Do not know how to arrange eaves and gable overhangs to protect them from the weather and ensure ventilation of the structure? In this review, I will tell you how to choose and properly fix roof spotlights.

The working process

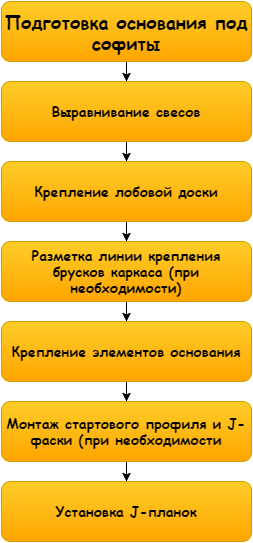

Now let's figure out what steps the workflow consists of:

- Measurements and settlement works;

- Acquisition of necessary materials and tools;

- Construction of the frame and fastening of the guides;

- Cutting and installing soffits.

Measurements and calculations

This is a pretty simple part of the job.

It consists of the following:

- To begin with, you must decide which surfaces will be sheathed with the material in question;

- Then you need to measure each part of the structure that will be hemmed. Record all dimensions on a piece of paper. Relying on memory is not worth it, you may miss some value or mix up the sizes, and then it will not be possible to carry out the calculations correctly;

- Next, you need to make an approximate sketch so that you can navigate the work and imagine where each of the parts of the structure is located. The figure indicates all hemmed areas;

- Based on all the data, you can make calculations of the required materials. If the width is more than 40 cm, then you need to fasten 3 bars along the entire length, if less than 40 cm, then two elements will suffice. The number of J-slats is calculated from the length of all surfaces, both outside and inside. That is, it is necessary to fasten the guides both from the side of the wall and from the outer part of the overhang;

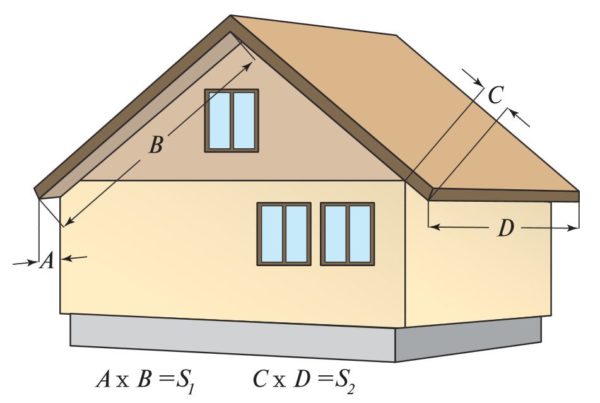

- Soffits are calculated by area, everything is very simple here. Below is a diagram according to which it will not be difficult to carry out settlement work.

If you have a roof of a complex configuration, then the easiest way is to calculate the area of \u200b\u200beach individual section, and then summarize the data.

Acquisition of necessary materials and tools

When you have all the data on hand, you can collect the necessary materials and tools.Often the developer has a question, what elements to use - plastic or metal? I will not compare these options, I will only say that vinyl products are much more durable than steel ones, and their price is several times less.

The list of materials is presented in the table.

| materials | Selection Guide |

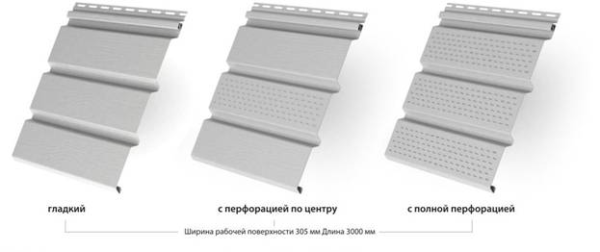

| Soffit | Types of spotlights are presented in the photo above, a specific solution is selected depending on the features of the structure. If it is necessary to ventilate the under-roof space, then it is better to take fully perforated spotlights. For filing overhangs, a smooth version is often used, and panels with perforation in the middle are universal and suitable for any designs. The cost of a product with a width of 305 mm and a length of 3 meters varies from 220 to 300 rubles |

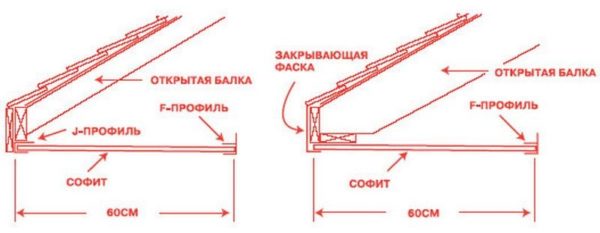

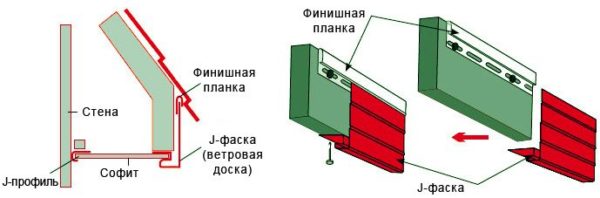

| Accessories | For installation, additional fasteners are used. A J-profile is used as guides (an F-profile can also be attached to the wall). If you need to close the end part as well, then you will additionally need a J-bevel and a finishing profile to fix it. To make it clearer, below is a wiring diagram of the two options. |

| Bars or slats | To fix the spotlights securely and evenly, you need to make a base under them. Most often, a pine bar with a moisture content of not more than 15% is used for this. If the width of the opening is up to 40 cm, then you can put elements only at the edges, but if the overhangs are larger, then it is better to add a vein in the middle |

| fasteners | To fix the finishing elements, we will use self-tapping screws with a press washer 25 mm long.To fix the bar to wooden surfaces, standard wood screws are used, and if you need to gain a foothold on a brick wall, you will need quick-mount dowels |

Now let's figure out what tool is needed to carry out the work:

- A hacksaw with a fine tooth is suitable for cutting both wood and soffit. If you have a jigsaw or electric saw, then you can use them;

- Screwdriver with nozzle PH2 for tightening self-tapping screws. If you need to fasten the bar to a brick or concrete wall, then a puncher with a drill of the required diameter is also needed;

- Level to control the plane, as well as a tape measure and a pencil for measuring and marking.

