Nowadays, it will not be difficult to find such material for mounting roofs as galvanized roofing iron. This is a universal material, it can be mounted on absolutely any surfaces of various buildings. You can’t do without it during finishing work, when repairing old roofs and with a simple arrangement of industrial facilities.

Nowadays, it will not be difficult to find such material for mounting roofs as galvanized roofing iron. This is a universal material, it can be mounted on absolutely any surfaces of various buildings. You can’t do without it during finishing work, when repairing old roofs and with a simple arrangement of industrial facilities.

galvanized roof

The popularity of roofing iron is explained by its practicality and long service life.

You can buy such iron quite inexpensively, and it will not be difficult to acquire it either: in any hardware store, you can choose galvanized roofing iron in the market.

Moreover, iron roofing can be found in various colors and shapes. All this allows designers and architects to show their imagination, experience and skill in the construction and decoration of buildings.

Many enterprises in our country are engaged in the production of roofing iron.

Several types of this material can be distinguished: sheet and flat rolled plates with small ribs, metal tiles, as well as corrugated board (coverings from profiled sheets).

In general, roofing iron is steel, coated on both sides with a layer of zinc that performs a protective function. The layer thickness ranges from 250 to 320 g/m2.

Recently, much attention has been paid not only to quality, practicality, but also to the attractive appearance of materials.

Therefore, roofing iron with a polymer coating appeared on the market. It has not only an attractive appearance, but also enhances the anti-corrosion properties of the material.

Keep in mind that in addition to the types of roofing iron described above, there are a number of other types of this material. So, if you know that the roof of the house will be constantly exposed to powerful solar radiation, then purchase material that is resistant to ultraviolet radiation.

And if there is no such need (you do not live in a too warm climate, you do not need to protect your home from the sun), then give preference to such roofing material that will actually benefit.

Perhaps you need protection from an aggressive environment or resistance to mechanical damage - therefore, look for just this type of roofing material, a variety of roofing iron will certainly meet your expectations.

The advantages of roofing iron include the fact that its sale is ubiquitous, it has a low price and requires a minimum of maintenance.

Moreover, it can be installed on roofs with absolutely any geometry, as well as when installing downpipes, wall gutters and cornices.

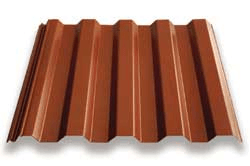

Decking

Let's talk a little about corrugated board. It represents the same iron sheet, the surface is galvanized, but the corrugated board is subjected to profiling, that is, it is given a wavy shape. This is done to increase the rigidity of the material.

Another name for corrugated board is corrugated roofing iron. It can also be made with or without a polymer coating.

When choosing roofing steel sheets in the store, on the market, you can give preference to sinus-shaped, trapezoidal, rounded shapes, choose a profile for various conditions of use.

And to expand the capabilities of architects and designers, create unique buildings, for the construction of roof ridges, it is possible to purchase roofing profiled transversely bent iron.

metal tile

The leader among the roofing is the all-sheet metal tile. It differs from the profiled galvanized sheet by a special polymer coating and transverse stamping, which allows you to imitate the pattern of a real tile.

This material looks perfect on small houses, temporary structures such as cafes, stopping points, kiosks.

But there are some negative points here.The fact is that when it comes time to repair a metal tile, it is imperative to purchase it only from the same manufacturer where it was originally bought!

Unfortunately, sheets from other manufacturing companies will definitely have different sizes, sheet shapes, and profile wave steps.

Despite the availability of roofing iron, its cost still differs depending on the characteristics of the material. But, as with the purchase of any material, it will be more profitable to buy roofing material in larger quantities.

The thickness of the roofing iron can also be different. Here are the main thicknesses produced by manufacturers: 0.4; 0.5; 0.7; 0.8; 0.9 and 1 mm. But recently, another 0.45 has been sold on the market; 0.65 and 0.75 mm.

Advice. Therefore, be careful, the difference in thickness is minimal, but for the construction of a house, a structure, you should purchase exactly the thickness of the roofing material that the technology requires. Be vigilant, try to avoid deception by scammers.

It will be impossible to distinguish the difference with the naked eye, the way out of this situation can be either testing the reference samples for strength, or using a special tool - a micrometer.

So, for example, if experts recommended that you purchase corrugated roofing iron, please, look for it in the markets.

Did the article help you?