Do-it-yourself installation of roofing corrugated board allows, with minimal financial costs and in a fairly short time, to get a roof that will not only look acceptable, but also provide effective protection from precipitation. Relatively small weight, mechanical strength and corrosion resistance of corrugated sheets make them quite versatile.

So we just have to carefully study the technology and apply it in practice with sufficient skill.In this article, I will reveal the main aspects of roofing using this material, starting from how the crate is made for corrugated board and ending with the installation technology of a metal profiled sheet.

What do we need to work?

materials

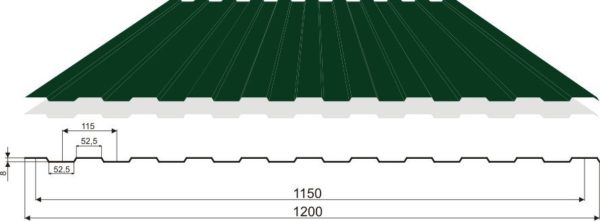

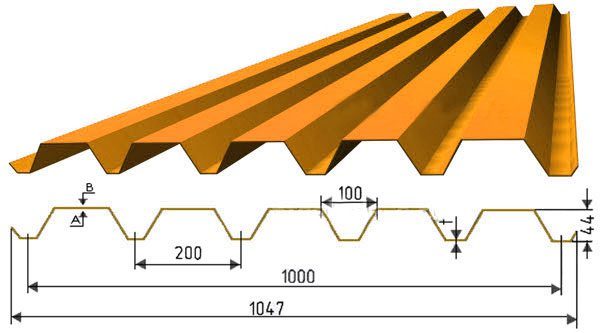

Naturally, the first issue that needs to be paid attention to is the selection of the roofing material itself. For the device of the roof, a variety of brands of profiled sheet are suitable, ranging from C8 - C21 to C44 or H60.

Naturally, for the construction of the roof of a small house, it is better to take a light material with a thickness of 0.5 - 0.7 mm with a relatively small corrugation height, while for industrial facilities it is desirable to use the most massive models available.

In addition to the profile sheet, we need:

- additional elements made of profiled metal - valleys, skates, corner, end and cornice strips, linings for adjoining walls, etc.;

- wooden bars and boards with a section of 30x100 mm for a sparse crate;

- plywood or oriented strand board with a thickness of 15 mm or more - for a continuous crate;

- waterproofing membrane;

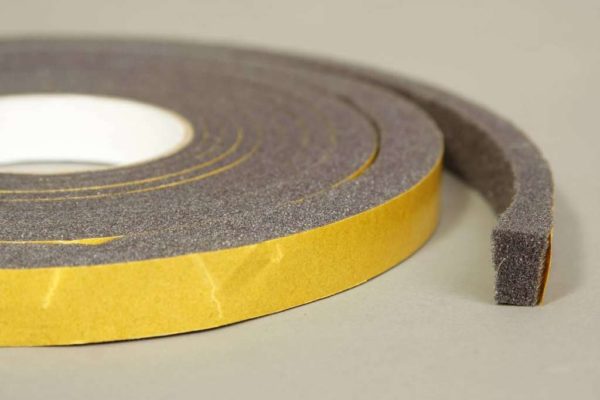

- sealing tape (both universal and special, with protrusions for corrugated board);

- self-tapping screws for assembling the crate;

- special self-tapping screws for corrugated board.

In addition, it must be borne in mind that corrugated board has a high thermal conductivity. Therefore, when using this material for roofing, it will be highly desirable to insulate it.

As a heat insulator, I prefer to take special roofing panels based on mineral fiber - although they are quite expensive, they perfectly retain thermal energy indoors.

Tools

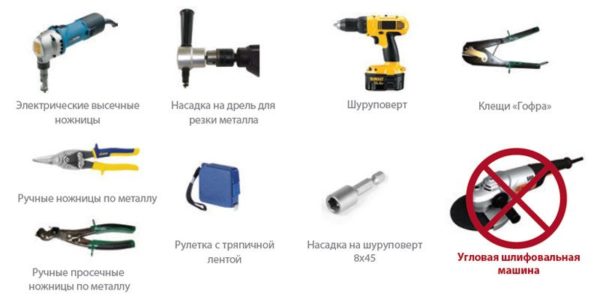

Self-assembly of a metal roof involves the use of a specially selected set of tools.

