For better heating of the roof in the autumn and autumn periods, a heating cable for the roof is often used. This article will talk about what a heating cable is, how it is installed and what types of heating cable are used on roofs of various structures.

For better heating of the roof in the autumn and autumn periods, a heating cable for the roof is often used. This article will talk about what a heating cable is, how it is installed and what types of heating cable are used on roofs of various structures.

The main functions of heating cables are the complete prevention of ice formation on the roof and ensuring the efficient operation of the gutter system in autumn and spring.

It should be borne in mind that roof heating systems work effectively only in spring and autumn, and in winter they are turned on only during thaws, since at air temperatures below -15º these systems are not only useless, but can also cause some damage to the roof for several reasons:

- At a fairly low air temperature, moisture is not formed along the contour of the first mechanism, and the amount of moisture along the contour of the second mechanism is significantly reduced;

- The amount of snow on the roof, which falls in the form of precipitation, is also significantly reduced;

- The removal of moisture and the melting of snow require quite significant electrical capacities.

When heating the roof with your own hands, you should remember that a temperature sensor must be installed in the system, as well as an appropriate specialized thermostat, which is, in fact, a miniature weather station.

The temperature controller not only controls the operation of the entire system, but also allows you to adjust various temperature parameters, taking into account the specific features of a particular climatic zone, as well as the number of storeys and location of the building.

Heating cable installation

Installation of cables that carry out electrical heating of the roof is carried out along the entire route of the melt water.

Cable installation begins with horizontal trays and gutters, and ends with the outlets of the drainage system, as well as collectors at a depth below the freezing level of water, if the building is equipped with storm sewers.

Important: during the installation of heating cables, it is necessary to ensure free flow from the roof of the water formed as a result of the work.

When performing electric heating of the roof, it is necessary to comply with various standards that regulate both the power of the cables themselves and the power of various elements of the heating system.

Violations of such requirements lead to a decrease in the efficiency of the system for a given temperature range, and their significant excess also causes excessive consumption of electrical power, which is not accompanied by an increase in work efficiency.

These standards include the following:

- Specific power of cables for heating, which are installed on horizontal roof elements. The specific total power per unit surface area of the heated element, such as gutters, trays, etc., must be at least 180-250 W / m2;

- The specific power of the cable located in the drains is at least 25-30 watts per meter of its length, with an increase in the length of the drain, the power value can increase to 60-70 W / m.

It is important that the knots used to secure the cables are made from the same materials used in the construction of the roof, or materials that are compatible with roofing materials.

Fastening points should be made durable and reliable, not causing damage to the sheath of cables that perform roof heating.

When heating soft roofs, special fastening methods are used that do not cause damage to the cable.

In addition, the laying of the heating cable in the rather popular snow removal and snow retention trays can be carried out using a cement-sand or concrete screed, which will not only prevent damage to the cable, but will also significantly increase the heating efficiency due to the ability of concrete to accumulate heat.

Separate requirements are imposed on electrical and fire safety when laying a heating cable, including the following conditions:

- Heating cables that are part of the heating system must have appropriate certificates, including a fire safety certificate, which is most often supplied with cables that are not subject to combustion. In addition, for the use of cables in anti-icing systems, you should have recommendations from the manufacturer;

- The part of the system that performs heating must be equipped with either an RCD or a differential circuit breaker, the leakage current of which does not exceed 30 mA, and for electrical safety requirements it does not exceed 10 mA;

- Complex anti-icing systems must be divided into separate zones, the leakage currents in each of which must comply with the above requirements.

Major manufacturers supply their heating cables with all required certificates confirming their repeated approbation when used in anti-icing systems.

Major manufacturers supply their heating cables with all required certificates confirming their repeated approbation when used in anti-icing systems.

There are two types of tests for icing systems:

- Acceptance tests, which usually begin with a test of the insulation resistance of distribution and heating cables, after which RCDs or differential machines are tested and protocols are drawn up that indicate the values \u200b\u200bobtained as a result of the tests.The most complete information can be obtained from performance test reports, which test the effectiveness of the system.

- Periodic tests are usually carried out in September to check the technical condition of the system and its readiness for operation. First, the insulation resistance is checked and the search for damaged elements is performed, after which the state of the equipment is tested and its test run is carried out. Next, they check the settings of the thermostats and perform a working start of the system, leaving it to work in standby mode.

Installation of heating cables on roofs of various configurations

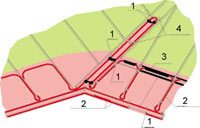

Valley heating example:

- clamp;

- heating section;

- Mounting bracket;

- Copper strip.

In modern construction, a wide variety of structures are used, which becomes possible due to the use of the most modern technologies and materials that allow the implementation of the most daring design and architectural solutions, for example, the upper floors of buildings are increasingly being equipped in the form of attics.

The absence of a cold attic under the roof leads to additional heating of the roof not only from the outside, but also from the interior, as a result of which snow melts unevenly and part of the melt water freezes in other parts of the drain and roof.

This can lead to a variety of negative consequences:

- Education on the roof icicles;

- Breakage of gutters;

- Gutter rupture;

- The appearance of "salt plaque" on the facade;

- Violation on flat roofs of the upper layer of roofing material;

- The formation of cracks at the joints of metal sheets, etc.

When installing a heating cable on pitched roofs, it must be installed in all gutters and pipes of the drainage system located along the perimeter of the roof. The cable can be laid in most places on the edge of the roof, as well as in valleys located on the north side.

Useful: if there is no gutter at the edge of the pitched roof and icicles form, then a cable should also be run under the edge of the roof to “cut off” the icicles.

For flat roofs, it is obligatory to lay the cable in drainpipes located outside the knowledge; a roof funnel with electric heating is mounted.

The cable is fastened using plastic or metal elements, depending on the material from which the roof and gutters are made.

Important: when fixing the cable, care should be taken to maintain the integrity of the top layer of the roof covering, therefore it is not recommended to use rivets except in those places where it is impossible to use another method.

The equipment of the roof heating system can be divided into the following stages:

- Design of system elements and their coordination;

- Implementation of the distribution network;

- Distribution cabinet installation;

- Installation of heating cables and sensors on the roof itself;

- Installation of equipment for control and switching;

- Testing and turning on the system.

Every year, when the autumn/winter season begins, a trial run of the system should be performed to check the overall performance of the anti-icing system.

In autumn and spring, as well as during thaws, icicles and frost often form on the roofs, which can harm not only the roof itself, but also the people under it.

To prevent their formation, it is recommended to perform roof heating using anti-icing systems and heating cables described in this article.

Did the article help you?