This article will talk about what roof waterproofing is and what it is intended for, as well as what materials are used to waterproof the roof itself and its individual elements.

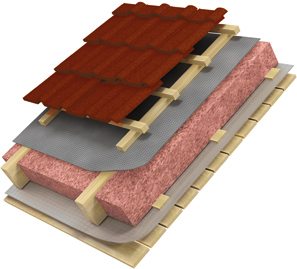

The roof covering should primarily protect the roof from precipitation, but there is also a risk of mechanical damage to the roof, as well as the penetration of water or snow into the gaps formed between the elements of the laid covering.

To prevent such troubles, roof waterproofing is intended - a video about its installation can be found on the Internet.

Roof waterproofing primarily protects the roof from moisture penetrating under it from the outside, leading to rotting of the wooden elements of the roof structure and reducing the effectiveness of wet insulation material.

The temperatures under the insulated roof and outside are significantly different, which leads to the condensation of moisture contained in the atmospheric air on the elements of the roof pie, which have a low temperature.

When using a variety of roofing materials, condensation on the inner surface is unavoidable. In this case, roofing waterproofing also performs additional protection of the insulation from condensate.

In addition, sometimes the “dew point” is formed directly inside the insulation layer, as well as on roofing elements made of wood, so the roof structure must necessarily include ventilation circuits that allow water vapor to be removed from the under-roof space before they occur. condensation.

Roofing and waterproofing material are also part of this ventilation system, the type of which depends on which materials are used.

In addition to the circuit between the roof and waterproofing, the ventilation system may include a second circuit located between the layers of insulation and waterproofing.

Indicators that the installation of roof waterproofing is carried out in accordance with the rules and regulations are:

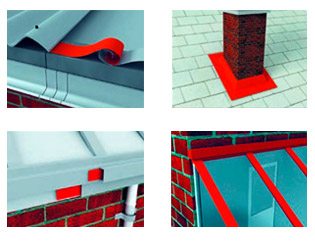

- The arrangement of waterproofing is carried out under the entire roof covering, including the overhangs of gables and cornices;

- The lower sheet of waterproofing is brought out beyond the boundaries of the eaves into the drain or onto the frontal board;

- The waterproofing film for the roof securely adjoins the pipes and walls on the roof.

Roof vapor barrier

In any living space, water vapor is formed, which, in accordance with the laws of physics, rises from the bottom up, ending up in the under-roof space, causing the layer of material located there to become wet, such as roof insulation.

In order to keep the insulation material dry, it is imperative to carry out a vapor barrier layer in the roofing cake.

In case impervious steam is used for finishing attic walls roof material, this may be sufficient to ensure dryness roof insulation.

In most cases, additional installation of a vapor barrier film is required between the ceiling and the thermal insulation layer, and it is desirable that the film adjoins the insulation.

The most important characteristic of a film used to create a vapor barrier is vapor barrier, which is determined by its density, expressed in g / m2. Higher density provides better vapor barrier film.

Another important film quality is tear resistance, which results from two factors:

- When the elasticity of the insulation layer is lost, its weight is transferred from the rafter system to the vapor barrier, which must withstand this load.

- In the event of mechanical deformation of the roof structure, the film must also withstand the load, ensuring that the integrity of the vapor barrier is maintained.

Water vapor has a high penetrating power, therefore, the arrangement of vapor barrier should be approached with all responsibility, in particular - to carefully seal the seams of the material used for vapor barrier, as well as the places where it adjoins the elements of the rafter system, walls, chimney and ventilation pipes and other passage elements of the roof .

Useful: the most effective method of sealing is considered to be gluing the joints with self-adhesive butyl rubber double-sided tape.

Most often, the following roofing and waterproofing materials are used to provide hydro- and vapor barrier of the roof:

- Polyethylene film providing both hydro and vapor barrier;

- Polypropylene film - a waterproofing film for roofing, practically unsuitable as a vapor barrier;

- The material with which only waterproofing of the roof is made is a “breathing” non-woven membrane.

The main purpose of these materials is to protect the roof structure from the penetration of moisture and water vapor.

Waterproofing materials

In different regions of the planet, there are different climatic conditions that have a variety of negative effects on the roof, for example, low and high temperatures in themselves are much less dangerous than their abrupt change.

In addition, it is important to take into account the differences in the direct structures of the roof, as well as the loads acting on the roof and its waterproofing.

Therefore, in order to improve operating conditions, new waterproofing and roofing materials are constantly being developed, designed for operation in regions with different conditions and for various roof structures.