Assembly of the frame and fastening of the guides

In order to make it easier for you to navigate the work, the finished design is presented below. In fact, everything is very simple and clear, and this is the main plus of vinyl spotlights.

Do-it-yourself manual consists of the following steps:

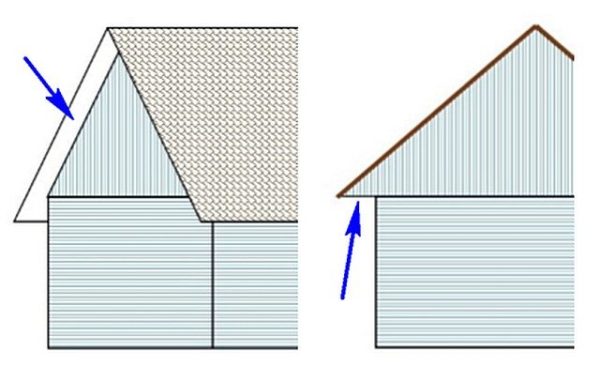

- First you need to straighten the line overhang. If you have boards sticking out on the gables, then cut them in one line. The same applies to the rafter legs on the overhangs, the ends should be located on the same line and at the same angle. Most often, these works are done during the construction of the roof, but sometimes it is necessary to eliminate the errors that remain;

- Then the front board is attached. It allows you to create a solid foundation and set the line for future filing.It is best to use polished elements, they are usually very smooth, and this is what we need. If the frontal board is already fixed, then this part of the work can be skipped;

If you have a crate with an extension, then in order to securely fix the frontal board and ensure its ideal position, you need to put spacers about a meter apart. With their help, the installation itself will be much easier.

- Using the level, a line is determined on the wall along which the frame bar will be attached. If you will hem the overhang along the rafters, then you do not need to mark anything. It should be checked whether all elements are located in the same plane. If there are deviations, then they must be compensated with the help of rails;

- Fastening the bars is very simple: they are located along the line and are firmly fixed on the surface with self-tapping screws or dowels. Usually, a wind board serves as the basis on one side, and a bar is attached on the other. It is important to set a flat plane here, since the appearance of the finished structure depends on this;

- If you need to sheathe the surface of the frontal board, then the starting profile is attached first. It is attached to the top line of the board. A J-chamfer is inserted into it and fixed on the underside of the overhang. Naturally, if necessary, the panel should be cut to the desired width before use, the assembly diagram is shown in the figure below in great detail;

- Planks are attached to wooden elements with self-tapping screws.Everything is very simple and fast here. If you have a chamfer on one side, then the guide is placed only against the wall. If only the lower part is hemmed, then the elements are located on both sides.

Try to fasten the guides at the same distance along the entire length, then it will be easy for you to cut the soffit and you will not have to adjust each element separately.

If you have protruding beams under the overhang, then you need to attach the starting profile to each of them so that the filing looks neat.

Fixing spotlights

If you have made the foundation according to all the recommendations, then fixing the vinyl spotlights is not difficult:

- First of all, the material is cut into pieces of the desired width. In this case, it is worth making the elements 5 mm less than the distance between the planks. The deformation gap will exclude damage to the skin during temperature changes;

- Work starts from the edge of the structure, the first element is inserted into the side grooves (it just needs to be bent a little). After that, it moves forward until the end enters the guide. From the other edge, self-tapping screws with a press washer are screwed into the holes;

- The next element is placed so that its protrusion engages with the previous panel. It is neatly located between the guides and snaps into place, after which it is fixed with self-tapping screws.;

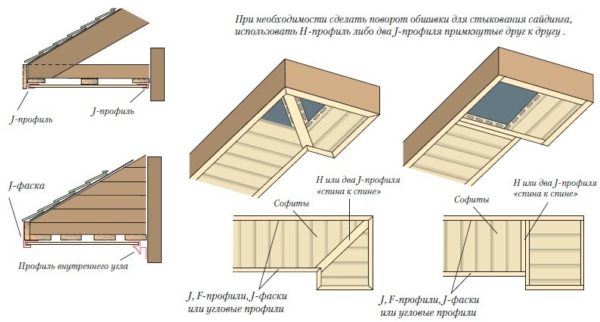

- Now let's figure out how to dock elements at the corners. Here you can choose either a diagonal option, when the connecting bar is attached at an angle, or a straight one. The second solution is easier to implement, the first looks more attractive, so choose the method that you like.Below is a detailed diagram that will tell you how to implement both options;

- The finished structure does not need special care, if necessary, the surface can be washed with water, nothing else is required.

Conclusion

Using this review as a guide, you can easily clad overhangs with vinyl soffits. The video in this article will tell you additional information on the topic, and if you have questions, then write them in the comments.

Did the article help you?