Everyone knows that the roof is the element that most decorates the house, gives it personality and testifies to the taste that the owner of the house has. If you decide that you need a do-it-yourself roof rafter system, then it is worth noting that there is nothing complicated in its construction.

Everyone knows that the roof is the element that most decorates the house, gives it personality and testifies to the taste that the owner of the house has. If you decide that you need a do-it-yourself roof rafter system, then it is worth noting that there is nothing complicated in its construction.

The only thing that needs to be clearly understood is that the roof - the truss system - is primarily an engineering structure that protects the building from environmental influences.

Depending on how well the installation is carried out, the reliability and durability of the roof structure depends - truss systems play an important role in this.

The main task of the skeleton is to withstand the entire weight of the roof and provide reliable protection from snow and wind. That is why, when calculating the roof truss system, it is very important to take into account the type of roof and the features of the area in which the house is being built.

In addition, you need to take into account also the margin of safety. It is impossible to proceed with the installation of the roof without taking into account this indicator.

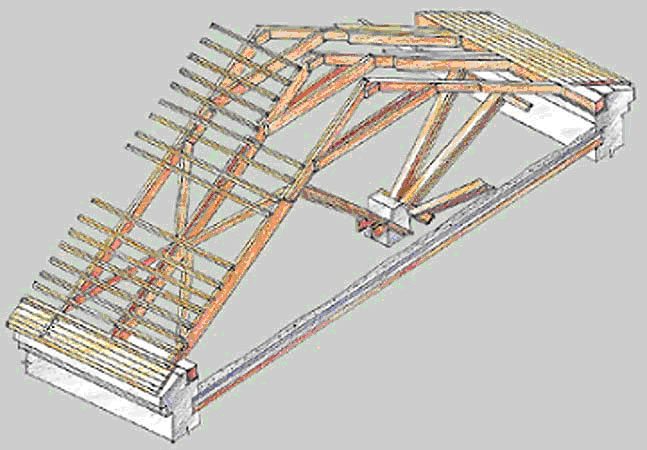

The necessary rigidity of the truss system is achieved by fastening the rafters to each other, as well as by fastening the box of the house and the roof frame.

Most often, roof rafters are made of wood.

Which is not surprising, since this material has many advantages:

- It's just being made.

- Easy to install.

- You can adjust the rafters made of wood at the installation site.

It is these factors that determine the use of wood, since rafters made of metal or reinforced concrete do not differ in the listed advantages.

Recently, bolts, self-tapping screws, nails, staples and clamps have been used to fasten rafters to each other.

Your attention! It is worth noting that fastenings made with nails are not strong and reliable. This happens due to the fact that the wood dries out after a while, which causes loosening of the truss structure.

It is not yet advisable to use bolted joints, since it is necessary to make holes under them, which greatly reduce the strength and stability of the structure as a whole.

That is why clamps and staples are used to connect the rafters. In addition, it is possible to make a rafter skeleton in industrial conditions.

This is achieved with the help of modern developments, with the help of which the entire structure is fastened in production with reliable connecting materials, which are the fastening strips.

Roof types

Before you make a roof truss system, you need to find out what kind of roofs exist in general.

In the modern concept, the roof is represented by a very complex system of beam ceilings and rafters, which are responsible not only for what shape the roof will have, but also for the functions by which it will be operated in the future.

Now the simplest and cheapest is gable standard roof, or oblique, as it is also called. An elementary example of pitched roofs is a pitched roof.

Such a roof is characterized by such a feature as the support of the roof on two walls of different heights. Most often, such roofs are built in commercial and industrial buildings, and it is not difficult to make it yourself.

The gable roof is popular. Its peculiarity is that two slopes converge at one point.

The most common roof of this option is the multi-gable roof. It can be used even in cases where a roof is conceived - the rafter part of which is represented by a complex structure.

Usage hip roof truss system gives the house an interesting design and gives the architect free rein for his imagination.

True, having given preference to such a design, it will not work to make it on your own, since it has many fractures and bends, therefore, in order to mount it, it is better to contact a highly qualified roofer, since only he can correctly calculate the roof rafters.

Also, the reason lies in the fact that with improper installation due to the large number of joints and bends, the load on the main elements may increase.

The reason for this is a large accumulation of snow, dirt or water, which can cause the roof to sag or leak.

The roof, which is similar to the Egyptian pyramids, is called hipped roof. You can make such a roof only if you have a square house, well, or in the form of a regular polygon.

The elements of such a roof suggest the convergence of isosceles triangles at one point. At the same time, it is important to observe the symmetry of the roof, since the whole charm of such a building will depend on it.

For many years, hip roofs have been used - the rafter system of which is presented in such a way that two slopes are formed from the ends in the form of a triangle and two in the form of trapezoids. It was they who received the name of the hips.

A common type of roof is the mansard view. Such a roof consists of four slopes, the top two of which are gentle, and the bottom two are steep.

During installation, roof rafters are arranged, designed to keep the usable attic space to the maximum. Usually such a roof is arranged if the owner is going to make space under the attic for living.

Installation

Installation of the roof truss system must begin with leveling the surface of the load-bearing walls with a screed. Waterproofing should be laid on the screed, and then the Mauerlat and the bed.

Next, the under-rafter support structure is assembled from girders, racks and struts.In this case, the extreme rafters for the roof are first installed, and only then the intermediate ones.

What will be the distance between the trusses depends on the design of the truss system and the bearing capacity of the crate. If a roofing cake is used for the roof, then it includes:

- Vapor barrier layer.

- Thermal insulation layer.

- waterproofing layer.

- Roofing material.

To your attention! In order to ensure a long service life of a wooden structure, ventilation must be done. This can be done by installing ridge and cornice vents, as well as roof windows. For roofs that are covered with piece material, the use of special tiles with holes is provided.

The device of the roof - the rafters of which are made at the construction site, require a lot of labor. The space between the ceiling and the roofing must be filled with a waterproofing insulation.

In this case, it is necessary to provide a gap for ventilation. The roof with the structure and material has a rigid relationship.

And the slope and shape of the roof can shorten the list of materials that can be used for roofing. In turn, the chosen coating dictates the way in which the installation will be carried out, how long it will last and when repairs are required.

Currently, in the construction markets, you can find many imported and domestic materials made of metal, ceramics, natural and polymer.

In order to make the right decision, you need to take into account the properties of the materials that claim your attention, carefully weighing all the pros and cons.

The choice of roofing material should be based on the principle of coordinating the service life of all components.

The main indicator when choosing a material is not its cost per unit area, but the price for the entire roofing system with the required performance and service life.

Also, the durability and reliability of the roof largely depends on the work performed: if the installation is done correctly, the roofing system will serve its owner for a very long time and it will need repairs in many years.

Did the article help you?