In modern construction, roofing sandwich panels are widely used - roofing panels have a design that allows for quick and easy installation in almost any weather. Aesthetically beautiful appearance, strength and thermal insulation characteristics, easy installation light weight. Due to their characteristics, sandwich panel roofing is carried out with lower costs and construction time.

In modern construction, roofing sandwich panels are widely used - roofing panels have a design that allows for quick and easy installation in almost any weather. Aesthetically beautiful appearance, strength and thermal insulation characteristics, easy installation light weight. Due to their characteristics, sandwich panel roofing is carried out with lower costs and construction time.

The strength ratings for these panels allow the use of lighter load-bearing structures. The width of the panels and the packaging methods are designed for convenient transportation of packages with panels.

The industry produces sandwich panels with various fillers:

- polyurethane foam,

- from polystyrene

- from mineral wool

- from polyisocyanurate.

Panels are produced with a large range of colors, including a range of metallic colors. Pay attention to long (up to 21 m) roofing sandwich panels - color characteristics may vary slightly in the longitudinal direction.

Advice. In this regard, it is necessary to install the panels in the same orientation from the same package. For an earlier evaluation of colors, remove the protective film immediately.

The minimum roof slope of sandwich panels is allowed to be more than 5%. This is for roofs that have solid panels, short pitches (no cross connection) and no skylights.

If there is a transverse connection, then a slope of more than 7% is allowed.

Features of transportation

The roof sandwich panel is produced by manufacturers for the construction of houses up to 21 m long. Naturally, specially equipped vehicles are required to transport such long parts.

Advice. In addition, the driver is required to obtain a written permit for the transportation of long vehicles.

Observe the following shipping requirements for panels.

- Under the ends of the panels protruding beyond the dimensions, it is necessary to place a special solid support.

- If the vehicle is with a trailer, its surface level must match the surface level of the main body.

- For trucking, a special two-level support is mounted, which increases the efficiency of transport loading. Packages covered with stainless steel are not allowed to be transported in this way.

- Every 100 km, the driver is obliged to check the reliability of the fasteners by visual inspection.If the fastening is loose and the load has shifted, it is necessary to tighten the fastening straps.

- The width of the belts is not less than 50 mm.

- Panels can be transported at speeds up to 70 km/h.

Accurate unloading

Before rigging, check the condition of the package, whether there are any damages, etc.

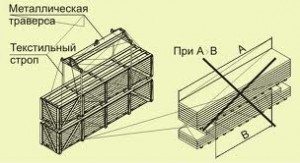

The package is lifted with a flat rope with eyes. The manufacturer indicates the hanging points with colored markers or crayons. When lifting, use wooden spacers that hold the straps at a distance wider than the width of the package.

Advice. For long packages, over 8 m long, a special cross beam 8 m long is used for lifting.

Warehousing and storage of packages

If roof sandwich panels are stored outdoors, protect them from precipitation, strong winds and dirt.

For long-term storage, the bags are covered with cloth covers, such as covers for cars. Synthetic film is not allowed.

Such fabric covers "breathe", which leads to the rapid drying of moisture under them. If the panels are not ventilated for a long time, they may be damaged, moisture must not accumulate in the space between the panels.

To avoid dents and imprints that spoil the appearance of the panels, observe the following storage rules.

- Do not store panels at the construction site.

- The storage base must be level and solid, and not lead to deformation of the panels.

- When storing on the roof, rely on load-bearing structures to avoid overloading the ceiling.

- It is forbidden to store panels on the roof.

Advice.Partially unpacked packages should also be protected from precipitation and strong winds.

Installation conditions

Roofing from sandwich panels requires strengthening the safe conduct of construction work.

So how cover the roof such material?

When working with long panels, observe additional mounting requirements.

- The wind speed should not be more than 9 m/s, due to the relatively low weight of the panels and their large area.

- Do not do it installation of roofing sandwich panelswhen it rains or snows, or there is thick fog.

- If darkness has come and there is no artificial lighting, installation should be stopped.

- The sealing of the longitudinal joints of the panels should be carried out at a temperature above 4°C.

Preparing for installation

Installation begins after the following preparatory activities.

- Check the design, care and consistency with the project, and correct any differences or problems.

- Check whether the girders, posts and beams comply with the design and guidelines for statistical loads.

- Check for flatness of mounting girders.

- Check the linearity of the pillars and crossbars in the walls of the facility in accordance with SNiP 3.03.01-87 "Bearing and enclosing structures".

- Check the execution of work in the basement of the building, and the completion of waterproofing work.

- Prepare the tool you will need to install the panels.

It is forbidden to carry out welding work during and after installation near the panels, as this may cause damage to the coating of the panels.

Adjustment of panels and sheet metal profiles during installation

To fit the sandwich panels, fine-toothed saws are used. If there is a stationary cutting machine, it is acceptable to use circular saws with an accurate guiding system.

Advice.Roofing sandwich panels may lose their presentation from sawdust. Remove sawdust immediately to avoid damaging the surface.

It is unacceptable to use grinders and abrasive tools for trimming. This may damage the anti-corrosion layer due to the strong heat of the cutting area and sparks.

Advice. Roofing sandwich panels in places where the cutting is made must be strengthened, since the cross section is reduced there.

Tin profiles are cut during installation with hand scissors for metal when finishing the roof.

In order not to spoil the appearance of the part, cut the parts on soft surfaces, such as felt.

Advice. Remove the protective film before installation, after installation of the part it will be much more difficult to do.

The article describes the features of transportation, preparation and installation of roofs from sandwich panels. The characteristics of the panels and safety requirements are highlighted.

Roof sandwich panels are the perfect solution: modern design, quick and easy installation.

Did the article help you?