One of the most difficult structural elements in the execution of almost any roof is the passage of a pipe through the roof, which creates many problems during the arrangement. This article will talk about how to properly perform this element of the roof and what measures should be taken to ensure its reliability and efficiency.

One of the most difficult structural elements in the execution of almost any roof is the passage of a pipe through the roof, which creates many problems during the arrangement. This article will talk about how to properly perform this element of the roof and what measures should be taken to ensure its reliability and efficiency.

The chimney passage through the roof attracts the special attention of various qualified specialists: both engineers and roofers and professionals working with boiler equipment.

Fireplace and boiler specialists believe that the chimney roof outlet should be located as close as possible to the ridge, which will allow the main part of the pipe to remain outside the cold zone, preventing condensation from forming and penetrating into the chimney system.

Roofing specialists recommend that the chimney pass through the roof through its ridge, which greatly simplifies the work on the manufacture of the assembly in which the pipe is adjacent to the ceiling.

In addition, this method eliminates the formation of snow pockets in winter, which, in turn, reduces the risk of leaks at the junction of the roof.

Another fairly successful way in which the passage of the chimney through gable roof, consists in placing the pipe on the surface of the slope at a small distance from the ridge.

To protect the chimney from precipitation, it is recommended to cover the mouth of this pipe with a special umbrella made of the same material as the roof itself.

Important: in case of connecting the chimney through the boiler equipment, it is not recommended to use an umbrella, since the combustion products have a rather low temperature, which will create an obstacle to the release of gases.

The most problematic node for the passage of the pipe through the roof is the exit of the pipe through the roof with insulation, the design of which is made in the form of a “layer cake”.

In the case of using a roof of a similar design, it is recommended to use a separate box to remove the chimney pipe.

Important: rafters and beams in the roof structure must be located in accordance with the requirements of SNiP, and the space surrounding the chimney must be filled with heat-insulating non-combustible material. For example, stone wool is a good sealant for roof penetrations.

The passage through the roof can vary depending on the material from which the chimney is made, as well as on what shape its section has:

- Rectangular;

- oval;

- round;

- Square.

If the pipe is exited through the ceiling, then care should be taken to ensure the quality of such a moment as roof waterproofing.

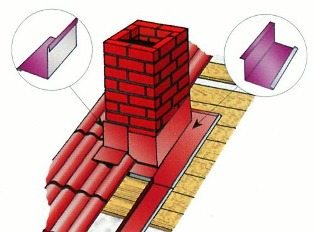

To do this, an apron is arranged around the chimney, which can be made of roofing material for pipes with a rectangular or square section, the outer walls of which are lined with brick, or from an elastic tape with an adhesive layer around the edges, which is based on lead and aluminum.

One end of the tape is glued to the pipe, the other to the roof, after which the upper part of the tape is pressed with a metal bar and fixed with heat-resistant dowels.

Removing the pipe through the roof

When removing the pipe through the roof and ceiling, it is necessary to solve two problems at once:

- Passages through the roof should be as safe as possible from a fire point of view, and the pipe passes through the roof pie and ceilings, which can be combustible in themselves.

- The interior of the house should be protected as much as possible from the penetration of wind and moisture through the pipes.

One of the advantages of bringing the pipe to the ridge is the ease of connecting the pipe to the roof covering.There are no pockets of snow on the roof ridge, which significantly reduces the risk of leaks.

The disadvantage of this method is the absence of a ridge bearing beam in the construction of the rafters, or the need to make a gap in the beam in the place where the chimney will pass, requiring the installation of additional rafter supports, which can be especially inconvenient if there is an attic.

Therefore, most often the pipe is led out on a slope next to the ridge, where there is also no snow bag, and the knot is also quite simple.

Important: you should not equip the chimney in the valley - the place of convergence at an angle from the inside of two roof slopes, since at this point it is very difficult to qualitatively connect the pipe to the roof. During rains, rainwater will flow here, and in winter, a large snow pocket will appear in the valley, which will lead to leaks at any time of the year.

The distance between the roof and the rafters should also be observed, which should be 25-30 centimeters, and in the case of combustible roofing material, leave a gap of 13-25 cm to prevent fire, on a roof such as, for example,

In the case of a non-combustible coating material, the gap can be reduced to a few centimeters, and the pipe should be removed only from the crate itself.

If the roof structure is made in the form of a roofing pie, consisting of layers of vapor, hydro and thermal insulation, certain difficulties may arise during the installation of the chimney assembly, associated with the need to break the continuity of the vapor and waterproofing layer, leading to a decrease in the protection of the insulation layer.

In this case, the most acceptable way is to isolate the space adjacent to the pipe from the rest of the roof, which consists in making a separate box for the chimney, which can be made of wooden beams and rafters.

The distance between its walls and the chimney should be 13-15 centimeters, and the space around the chimney should be filled with heat-insulating non-combustible material, such as stone wool.

This material receives less damage from exposure to moisture than other heaters, so you can not arrange hydro and vapor barrier here.

The supply of vapor and waterproofing to the box itself is carried out by the standard method: they cut the film sheet in the form of an envelope, bring it to the edges of the transverse beams and rafters and fix it with staples or nails.

Next, the waterproofing layer is pressed with sheathing bars, and the vapor barrier layer is pressed with the frame of the attic finishing material, after which the joints of the box and films are sealed with special compounds or tapes to improve tightness.

Joint leak prevention

To ensure the most hermetic adjoining of the roofing material to the chimney pipe at this point, an internal apron is made using the lower abutment strips.

To do this, apply a bar to the walls of the chimney pipe and mark the upper part of the bar on the wall, after which they punch a strobe along the marked line.

They begin to install the inner apron from the bottom wall, leading the edge of the apron into the gate, after which they install it on the remaining walls, leaving an overlap of 15 centimeters and sealing the edge of the film inserted earlier into the gate. Next, cut the lower strips, install them and fix them with self-tapping screws.

After the bottom apron is mounted, they begin to install a tie that provides water drainage and is a sheet of waterproofing material wound under the elements of the inner apron located below.

On top of the tie and the inner apron, which provide reliable protection for the junction of the roof and the pipe, the roofing material is laid, after which a decorative outer apron is installed, for which the upper adjoining strips are used.

The installation of the outer apron is carried out similarly to the installation of the inner one, except that the upper edge is attached directly to the wall of the chimney without using a strobe.

Useful: at present, the construction market offers products designed specifically for chimneys with a circular cross section - roof passages consisting of a base in the form of a steel flat sheet connected to an apron cap, inside which a round chimney is carried out.

An apron, made independently or purchased ready-made, should be securely fixed to the roof structure, while it is not recommended to connect it too tightly with the chimney itself, which can cause damage to the structure when the roof shrinks or the pipe expands and contracts under the influence of temperatures.

At the junction of the pipe and the apron, it is recommended to use a skirt - a special steel clamp, which is fixed with a heat-resistant elastic gasket. This method also improves the waterproofing of the apron.

Did the article help you?