My toolkit includes:

- electric nibblers;

- nozzle for a drill for cutting metal;

- manual shears for metal for precise cutting and the formation of small notches;

Keep in mind that it is impossible to cut a profiled metal sheet with a grinder - when the disk rotates, the metal heats up very much, which leads to the destruction of the protective coating both on the outside and on the inside of the profiled sheet. As a result, when in contact with atmospheric moisture, corrosion develops in areas where pruning was carried out.

- a saw for wood to work with the details of the crate;

- construction stapler;

- knife for cutting hydro- and heat-insulating material;

- a screwdriver with a nozzle for the head of a "corrugated" self-tapping screw;

- a set of measuring tools - a long level, tape measure, plumb line;

- hand tools - several hammers, pliers, chisels, etc.

I also remind you that when roofing, it is advisable to protect yourself by using insurance to move around the roof.

The tool is best worn in the pockets of a special belt - so the likelihood that it will fall and become unusable (or cause injury to a person passing below) will be minimal.

roof base

A few words about thermal and waterproofing

As I noted above, despite a number of objective advantages, corrugated board also has disadvantages - in particular, its heat and sound insulation characteristics are purely symbolic.

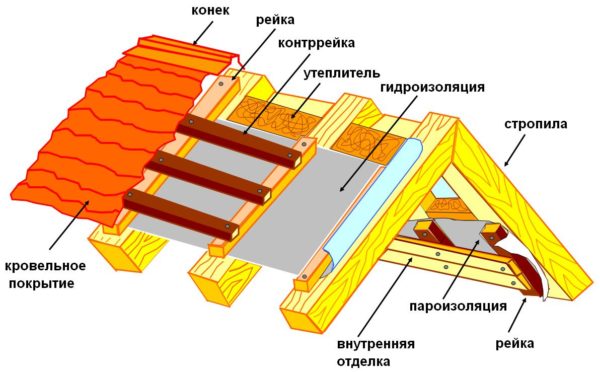

That is why, when constructing a roof from a profiled metal sheet, it is additionally insulated:

- In the gap between the rafters, panels of heat-insulating material - mineral wool or an analogue - are laid from the inside. The thermal insulation power is determined by the design thermal performance, but at least 75 mm should be laid under the corrugated board.

- From the inside, the mineral wool is covered with a vapor barrier membrane and fixed with transverse bars - a counter-lattice. These bars not only fix the insulation in the space between the rafters, but also provide a ventilation gap.

- The lining of the under-roof space is mounted on the counter-lattice: it can be made of lining, plywood, OSB, moisture-resistant drywall, etc.

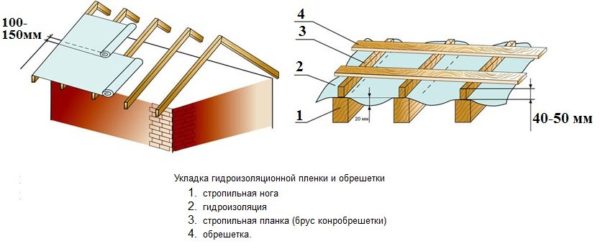

- From the outside, we lay a waterproofing membrane on the rafters (highly desirable - vapor-permeable).We roll out the membrane horizontally, moving from the ridge to the eaves, with a mandatory overlap. With a roof slope of 30 degrees or more, the minimum overlap is 100-150 mm, with a slope of 12 to 30 degrees - 250 mm. The membrane is fixed using galvanized steel staples or special nails with wide heads.

For a more reliable connection, I glue the joints of the waterproofing sheets with adhesive tape, which prevents water from flowing.

Calculation of the main parameters of the base

The next important element of the roof is the crate. The bearing capacity of a profiled sheet (especially high-profile models) is quite high, but still, the exact calculation of the crate for corrugated board is very important.

The type of foundation and the pitch of the supporting elements determine the rigidity of the coating, and if the design is not chosen correctly, there is a risk that the roof will “play”, bending under wind load and its own weight. As a result, the tightness will be violated primarily at the attachment points - and from here it is not far from leaks.

It is best to choose the optimal step of the crate for corrugated board according to the table below:

| Type of corrugated board | Thickness, mm | Roof pitch, degrees | Lathing pitch, mm |

| C - 8 | 0,5 | 15 and over | solid |

| C - 10 | 0,5 | up to 15 | solid |

| 15 and over | 300 | ||

| C - 20 | 0,5 – 0,7 | up to 15 | solid |

| 15 and over | 500 | ||

| C - 21 | 0,5 – 0,7 | up to 15 | 300 |

| 15 and over | 650 |

In the vast majority of cases, the crate is made of 30x100 mm boards or 50x50 mm beams. When installing a solid base, moisture-resistant plywood with a thickness of 15 mm or more or a material with a similar load-bearing capacity is used.

