In winter, the formation of icicles on roofs can pose a significant danger to human life and health. This article will talk about how roof heating is carried out, what equipment is used and how this equipment is installed.

In winter, the formation of icicles on roofs can pose a significant danger to human life and health. This article will talk about how roof heating is carried out, what equipment is used and how this equipment is installed.

Icicles on the roofs are the result of the so-called frequent zero crossing, when in winter it often changes from a positive day to a negative night.

Regardless of the type of roof, heating is needed in order to prevent the formation of icicles that seriously threaten the life and health of people passing under them.

The formation of icicles on the roofs, as well as the occurrence of ice in the gutters during the cold season, is a common occurrence for the climatic conditions of our country. The main reason for the appearance of these processes is the release of heat from the interior of the building through the roof.

The following factors may contribute to this:

- frequent transitions through zero air temperature;

- complex roof structures;

- mistakes made when designing the space under the roof;

- miscalculations made during the construction of buildings;

- excessive savings on the construction of the roof.

In addition to the risk for passers-by, icicles and ice create other problems, such as: the appearance of leaks in the roof; the destructive effect on the building of ice resulting from the freezing of water in various cracks and cracks; increased load on the roof and load-bearing system of the building, etc.

To combat the occurrence of ice and icicles on the roofs, the following methods are currently used:

- Mechanical cleaning of roofs, which is the most common method, but has a number of disadvantages. For example, this requires maintaining a whole staff of specially trained employees, as well as using various special vehicles during work, such as aerial platforms for work. on the very roof, which causes the closure of both highways and sidewalks for pedestrians. In addition, this method can lead to damage to both the roof itself and its other elements, including gutters, and also poses a certain danger to people involved in cleaning the roof.

- Heating roofs and gutters is a more modern and safe method of getting rid of icicles and ice.In the case of the correct equipment of the heating system, this method has a number of advantages compared to the first method. The main disadvantage is the significant consumption of electrical energy, which, however, can be reduced by almost half by using an automatic control system.

- Another device method roofs without icicles and ice is the use of electric impulse systems, less common than snow melting systems. Installing these systems is a rather expensive undertaking, but during operation they consume much less electricity than cable heating of the roof. The disadvantage of electric impulse systems is the ability to protect only the edges of the roof from icicles and ice, while pipes and trays remain unprotected.

- The least popular way due to its high cost, short duration and various difficulties in the application process on the roof and its subsequent use is the use of special emulsions to combat icing.

Roof cable heating system

Where: 1- drainpipes; 2-drainage gutters; 3 trays for collecting water; 4 funnels and the area around them; 5-guide tray; 6-endova; 7-water cannon; 8-cornice; 9-dropper; 10- flat roof; 11-catchment area of the gutter; 12-area of input heating; 13-edge of the roof; 14-snow guard.

In order to avoid the appearance of icicles, it is not necessary to fully heat the roof - it is enough to lay the heating cable in places where heating is most needed.

The diagram shows the most problematic areas of any type of roof, where the installation of a snow melting system is appropriate.

Most often, if the heating cable for the roof is installed in the areas marked on the diagram, it turns out to be enough to protect both the edges of the roof and downpipes and trays from the appearance of icicles and ice.

Roof heating cable system includes the following elements:

- Roof heating cable, the power of which can be either constant linear, ranging from 20 to 30 W / m, or self-regulating, that is, changing in accordance with changes in various external conditions;

- Special elements that are used to fasten heating cables to roofing elements, as well as gutters and snow retention;

- Distribution network, including power cables, as well as boxes that distribute the supply voltage and connect the heating cables to the network

