In individual housing construction, when constructing a roof, almost all homeowners choose a pitched roof shape, which is practical and cost-effective. Such a roof needs a reliable supporting system, and its basis is a rafter. Not a single roof that has any significant slope (from 5% or more) can do without this element. And together they form a truss system, which perceives all the loads falling on the roofing. How rafters are arranged and calculated - later in the article

In individual housing construction, when constructing a roof, almost all homeowners choose a pitched roof shape, which is practical and cost-effective. Such a roof needs a reliable supporting system, and its basis is a rafter. Not a single roof that has any significant slope (from 5% or more) can do without this element. And together they form a truss system, which perceives all the loads falling on the roofing. How rafters are arranged and calculated - later in the article

If we compare the roof of a building with the human body, then the roof supporting structure in it performs the function of a spine, and each of the rafters, respectively, is a rib.

Requirements to roofing material the following are presented:

- The tree must be dry - no more than 2% moisture

- Grade of wood:

- For puffs in hanging rafters - not lower than 1st grade

- For rafter legs - 1-2 grade

- For racks and struts - 3rd grade with a minimum of knots

- Strength - the planned load should take into account the weight of the roof and the snow carpet on it (for most of Russia - 200 kg / m2). The total mass is divided by the planned number of rafters

- Resistance to atmospheric and biological influences

Important information! Often only inclined beams connecting the wall and the ridge (with or without a ridge beam) are mistakenly called rafters.

However, this beam is actually a rafter leg, and a rafter should be called the entire structure that makes up one section of the system in a cross section:

-

- rafter legs

- struts (struts abutting against the supporting structure of the building or rack)

- racks (vertical supports supporting rafter legs)

- crossbar (horizontal beams installed between the rafters parallel to the ground)

- for hanging rafters - headstock (vertical rack working in tension)

- screeds (horizontal elements that prevent the walls from bursting with rafter legs), in some cases - other elements.

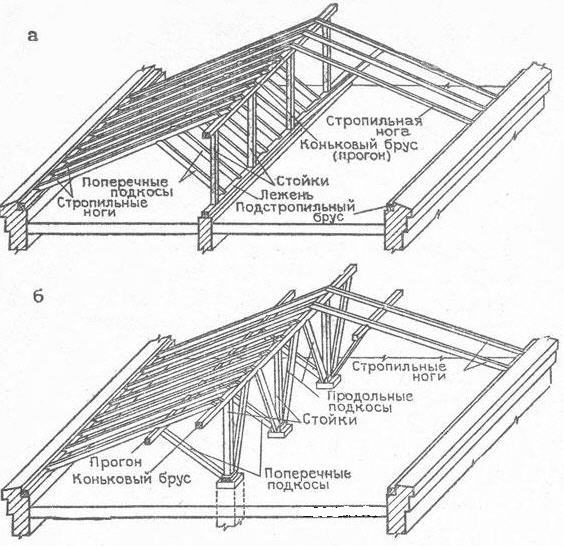

Roof truss system performed according to three schemes: layered, hanging and combined. In cases of large spans, roof trusses are also created, made either on the basis of hanging or layered structures, or in the form of a combination of them.

The device of layered rafters: knots and connections

Laminated rafters are called so because they rely on external load-bearing walls (directly by the side of the rafter leg) and internal load-bearing structures (if any) - walls or columns through a system of racks. With a span (distance between the outer walls) of up to 6 m, the racks may not be arranged, especially if there is nothing to support them with.

In the center, in any case, the correct installation of the rafters involves the installation of a ridge beam, on which the opposite legs of one rafter converge. Along the perimeter of the building, a rafter beam - Mauerlat - is laid on top of the walls.

In wooden log cabins, its role is played by the last crown. In order to save money, you can not make a solid beam, but put trimmings (necessarily of the same section) under each leg.

Mauerlat is fastened with pins or bolts to the reinforcing concrete belt or the top of the wall (vertically, to a depth of 40 cm), or - on wire ties (φ>= 6 mm) no higher than 3 rows of masonry from the top (the screed should be laid when erecting the wall ).

