The cornice overhang is an element of the roof structure protruding beyond the walls of the building, designed to protect the house and the space adjacent to the foundations from atmospheric precipitation. This article will tell you how the roof eaves are made, what should be the optimal length of the protrusion and what types of cornice overhangs exist today.

The cornice overhang is an element of the roof structure protruding beyond the walls of the building, designed to protect the house and the space adjacent to the foundations from atmospheric precipitation. This article will tell you how the roof eaves are made, what should be the optimal length of the protrusion and what types of cornice overhangs exist today.

General information about the device cornices

In wooden houses, roof cornices are equipped by nailing or cutting in special profile brackets-templates along the perimeter of all four facades in the absence of an extension in the form of a courtyard from the northern facade.

Tarred or antiseptic-treated boards are attached to these brackets. The first nailed board, depending on the width of the strip of the cornice, can be 3-5 centimeters wider than the others, since it is essentially a replacement for the drip.

Decorative through carving can be used to decorate boards.

A simpler way of arranging the cornice is to sheathe the ends of the beams with a board, while if the rafters do not protrude beyond the boundaries of the walls, their length is increased by nailing pieces of the board to the ends of the beams.

It should also be borne in mind that when creating any cornice architectural profiles on brick walls, the thickness of the plaster must not exceed 50 millimeters.

Given this condition, if necessary, the solution is applied to one of the surfaces:

- Plank structures;

- Specially equipped masonry extensions;

- Mesh-covered metal frame.

To make the profiles of plaster cornices, profile board templates with double fittings are used, where the second fitting is used to pull the profile along the ground, after which it is removed and the first fitting is used to cover the clean profile.

If a roof eaves with a significant cross-section is being finished, then instead of a skid, rollers are used to facilitate the movement of a heavy template, while carefully monitoring compliance with the rules.

The eaves located in the incoming corners are profiled using special templates.

Useful: in order to ensure that the profile board of the template safely reaches the top of the corner, it should be positioned at an angle of 45 degrees relative to the wall.

A right-angled triangle, along the bisector of the right angle of which a profile board is attached, made from a pair of boards with preliminary chamfering from them, will be used as a slide for the template.

The base, made of a metal profile, is fixed between the boards so that the chamfers are facing outward.

To decorate various profiles of cornices, decorative plaster is used, the filler for which is granite and marble chips, quartz sand, crushed glass, mica, etc.

Three layers of plaster are usually applied:

- The first layer, called spray, is designed to adhere the plaster coating to the base, this layer is made using a mortar with a liquid consistency, and its thickness is selected from 5 to 9 mm in accordance with the base material.

- The second layer (soil) is made from a solution of a predetermined consistency according to the spray, which should already be set. The layer thickness is selected from 5 to 12 millimeters.

- The third layer, which is also the front one, is applied overlay, its thickness does not exceed 2 mm.

After applying the plaster, they begin stucco work, including profile rods directly from the eaves.

The main types of cornices

There are two main types of roof overhang:

- frontal, designed to protect the facade of the building and performed in the form of the edges of the roof slopes protruding beyond the boundaries of the gable wall, installed at an angle;

- lateral, made in the form of overhangs located on the sides of the building.

The width of the roof eaves directly depends on its location. For side overhangs, it is most often sufficient to release structures by 50-60 centimeters beyond the boundaries of the walls of the house, while for frontal overhangs, this distance can be increased to 1 meter.

The arrangement of the frontal overhang is carried out by releasing the ridge board at a predetermined distance beyond the boundaries of the facade, after which the load-bearing roofing beams fixed to the rafters are released in the same way.

Next, the cornice board is fastened to the end sides of the roof ridge and load-bearing beams. Hemming the lower part of the cornice frontal overhang is optional, although quite often it is still performed in order to improve the appearance of the building.

Important: to ensure the greatest reliability of the frontal cornice overhang, you should choose the same cross-sections of the horizontal beam and rafter structures.

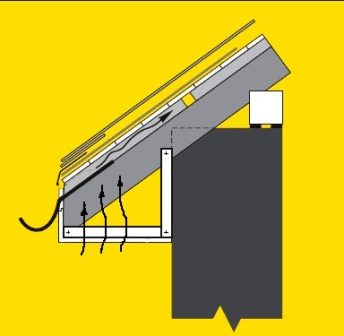

In the manufacture of the lateral eaves overhang, the roof beams are extended beyond the outer plane of the wall to a distance determined by the width of the foundation blind area and the height of the building under construction.

After the roofing material has been laid, the ends of the beams are fastened with a plank strapping, which will act as a cornice that hides the edge and the rough substrate of the roof deck.

The overhang space remaining open as a result is hemmed with a special material using a groove equipped in the lower part of the cornice board. Vinyl siding or tongue and groove boards are most commonly used for hemming.

These materials are attached to the house at 90 degree angles.

Eaves ventilation

Regardless of which type of overhang is chosen and what its dimensions are, ventilation is a prerequisite, especially if you plan to equip the attic in the attic.

The total area of the openings for ventilation should be in the range from 1/600 to 1/400 of the total area of the room for which ventilation is arranged.

In the filing of the cornice overhang, gaps are made to let fresh air into the interior, from where it is then removed through special openings in the roof ridge.

Important: Ventilation openings must be covered with mesh to prevent small birds or insects from entering the room.

The choice of material for the eaves

For sheathing cornice overhangs, a board of any length and width is most often used, the thickness of which must necessarily be from 17 to 22 millimeters.

Fastening of boards of small length can be carried out only at the ends, and for boards whose length exceeds 6 meters, fastening is carried out at each meter of their length.

The most suitable material is wood of various coniferous species (pine, spruce, larch, etc.). For the manufacture of boards, a dry material must be used that will not cause linear deformation of the boards after drying, leading to the appearance of gaps that spoil the appearance of the filing.

In addition to boards, sheathing of overhangs can be made with galvanized steel sheets, the thickness of which is 0.6-0.8 millimeters, as well as various perforated sheet materials, when using which the wavelength should not exceed 20 mm.

Important: working with such materials requires special skills and equipment, in addition, it is necessary to cover the processed fragments with a protective layer of paint after fitting.

Another material for filing overhangs is sheet aluminum coated with a protective layer of pollination, the width of which is selected in accordance with the parameters of the cornice overhang, the most common thickness is 0.6 mm.

In this case, the length of the sheets should be no more than 6 meters, since the sheathing is fastened with the help of special latches, as a result of which sheets of too long length may sag.

Useful: Specialty shops today also offer a wide range of decorative products to improve the appearance of eaves.

Sheathing of cornice overhangs

In winter, snow accumulates on the roof overhang, which can lead to the destruction of the overhang itself, and then the cornice and walls.

In the case of a minimum roof overhang, the absence or poor-quality manufacture of a cornice also causes the destruction of the masonry and the outer surfaces of the walls, which also causes first the rotting of the upper, then the lower logs of the crowns of the log house in wooden houses.

If the logs constantly get wet and dry, then they crack, the seams open and the caulk falls out, even the sheathing of the log house, covered with oil paint, can deteriorate if there is no waterproofing and poor chasing of the joints of the sheathing boards.

For these and many other reasons, for small (from 15 to 25 cm) roof overhangs, a cornice should be made that allows you to:

- Securely close the connection line of the upper part of the bearing wall and the internal structure of the roof slope;

- Give the facade of the house a finished look and provide additional protection for the surfaces of the walls of the house.

Did the article help you?