Based on the data obtained on the pitch of the corrugated board, we perform calculations: for example, if we need to finish the roof slope with dimensions of 3 x 5 m with a crate with a pitch of 500 mm, then we need at least 7 five-meter bars of the desired section.

In addition, do not forget about the removal of the roof (horizontal protrusion of the roof outside the gable) and overhang - a vertical protrusion outside the wall. So the final figure will be slightly higher.

It is worth initially finding out what length of lumber is available, and already making calculations for them. It is one thing if it is possible to order six-meter bars, and quite another if only three-meter panels are available, and willy-nilly they will have to be joined.

The stock of material for the crate should be at least 15 - 20%. This will allow us not to worry about trimming and fitting parts to size.

Lathing installation

The process of preparing for the installation of the crate is quite simple:

- For work, we select the material described in the previous section. The most commonly used boards and beams are made of pine, spruce, larch (in some regions this wood has the most affordable price), beech, etc.

- Before buying, be sure to check the quality of the material. It is advisable to build a crate of wood with a moisture content of not more than 18 - 20%. Large cracks, damage by wood borers, rot, through knots, etc. are also unacceptable.

It is not necessary to overpay and buy a jointed board / beam: the quality of the surface during the installation of the crate plays a secondary role.But you should pay attention to the geometry - the smoother the parts are, the less we will have to mess around, aligning them when installed on the roof.

- We treat all wooden parts with an indelible antiseptic. It’s not worth saving on antibacterial treatment: 90% of all roof repairs that I had to deal with were caused precisely by the failure of the crate as a result of rotting wood.

The design of the crate is quite simple:

- At the ends of the rafters we fill the rafter supports - bars with a section of 50x50 mm. They not only press the waterproofing material, but also form the air gap of the roof.

- Under the rafter supports, you can lay a special metal structure - a dropper. It is laid under the waterproofing material and serves to drain condensate. The dropper is attached directly to the rafters.

- We fasten the elements of the crate to the rafters perpendicularly, for installation using nails or self-tapping screws. We fasten the beam with one element in the center, the board with two: top and bottom. This approach allows you to compensate for the load, and the board, fixed at two points, will not go "propeller".

- Docking of parts is carried out only on the rafters. In this case, the end of each beam is nailed with a separate nail, after which the elements are “connected” with a bracket.

- When installing the base for the roof, we control the geometry of all the details: it is desirable that the boards lie perfectly flat, with a deviation from the horizontal of no more than 1-2 mm per 1 m. For control, it is convenient to use a stretched cord.

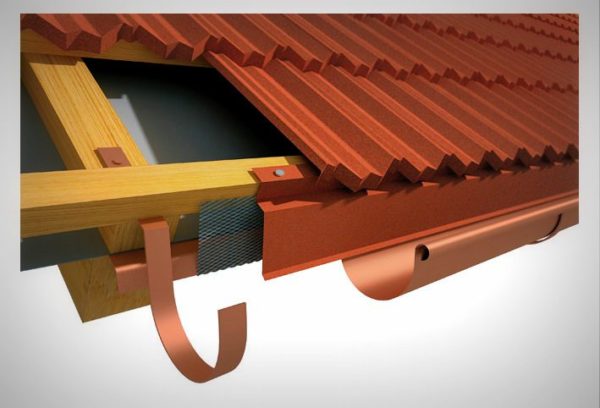

- In the lower part of the slope, along the eaves, we install the base board - it needs to be made thicker than the main parts. This board will be used as the base for the cornice plank.

- The cornice strip can be attached together with the gutter hooks.

- In the valleys, we install the lower valley strips, fixing them on the crate.

Roofing

Profiled sheet installation rules

Instructions for attaching profiled metal sheets to a crate made of boards, plywood or timber are given below. It is advisable to follow these recommendations as closely as possible, since it depends on how tight the roof will turn out.

The main factor determining the sequence of our actions will be the size of the material. The manufacturing technology of corrugated board allows you to make parts whose width is equal to the width of the roof, so that you do not have to join the sheets.

If we work with profiled sheets of a standard size, then the installation must be carried out according to the following algorithm:

- We start laying sheets from the bottom of the roof slope. As a rule, the lower left corner is chosen, since in this way we are able to optimally overlap the capillary grooves of adjacent sheets.

- We lay a sheet of roofing material on the crate, taking into account the gable ledge and cornice overhang, align and fix it with one self-tapping screw.

