In our time, the use of panels with fillers that combine several functions at the same time has gained great popularity: this is a roofing cake assembled in one panel. Installation of roofing sandwich panels is not very complicated. Fitting in place is allowed here, which gives enough flexibility to create complex roof shapes.

In our time, the use of panels with fillers that combine several functions at the same time has gained great popularity: this is a roofing cake assembled in one panel. Installation of roofing sandwich panels is not very complicated. Fitting in place is allowed here, which gives enough flexibility to create complex roof shapes.

Preparing for installation

Roofing sandwich panels can be profiled on both sides or only on the outside. (Footnote 1)

Installation requires preparation.

Check the design for compliance with the project, especially the following aspects:

- check the main dimensions and slope of the roof;

- check the compliance of the arrangement of poles and crossbars with the requirements in the tables of statistical load;

- check the accuracy of the run plane;

- check the perpendicularity of the pillars and crossbars in the walls;

- check the completion of work on the basement, and waterproofing;

- check the presence of the tool that will be needed when installing the panels.

Good preparation of the structure will make installation easy and guarantee reliable operation of the connections for fastening the panels.

Installation of roofing sandwich panels must be started after completion of all welding work must be carried out before installation, in order to avoid irreversible damage to the coating.

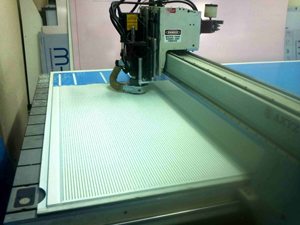

Fitting panels and profiles

At any construction site, adjustment of some details is inevitable. This also applies to sandwich panels.

Advice. Use saws with fine teeth, do not use grinders or abrasive tools. Overheating at the cutting point may damage the anti-corrosion coating.

Circular saws can be used on stationary machines with a precise cut-off system.

After cutting, immediately remove the chips to protect the surface of the panels from damage.

If the cutouts reduce the cross section, hardening is required.

Tin profiles are cut with scissors for metal.

More tips. For better preservation of surfaces, place felt or similar material. Do not cut material on the roof, on mechanical platforms, scaffolding, it is dangerous.

Remove the protective film immediately before installation.

Panel Mount Connectors

Roofing sandwich panels are fastened with recommended connectors.Corresponding connectors are available for different thicknesses and designs.

To properly fix the panels, carefully observe the perpendicularity of the drilling, use squares. The weak slope of roofing sandwich panels is easily misleading when drilling "by eye".

Advice. Since the length of the connectors is long, it is recommended to use screwdrivers with a special head for assembling long connectors.

The roof must provide not only protection from external influences, but also from the contents of the building. In this case, special stainless steel screws are used.

They are used in the following cases, if inside the building:

- high humidity;

- chemically aggressive environment;

- careful protection of content is required.

These connectors have a vulcanized layer to protect the holes. Upon assembly, complete sealing is immediately achieved. They use a special support thread that provides water tightness.

This gives protection in two places: both under the head of the connector and at the junction of the panel with the support.

Shades of color

Sandwich panel roofing is made from long pieces. Standards allow slight color variation along the length.

Therefore, the panels should be laid according to the orientation in the pack and checking the color numbers on the pack. Most of all, this applies to panels with a metallic color.

Advice. Checking the correctness of laying by color must be done from afar. Move 50 meters away from the building for visual control.

Roof slope

The minimum slope of a roof made of sandwich panels is as follows:

- more than 5% for roofswhere there is one panel on the slope, no skylights and no pieces;

- more than 7% for roofs if there are slope connections or skylights.

It is necessary to take into account the permissible loads on the supports for the roof.

Ways of lifting and laying panels

For laying large panels, a crane must be used.

Lifting panels requires the following rules.

- panels should be lifted one at a time.

- use carpenter's clamps with felt or rubber pads to grip the panels so as not to spoil the surface of the panels;

- when laying long panels of more than 8 m, use a traverse beam with a length of eight meters;

- every 3-4 m, the long panel is additionally suspended from the beam;

- consider roof pitchso as not to damage the edges of the panels when lowering to the installation site;

- before laying on the roof structure, remove the protective film from the bottom (inner) side;

- all workers on the roof must wear shoes with soft soles so as not to damage the coating of the panels;

- when laying, insert the next element close to the previous one, so that the protrusion falls into the cavity;

- for plates filled with mineral wool or expanded polystyrene, where a layer of sealant is applied on the inside of the lock for hydroprotection.

