All over the world, flat exploited roofs are currently very popular, especially in large cities, which are characterized by very high prices per square meter of land. This article will talk about how a flat roof is operated, as well as what modern materials can be used in its construction.

All over the world, flat exploited roofs are currently very popular, especially in large cities, which are characterized by very high prices per square meter of land. This article will talk about how a flat roof is operated, as well as what modern materials can be used in its construction.

Such roofs are widely used in European and American cities due to the ability to organize summer cafes, gardens, recreation areas, etc. right on the roof of large buildings.

In the construction of country houses, a flat exploitable roof can be used to equip greenhouses or terraces for relaxation.

Do-it-yourself flat roofing is quite difficult from an engineering point of view, since during its construction it is necessary to comply with all standards and requirements for steam, hydro and thermal insulation in order to ensure the safety of its operation and prevent collapse.

Features of the device operated flat roof

The design of the operated roof may depend on both its purpose and the type of building being erected, as well as the materials used to cover it.

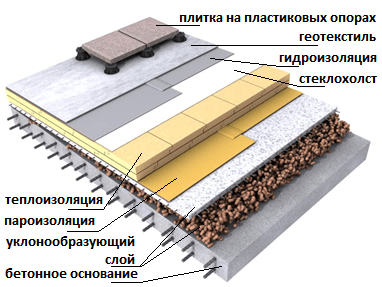

The most widespread is the following composition of a flat roof:

- Bearing slab made of reinforced concrete;

- Vapor barrier layer;

- A layer of thermal insulation material;

- Carpet waterproofing;

- The final coating, which can be made in the form of paving slabs laid on a backfill of sand and gravel or on a concrete screed when arranging on a terrace roof, or in the form of geotextile, which is laid on a drainage layer, on top of which a layer of soil is poured - during construction " green roof.

There is also an inversion version of the exploited roof, in which the insulation is not protected with a waterproofing layer, but vice versa.

The most important points for a roof, regardless of its type, are high-quality thermal and waterproofing, as well as the proper organization of the removal of water that accumulates as a result of precipitation and snowmelt.

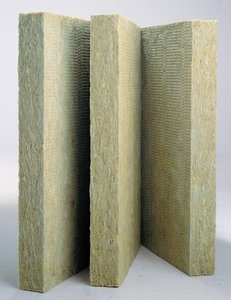

Choosing roof material to insulate an operated flat roof, one should take into account not only the coefficient of thermal conductivity, but also environmental safety, fire resistance and service life.

In addition, the material must have hydrophobicity, good vapor permeability and high compressive strength. One of the materials that meet these requirements is stone wool.

In modern construction, an exploited flat roof is quite often insulated with non-combustible materials, which is due not only to the fire safety of the roof, but also to the technological features of its construction: non-flammable insulation makes it possible to abandon the installation of heavy and expensive fire barriers.

In addition, this makes it possible to lay the built-up modern materials directly on the insulation layer, while there is no need to equip a concrete screed.

Any material used in the waterproofing of an exploited flat roof is subject to general requirements that take into account not only the standard destructive effects, but also microorganisms damaging the flat roof pie, their waste products, as well as the root systems of grown plants.

The most important characteristics of coatings used for waterproofing flat exploited roofs are:

- Good elasticity;

- Resistance to mechanical stress;

- Fire resistance;

- Preservation of basic properties in a fairly wide temperature range;

- Long service life;

- Technological effectiveness of laying the coating.

Today, the construction market offers a wide range of roofing materials: roll materials based on bitumen, fiberglass or polyester, polymeric bituminous or asphalt mastics for the roof and membranes, etc.

The listed materials have a rather high service life before repair, ranging from 15 to 75 years, so their operation is much more profitable than the use of standard roofing material.

Useful: you should also take into account the rather low resistance to plant roots, which bitumen and roofing material have: these materials are able to resist roots for a maximum of 90 days, and special anti-root additives are added to modern membranes.

In the case of the construction of a roof with a layer of vegetation, a filter layer between the drainage and the soil should be made of geotextile, which does not allow small particles of soil to be washed into the drainage, preventing silting of the drainage system and increasing its efficiency.

Important: to organize the filter layer, a special geotextile with anti-root resistance should be used.

The design of a flat roof includes another very important element - a drainage system, the device of which has its own nuances depending on the type of roof.

For inverted roofs, a funnel is used that collects water both directly from the roof surface and from the waterproofing carpet located under the insulation layer.

When using a combined exploitable roof, two drainage systems should be used in parallel, separately for the terrace and for the lawn.

At the same time, the drain for the lawn must have a reinforced layer of waterproofing. In addition, a slope device is required to allow water to flow into the catchment elements.

It can be organized by filling in crushed stone, but more modern technologies are currently being used, such as a system of valleys and skates, which allow organizing a slope even on a completely flat roof, as well as diverting water to internal drain funnels.

Modern technologies and materials for flat exploited roofs

Currently, in the construction of operated flat roofs, modern technologies and materials are used to not only speed up and facilitate their construction, but also to increase the reliability and service life of the roof.

Thus, stone wool made from gabbro-basalt rocks is increasingly being used to insulate exploited roofs. This material is distinguished by good heat and sound insulation, high resistance to external loads and a long service life.

In addition, stone wool is an environmentally friendly material. In addition to thermal insulation, this material also serves as fire protection, as it is able to withstand temperatures up to 1000º.

The disadvantage of stone wool is the increased complexity of its installation, which can be reduced by using double-density stone wool slabs, consisting of two layers that differ in density from each other: the upper layer has increased rigidity, and the lower one is less dense.

For waterproofing flat roof a fairly popular material is a polymer membrane. The service life of a polyvinyl chloride (PVC) membrane is over 30 years.

Roofs made using this membrane are distinguished by increased resistance to sunlight and combustion, in addition, the membranes are characterized by low weight, not exceeding 2 kg / m2, which significantly reduces the load on the supporting structure of the building.

The use of modern technologies and building materials allows us to build reliable and durable roofs for any needs. Properly erected exploited roof can become an integral functional component of a modern building.

Did the article help you?