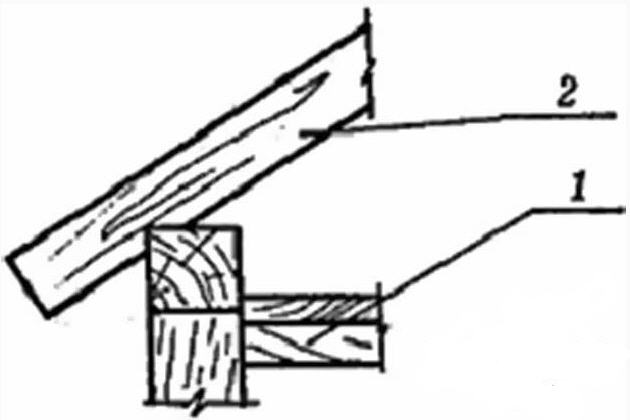

In the rafter leg, at the place of its installation on the Mauerlat, a selection of the appropriate shape and size is made, which is placed on the rafter beam. Additionally, the assembly is fastened with bolts, metal plates, or brackets.

Important information! For new buildings, especially from logs and timber, the final shrinkage of which has not yet been completed, a system of floating or sliding rafters is installed. The fastening of the leg is not rigid, but with the help of a plate with slots through which the self-tapping screw or bolt screwed into the leg has free play. On the ridge beam, the rafters are also hinged.Due to this, during shrinkage, the rafters do not break, do not bend, but take on a new shape corresponding to the changed configuration of the load-bearing walls.

Hanging rafter scheme

The hanging system is structurally different from the layered one, respectively, in this case, the installation technology of the rafters will be different.

At one or another height, the rafter legs are connected by a puff, respectively, the only force that is transmitted to the wall is the vertical pressure of the roof.

We can assume that in this case, the rafters before binding with ridge and rafter beams are a completely autonomous system. In this case, the support of the rafter legs or puffs can be carried out both on the Mauerlat and directly on the load-bearing wall.

With a span width of up to 6 m in hanging rafters, the floor beam can play the role of tightening. With large span sizes, headstocks, crossbars and slopes are additionally mounted.

To connect the headstock and the puff, a bracket is used, passed under the bottom of the puff, for the remaining nodes - the same fastening methods as for the layered rafters.

Assembly of roof structures

Of course, the device of the video truss system will show the best way, and this process looks like this.

If you do not assemble, then it is necessary to mark the truss structures on the ground - this is both more convenient and safer. It is possible to immediately fit all the necessary elements to one size.

ADVICE! When pre-cutting the details of the rafters, it is better to leave a small margin in length so that, if necessary, you can adjust the dimensions of the structure in place.

- To mark the rafter legs, a piece of timber or even round timber of small diameter is taken (the latter is hemmed in the middle), the length of which is equal to the distance between the walls of the building. In its center, a bar is perpendicularly stuffed, the length of which is equal to the height from the level of the rafters resting on the wall to the ridge. Further, each of the rafter legs is placed at an angle between the edge of the longitudinal beam and the top of the transverse bar.

At the top point, a mark is made with a construction pencil, on the basis of which the place of cutting will then be taken. In a system with hanging rafters, puffs are measured in a similar way (based on a horizontal bar).

If the structure of the rafter is quite complex - with supports, headstocks, struts - for the time of marking, the structure can be grabbed with small carnations using thin rails.

- When all the rafters are measured and marked, and possibly even cut and assembled, they are raised to the roof. Assembly on the ground implies greater convenience, but not always the strength of the structure allows it to be subjected to the loads that arise during the lifting process. Regardless of where the parts were assembled, the instruction recommends installing the truss system in that order. First, extreme rafters are installed at both ends of the roof. Now it is still impossible to fix them completely, since it is necessary to determine the symmetry. To simplify the process roof rafters they can be temporarily connected to the Mauerlat with temporary fasteners.

- Next, the slopes of the future roof are measured. To do this, connect the top of each rafter with a twine to the lower corner of the opposite - first on one side, then on the other. In this case, the strings for each of the slopes should cross exactly in the middle of the roof, and only slightly touch each other.If the geometry turned out to be different, it is necessary to correct the location or the very design of the rafters until the desired result is achieved.

- For a better understanding of the procedure, you can watch a video with a visual demonstration of the entire progress of work before making the rafters. When the extreme rafters are exposed, their tops are also connected with twine along the line where the ridge beam will later pass. It is along this line that all the remaining rafters should be placed in the future. It is also better to put them on temporary mounts before setting up the entire system, since adjustments may be required. During installation, if there are doubts about the accuracy of the location of the structures, it makes sense to measure the slopes one or more times in the manner described above.

- After all the rafters are exposed, they are finally attached to the mauerlat or walls, and tied with a ridge beam passed under the tops of the rafter joints. After that, a crate is stuffed on the outside. If at some nodes the rafter does not rest on a tree, but, for example, on a wall masonry, waterproofing must be placed under it in the form of two layers of roofing material. The same applies to Mauerlat, struts and other wooden elements.

Did the article help you?