The roof is one of the most important components of any building (including residential buildings). In our article, we will talk about an inexpensive and reliable way to protect your own home from adverse weather conditions, which, moreover, does not require constant maintenance - this is the installation of corrugated roofing. Moreover, corrugated board will allow you to realize any design idea - there are no restrictions in choosing the shape and design of the roof.

The roof is one of the most important components of any building (including residential buildings). In our article, we will talk about an inexpensive and reliable way to protect your own home from adverse weather conditions, which, moreover, does not require constant maintenance - this is the installation of corrugated roofing. Moreover, corrugated board will allow you to realize any design idea - there are no restrictions in choosing the shape and design of the roof.

Profile sheet is the simplest, most practical and most common roofing material. The construction market currently offers corrugated board of various versions (by color, shape, wave pitch, etc.) of domestic and foreign manufacturers.

Therefore, there is plenty to choose from.

Roof decking is galvanized profiled steel sheets with or without a polymer coating.

The main distinguishing characteristic of corrugated board is the presence of a profile of different geometric shapes and heights, which gives the material the necessary transverse rigidity.

A special advantage of corrugated board is its low weight, so that its sheets can be laid on a lightweight truss system.

And this means that you can significantly save on the construction of the entire roof as a whole. Therefore, a roof made of galvanized corrugated board is by far the most economical option.

And not only in individual construction, but also in industrial construction too.

Modern innovative production methods make it possible to produce a technological process for coating corrugated board with colored polymers, which provides a new level of material protection against corrosion.

And this, in turn, increases the duration of the operational period of the corrugated board and, accordingly, the roof from it.

A roof made of corrugated board will last at least more than one decade without requiring constant maintenance.

You will not need to repaint it, as the polymer coating does not fade from ultraviolet rays and does not change its appearance even after many years of operation.

Advantages of corrugated roofing:

- roofing can be installed all year round;

- sheets of material are cut very easily;

- material waste is minimal;

- ease of installation (even a non-professional can do it).

When buying corrugated board, the buyer should not forget that each manufacturer produces an illustrated step-by-step instruction for roofing technology - be sure to ask the sellers for it.

Covering the roof with corrugated board does not present any particular difficulties. Before work, you must first study the instructions and listen to the advice of specialists.

They will tell you what rules you need to follow when working with pro flooring. It is not superfluous to find out the features of working with this roofing material.

Particular vigilance must be paid to the correct laying of sheets, and it directly depends on the slope of the roof.

Basic rules for laying corrugated board:

- If the slope of the roof is less than 14°, then it is necessary to make a horizontal overlap of neighboring sheets of at least 200 mm.

- If the roof slope is from 15° to 30°, then the sheets must be overlapped by 150 to 200 mm.

- If the roof slope is 30 ° or more, then it is quite acceptable to overlap the sheets by 100-150 mm.

- If the roof slope is 12° or less, be sure to seal all seams and overlaps (both horizontal and vertical) with a special silicone sealant.

Often, the repair and reconstruction of an old roof made of, for example, traditional slate, causes many problems for the owner of the house.

With the advent of such material as corrugated board, the task has become much simpler: the design of the lathing and the roof truss system does not need to be further strengthened, since corrugated board sheets are light in weight and will not increase the load on the existing roof.

Roof decking is fastened to wooden structures using special roofing screws. Modern hardware stores offer a wide selection of self-tapping screws from different manufacturers.

Distinctive feature of roofing screws:

- at the end they have a drill;

- have a special neon lining.

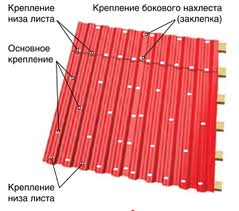

Important: the corrugated board is attached to the wooden structure only at the bottom of the wave. Usually, self-tapping screws with dimensions of 4.8x35 mm are used for fastening. In order to attach the skate, you will need longer self-tapping screws - 80 mm.

How to choose the right frame size?

As a rule, the size of the crate depends on the slope of the roof and the height of the profile of the profiled sheet used:

- If the angle of inclination of the roof is less than 15°, with the use of corrugated board grade PK20, the crate must be made continuous, with an overlap of the corrugated board in two waves.

- If you use the grade of H44 or more corrugated board, then the crate can be done in increments of 500 mm.

- With a roof slope of more than 15 °, the crate pitch should be from 350 to 500 mm (its width depends on which wave on the corrugated board).

Roofing with corrugated board has some more features that are important to know.

Installation rules

Roof slope

Under normal conditions, the recommended roof slope is not less than 1:7 (80°). When installing such a roof, pay special attention to ensuring proper ventilation, and also do not forget to seal through joints and leads.

Roofs with even steeper slopes require special design solutions.

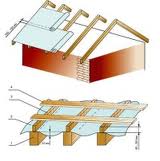

Lining

With normal ventilation, it is not necessary to lay a lining under the roof slabs. If in doubt, it is better to play it safe and put a lining.

For its arrangement, you can use a superdiffusion membrane. The lining will not allow the accumulation and penetration of condensate into the heat-insulating top layer.

For ventilation, a small space must be left between the first board of the crate and the gasket - 50 mm is enough. They begin to fasten the lining towards the ridge from the overhang. The edges of the lining must be wrapped up and nailed to the end board.

Ventilation

Under the roof of any house, moisture always condenses, which is released from all structural parts and premises of the building. In order to prevent condensation, it is necessary to carefully perform thermal insulation, vapor barrier and ventilation of the roof.

At the highest point of the roof, it is necessary to place holes for ventilation, be sure to equip additional ventilation ducts in hardly ventilated structures.

overlap

Roofs made of corrugated board will only perform their main function when the overlap is correctly performed. Usually, the side overlap should be done on half of the profile wave.

If the roofs are flatter, then the overlap should be even wider and it is imperative to use sealing tape or mastic to additionally seal the joints and overlaps.

In the deflection of each wave, the place of extension is attached to the wooden crate with the help of special screws for the roof. The installation of corrugated boards must begin from the end of the roof, and the corrugated boards are laid perpendicularly.

Important: if the corrugated board has a drain groove, then it must be laid with a lateral overlap (the groove of the top sheet must overlap the groove of the bottom sheet).

End plate

The end plank is laid with an overlap of 50 mm or more. It is attached to the plate with rivets or screws.

Attention: the end plate must cover the entire first wave of corrugated board. Moreover, its fastening pitch should not be less than 300 mm.

Snowplow

In order to prevent slipping and rolling of snow, you need to install a snowplow near the eaves. In those places where it will be attached to the eaves, it is necessary to further strengthen the crests of the waves of the corrugated board.

Cornice and ridge plank

The corrugated roof, like other roofs, has a cornice and roofing strips in its design. They are also fastened with special screws.

So, the ridge strip must be fixed with an overlap of 100 mm even before you fix the roof slabs. The ridge plank is overlapped (100 mm) in 300 mm increments and fastened with special rivets or screws.

If you are not confident in your own abilities, then it is better to contact a specialized company that performs roof decking installation at a professional level. Be sure to require a license to carry out such work, then there will be someone to ask in case of unforeseen complications.

Did the article help you?