In this place, it is desirable to install a sealing tape that will block the space under the corrugations of the profiled sheet. The same tape can also be attached at the points of contact with vertical surfaces, along valleys, etc.

- Then we lay two or three more sheets horizontally, each of which is also fixed with one self-tapping screw - only so that they do not fall. When laying sheets, be sure to overlap the leftmost wave on the rightmost wave of the already installed part.

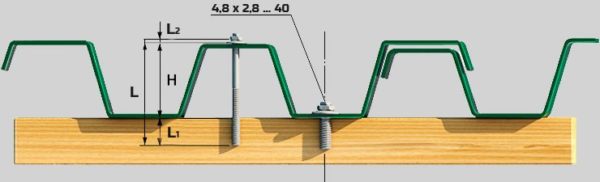

- Then we finally align all the details and proceed to fix them. For fastening, we use self-tapping screws with a drill, a hex head and neoprene washers-gaskets. When the fastener is tightened, the gasket self-vulcanizes, thereby ensuring tightness at the place of metal perforation.

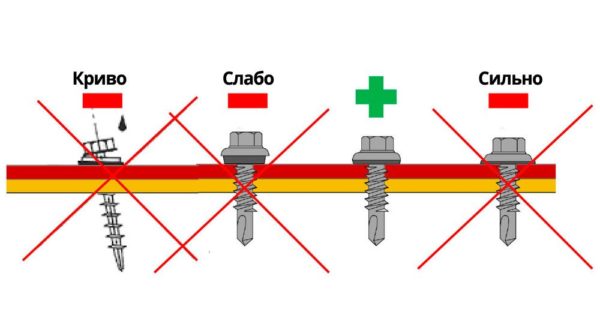

- We twist the self-tapping screws into the lower part of every second wave, along the sheet itself the fasteners are distributed in a checkerboard pattern (4 - 12 pieces per m2). At the same time, it is extremely important to control the tightening force: the cap should firmly press the elastic washer to the metal, but at the same time not bend it.

When working with sheets with a thickness of more than 0.5 mm, I prefer to carry out fastenings by pre-drilling (it is enough to “pass through” the metal and go a little deeper into the tree). At the same time, I choose a drill diameter slightly larger than the diameter of the self-tapping screw: the tightness does not suffer from this, but with the thermal expansion of the roof, much less stress occurs at the fixation point.

- The place of overlap is also fixed with self-tapping screws. It is advisable to use long fasteners that will reach the wooden base through the wave, but if this is not the case, you can limit yourself to the usual connection.

Sometimes it is advised to connect sheets with rivets, but this is such a laborious process that everyone is usually limited to self-tapping screws.

Junctions and other elements of the roof

After the slope is covered with corrugated board, we proceed to the installation of additional parts:

- Along the pediment, we install an end bar, which should cover one wave of the sheet located on the edge. The bar is attached to the board at the end of the crate, and to the corrugated board.

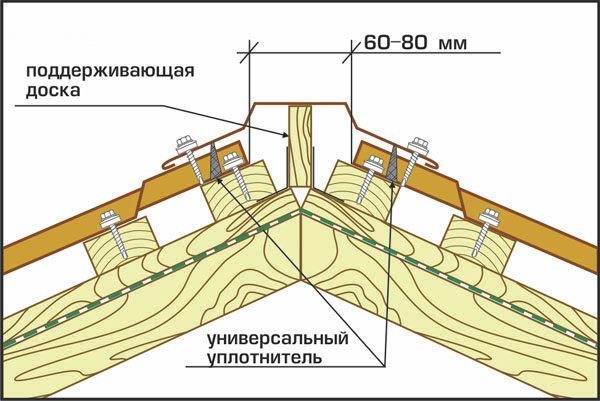

- We install a skate from above, which is supposed to go on both slopes. We rest the skate on a board mounted on an edge and fix it with self-tapping screws. To minimize heat loss, we lay a universal seal along the ridge.

- We put the upper valleys at the joints of the planes.

- We cover all the junctions of the profiled sheet with vertical surfaces with junction strips. At the point of contact between the plank and the profiled sheet, we lay a strip of sealing material. It is best to fasten the junction bar to the corrugated board with a long self-tapping screw - it reaches the crate and rigidly fixes the entire structure.

Conclusion

Knowing by what rules the crate is mounted under the profiled sheet and how the roofing material itself is attached to the base, you can independently cover the roof of almost any shape and area. Of course, it’s better to start with simple objects, especially since at first the video in this article will help you, as well as the tips that you can get by asking a question in the comments.

Did the article help you?