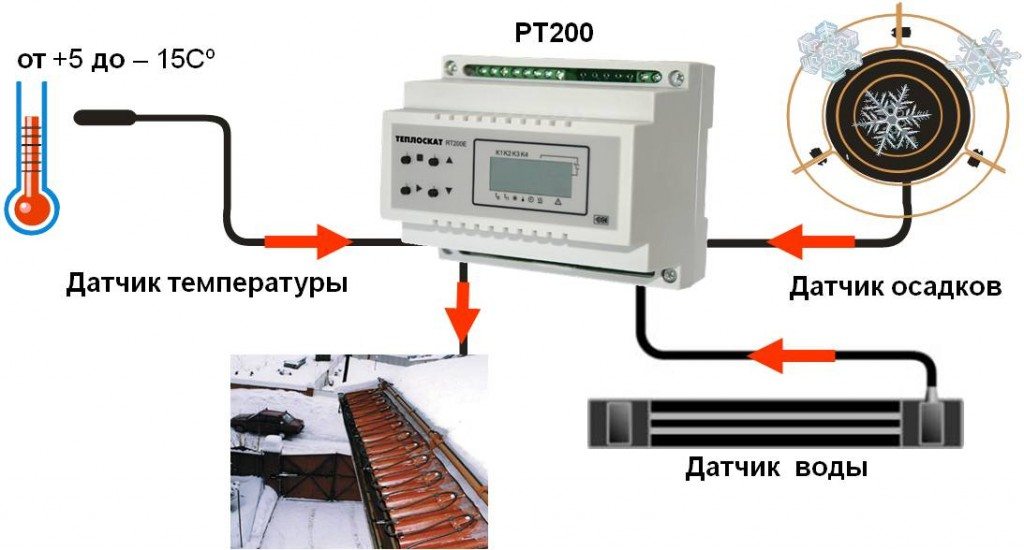

- Elements that carry out automatic control and management of the operation of the system that heats gutters and roofs. They include an ambient temperature sensor, a precipitation sensor, a melt water sensor and a temperature controller.

- Starting and regulating equipment, which is part of the system control cabinet, including magnetic starters and automatic protective switches that supply voltage to the cable that heats the flat roof.

Installation of a roof heating system

Where: 1. Temperature controller RT330; 2. Temperature controller RT220; 3. Precipitation sensor power supply; 4.Air temperature sensor TST01 for PT220; 5. TST05 air temperature sensor for PT330; 6. Precipitation sensor TSP02; 7. Water sensor TSW01

The installation of a roof heating system begins with the assembly of the roof heating cable into sections ready for laying. For this, it is tied using special clamps.

Next, the resulting sections are placed in trays, which are lowered into pipes and laid out along the edge of the roof with a snake, after which they are fixed with special rivets, strips and clamps.

After that, the distribution network is mounted from the installation site of the cabinet that automatically controls the heating system to the installation sites of distribution boxes, which are preferably installed at a minimum distance from the heating cable couplings.

Important: the installation locations of the boxes and the cabinet should be planned in advance in order to avoid difficulties when laying the distribution network.

The final stage is the installation of a cabinet for automatic control of the roof heating system and its connection to the previously installed distribution network.

After installation is completed, it is imperative to perform the commissioning procedures provided for by the requirements and norms of Chapter 1.8 of the PUE:

- Measure the resistance of all used cables (power, heating and control cables);

- Measure the resistance of the cores of heating cables that conduct current and clarify their compliance with the values \u200b\u200bspecified in the passport;

- Perform a system ground test;

- Measure the parameters at which the devices that turn off the heating system for protective purposes are triggered;

- Measure the phase-zero loop;

- Check the correct operation of the automatic control system;

Based on the results of commissioning and commissioning, a technical report is drawn up, after which it is possible to start operating the roof heating system.

The principle of operation of the automatic control of the roof heating system

In the case when the ambient temperature falls within the operating range, relay K1 is turned on, which removes the blocking from the load control circuits.

If the timer, which turns on heating when the temperature enters this range, was turned on, then roof heating starts for the period of time specified by the timer, after which the system turns off and the device monitors precipitation and water sensors.

In the event of precipitation, the heating modes of the roof and trays are switched on, for which relays K2 and K3 are responsible, after the precipitation ends, with the help of relay K2, the roof heating is turned off, but the heating of the trays continues, heating the pipes until the signal disappears from the melt water sensor.

Further, the heating of pipes and trays continues to work for some time during the delay time set by the built-in timer, after which the system turns off.

Did the article help you?