Advice. Do not use acidic silicone for sealing.

The more precisely the installation along the longitudinal axis is carried out, the better the gaskets for sealing will work.

Screwdrivers

When installing long connectors, screwdrivers equipped with special heads are needed to install such screws and adjust the depth of the bolt head.

Characteristics of recommended screwdrivers:

- power - 600-750 W;

- revolutions - 1500-2000 rpm;

- torque - 600-700 Ncm.

Installation of roof panels

Below is a table (Footnote 2) of the maximum panel length allowed for the lifting mechanism

| Installation of horizontal panels | Installation of vertical, diagonal and cutting panels | ||||

|---|---|---|---|---|---|

| Panel | Lifting tool and safety strap /Max. panel length | Lifting tool and safety strap /Max. panel length | Panel | Lifting tool and safety strap /Max. panel length | Lifting tool and safety strap /Max. panel length |

| SPA100 | 1 PC. / 6.5 m | 2 pcs. / 13.0 m | SPA100 | 1 PC. / 6.0 m | — |

| SPA125 | 1 PC. / 5.6 m | 2 pcs. / 11.2 m | SPA125 | 1 PC. / 6.0 m | — |

| SPA150 | 1 PC. / 5.0 m | 2 pcs. / 10.0 m | SPA150 | 1 PC. / 5.6 m | 2 pcs. / 6.0 m |

| SPA175 | 1 PC. / 4.6 m | 2 pcs. / 9.2 m | SPA175 | 1 PC. / 5.0 m | 2 pcs. / 6.0 m |

| SPA200 | 1 PC. / 4.2 m | 2 pcs. / 8.4 m | SPA200 | 1 PC. / 4.6 m | 2 pcs. / 6.0 m |

| SPA230 | 1 PC. / 3.7 m | 2 pcs. / 7.4 m | SPA230 | 1 PC. / 4.0 m | 2 pcs. / 6.0 m |

The installation procedure is described below:

- The fastening of the panel begins with fixing with one connector to the run, following under the ridge. Then the panels are attached to all other runs, except for the ridge.

- Panels from the edges of the roof are fastened with three self-tapping screws to the support run. The connectors screw into the top of the panel trapezoid, not into the gaps between the protrusions.

- The remaining panels are attached to the supporting girders with two self-tapping screws.

- For hot or cold rolled panels, different types of self-tapping connectors are used.

- To seal the panels at the joints, self-tapping screws of the third type with a pitch of 400 mm are used, they can be tightened with ordinary screwdrivers without nozzles.

- The exact number of fasteners must be specified in the project, it is determined by the calculation of the weight and wind load.

Mounting the skate

- At the end of the panels, an internal ridge bar is mounted on the slopes.

- Then all the gaps between the panels are filled with mounting foam.

- After it hardens and cuts off the excess, a polyurethane profile gasket is installed.

- For panels filled with mineral wool, the joints are filled with mineral wool and special seals.

- From above, a ridge bar is fastened with connectors to the ridges of the panels from both slopes.

- A self-adhesive polyurethane gasket is placed on top.

- Finally, the ridge bar is mounted on top with short connectors, thus building your roof finished.

Water diversion

There are several recommended options for installing a drainage system after assembling a roof from sandwich panels. Here is one of them:

- The panels in the overhang are finished with a special strip along the length of the overhang.

- Cut the insulation under the top skin. To do this, you need an electric drill with low revolutions up to 3000. The hole is made with a long twist drill 65 mm and a diameter of -5 mm. Make an incision across the panel.

- Fasten decorative strips to the paneling from above and below with reliable rivets.

- Attach hooks between the slats for fastening the gutters of the ebb.

- Apply sealing compound under the top bar.

- Install on the hooks of the gutter.

Advice.If a steel gutter is used for the catchment, use other special parts.

Common installation errors

From the experience of builders, analyzed by manufacturers, the following typical errors are known when installing a roof from panels.

- non-compliance with the requirements of manufacturers;

- replacement of recommended materials with analogues;

- lack of specialized tools and equipment;

- low qualification of installers.

The article discusses the technology of mounting a roof from sandwich panels, the necessary tools, the assembly procedure, the requirements for assembly quality and safety, typical builders' mistakes.

Did the article help you?