hip bends - from their skates. On the gable, the overhang should be 40-50 mm. The overhang is fastened with end clamps. Together with the longitudinal bend, the clamps are bent in the form of a standing fold of double thickness.

a - e - sequence of operations

After assembling the first strip, they assemble the second one with fastening to the clamps, but with a shift of 40-50 mm, because it is necessary to part the recumbent folds. In addition, they make a shift by the same distance for the ridge folds, so that they do not converge on the ridge with the opposite slope.

Adjacent strips of paintings are connected first near the clasps, which are attached to the crate. Here the pictures are tightly attracted to it, and only then the ridge fold is connected along the entire length of the strip.

After laying the strips, the grooves are laid, the strips pre-assembled on the ground are unfolded for them. Excess iron of ordinary paintings is cut with scissors. Then the edges of the groove strip are connected with a recumbent fold, which is bent towards the groove.

For sealing, all folds must be lubricated with red lead putty.

All connections to pipes and walls are made by sealing the edge into the otter.

The article describes the technology of creating a roof using iron sheets. The order and subtleties of assembly for various forms on the roof are described, assembly and compaction methods are indicated.

Did the article help you?