The quality of materials improves with the improvement of production technologies, significantly expanding the range of different conditions that allow the use of a particular material over a wider temperature range.

Materials for vapor and waterproofing, first of all, must ensure the operation of thermal insulation in the required mode, performing the following functions for this:

- Prevention of moisture penetration into the insulation material, which significantly reduces its thermal insulation performance and often leads to its gradually increasing destruction;

- Direct participation in the process of ventilation of the under-roof space, which eliminates the accumulation of moisture in the thermal insulation layer and improves the removal of water vapor to the outside.

Films for waterproofing should be used in the construction of pitched roofs, the coating of which does not form a continuous carpet.

Such coatings include tiles of all kinds, metal materials and slate. In addition, the films provide protection against moisture from the outside (rain, snow or condensation) penetrating under the roof covering during strong winds or heavy rains.

Vapor barrier films should be used for both flat and pitched roofs, regardless of the type of covering, as they protect the thermal insulation layer from water vapor penetrating from the interior, where it is formed as a result of human activity.

Processes such as cooking, washing, mopping, bathing, etc.lead to the emergence of water vapor, which rise up - into the space under the roof as a result of convection and diffusion.

Below is a table by the manufacturer of roofing materials (Footnote 2) technical characteristics of the waterproofing material SAFETY FLEX

| Name | Unit rev. | EPP | EKP Endova (with 2 adhesive zones) | ||

| The basis | — | non-woven polyester fabric (polyester) | non-woven polyester fabric (polyester) | ||

| Type of protective coating, top/bottom | — | film / film | basalt * / film | ||

| bitumen type | — | APP - modified | APP - modified | ||

| Welded side weight | kg/sq.m. | > 2 | > 2 | ||

| Base weight | g/m.sq. | 140 | 190 | ||

| Breaking strength in the longitudinal / transverse direction, not less than | H/5cm | 500 / 400 | 600 / 450 | ||

| Flexibility on the beam | °C | < -15 | < -10 | ||

| Elongation at break | % | > 30 | > 30 | ||

| Peel strength | H | > 100 | — | ||

| Fraas brittleness temperature | °C | -20 | <-15 | ||

| Heat resistance, not less | °C | > 120 | > 100 | ||

| Waterproof | 60kPa/24h | absolute | absolute | ||

| Vapor permeability | µ | > 20000 | — | ||

| Thickness | mm | 3 | 4 | 5 | — |

| Length x width | m | 10 x 1 | 8 x 1 | 6 x 1 | 10 x 1 |

| Number of rolls per pallet | PC | 25 | 25 | 25 | 25 |

| Quantity of material on a pallet | sq.m. | 250 | 250 | 150 | 250 |

| Material weight on 1 pallet | kg | 900 | 960 | 900 | 1000 |

Materials used for waterproofing individual roof elements

Such important characteristics of the roof as reliability, efficiency, safety, functionality and others largely depend on its waterproofing, and not only the waterproofing of the roof surface itself is important, but also the various elements present on it.

In modern construction, quite complex materials are used for waterproofing, designed to provide the highest quality protection against penetrating moisture.

Modern waterproofing materials include, for example, waterproofing roofing mastic or bitumen, the main advantages of which are:

- Good adhesion to most types of surfaces;

- High strength;

- Long service life;

- Completely waterproof, etc.

These materials are used to protect the entire structure or individual elements of the roof from moisture. In this case, it should be taken into account how the material used for waterproofing is combined with the material for roofing (finishing layer).

Depending on which type of roofing material is chosen for covering, vapor permeable or vapor absorbing materials are used for waterproofing.

Important: when installing a waterproofing material, it should be positioned correctly, taking into account which side of the film should be directed towards the insulation, and which side should be directed towards the roof pie, since regardless of the quality of the vapor barrier, a small amount of steam enters the insulation in any case.

There are three main types of modern materials for vapor and waterproofing:

- Superdiffusion membranes that do not allow moisture to pass through, but let its vapor pass through. The vapor permeability of this material allows its installation close to the insulation material, leaving no lower gap for ventilation;

- Waterproofing diffusion membranes, which are films with tiny holes made in the form of funnels facing inward with a wide side. This material allows steam to pass through without passing water and requires top and bottom ventilation gaps;

- Waterproofing anti-condensation membranes impervious to steam and water. These membranes are used mainly for euroslate and metal tiles and require two ventilation gaps.

While building a house, it should be remembered that roof waterproofing is the most important stage of construction, on which the effectiveness of roof thermal insulation directly depends.

Properly executed waterproofing using well-chosen materials will keep the heat in the interior and ensure comfortable living in the house for many years.

Did the article help you?