The metal profile for the roof is one of those materials whose popularity has recently been growing at an incredible pace, especially in the construction of private buildings and cottages. Due to their good technical performance, profiled sheets have a high bearing capacity, and due to the absence of joints along the entire length during installation, they provide excellent protection against precipitation.

The metal profile for the roof is one of those materials whose popularity has recently been growing at an incredible pace, especially in the construction of private buildings and cottages. Due to their good technical performance, profiled sheets have a high bearing capacity, and due to the absence of joints along the entire length during installation, they provide excellent protection against precipitation.

In addition, the advantage of the material is its low cost, as well as the fact that the roof of the metal profile is not afraid of corrosion, since the sheets are protected by a special polymer coating.

Preparing a metal profile for installation

The installation of a metal profile on the roof is quite simple, since the material is very practical, relatively light and not difficult to process.

Advice! To avoid damage to the sheets during transportation and unloading, they must be laid with cardboard and carried in a vertical position without kinks.

The roofing profiled sheet should be lifted onto the roof along the logs, which are installed from the roof to the ground, one sheet at a time.

To install a metal profile roof, you will need:

- screwdriver;

- self-tapping screws;

- electric scissors or a hacksaw for metal.

It is also necessary to decide on the type of metal profile most suitable for a particular case.

There are the following types of profiled roofing sheets:

- grade C profile with a wave height of 8 to 44 mm trapezoidal or sinusoidal; it is most often used when constructing protective structures, arranging a light roof, as well as when mounting on a wall for decorative purposes;

- NS brand profile, the wave height of which is 35 and 44 mm; usually applicable when installed on roofs, sometimes on walls.

- profile brand H (wave height 57-114 mm); has additional stiffening ribs and is applicable for solid roofing and floors.

Rules for laying a roof from a metal profile

To perform a competent installation, the roof profile must be laid taking into account the angle of the roof, since this indicator affects the amount of required overlap of adjacent sheets (rows of sheets):

- with a slope of 12-15 degrees, overlap of sheets of at least 20 cm is provided;

- with a slope of 15-30 degrees - the overlap should be from 15-20 cm;

- if the slope of the roof slope exceeds 30 degrees, the overlap can be reduced to 10-15 cm;

- if the slope is less than 12 degrees, both vertical and horizontal roof laps should be sealed with silicone sealant.

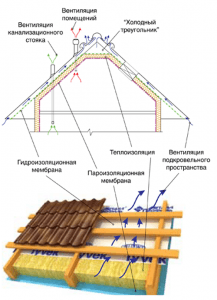

The installation of a roof from a metal profile begins with the installation of a waterproofing layer that prevents the penetration of moisture into the insulation, onto the rafters and the crate.

The hydro-barrier film is laid horizontally on do-it-yourself roof raftersstarting from the roof overhang. Such a gasket is fastened with small brackets between the rafters with an overlap of 15 cm, while not overtightening (the sag of the gasket should be approximately 2 cm).

It is also required to provide a gap of 2-3 cm between the insulation material and the hydrobarrier. In order to fix the film, a counter rail 2.5-5 cm wide is nailed.

Thermal insulation sheets are mounted under the waterproofing from the inside, and then the vapor barrier. Ventilation slats are fixed on top of the waterproofing layer, which will prevent moisture stagnation and, accordingly, rotting roof frame.

The roofing metal profile is installed on the crate, designed to provide the necessary strength, prevent deflections and fractures of the roof under the weight of snow and under the influence of wind.

When using roofing profiled sheets of a trapezoidal profile, a beam of 30 * 70, 30 * 100 or 50 * 50 mm is selected for the lathing with a rafter pitch of 900-1200 mm.

The manufacturer's instructions for roofing materials may contain more accurate parameters for the thickness of the lathing.

On the crate, at the height of the roofing profile, an upper end board is installed, to which end strips are attached. Under the groove plank, a dense flooring of boards is provided at the level of the crate, spaced 60 cm apart on both sides of the groove.

Installation of a groove made of galvanized steel is carried out with an overlap of 20 cm or more. Do not forget that when sheltering sloping roofs, additionally at the joints of the groove, the use of sealing mastic is provided.

The bottom plank of the groove is first fixed along the edges with the help of several self-tapping screws, while the final fixation is performed simultaneously with the fixing of the flooring. roofs.

So, the general arrangement of a roof from a metal profile layer by layer from bottom to top looks like this:

- internal lining of the attic space (drywall, lining);

- ceiling rails;

- vapor barrier film;

- roof insulation;

- roof truss system;

- vapor permeable waterproofing film;

- ventilation layer;

- crate;

- roof profile.

The high-quality execution of this particular scheme of installation of the roofing system will allow you to get a high-quality roof that is not afraid of either the standard load, or the appearance of condensate, or violations of ventilation, or heat loss.

Instructions for installing profiled roofing sheets

Now let's dwell in more detail on the technology of installation of roofing metal profile sheets:

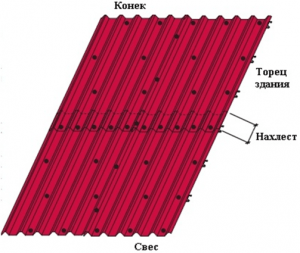

- Installation begins from the lower corner of the roof, while the profile sheets are overlapped and fastened to the wooden bars of the crate with self-tapping screws with rubber seals.

- If a gable roof is covered, then the installation of the profile usually starts from the right end, but if a hipped roof is covered, the profile is mounted on both sides, starting from the highest point of the slope.

- The installation begins with the installation of the cornice strip and its fastening with several self-tapping screws. A profile seal is inserted between the roofing sheet and the cornice strip. Provide for the removal of the cornice strip beyond the overhang by 3-4 cm.

- The profiled sheet for roofing is equipped with a gutter on one side, which is always left at the bottom during installation.

- With a slight slope of the roof slope, a sealant is provided in the longitudinal seam or the sheets are overlapped in two waves.

- When laying, the sheets are aligned along the overhang, and not along the joint.

In order to observe the correct order of installation of sheets, they are guided by the following rules:

- the mounted roof sheet is temporarily fixed at the ridge and the roof overhang with self-tapping screws, and the sheet is lowered beyond the roof overhang by 3.5-4 cm;

- then the next sheet is laid, while its edge is aligned with the previous sheet at the overhang and fastened in the same way;

- then one profiled roofing sheet is connected to the previous one on the crest of the wave by means of self-tapping screws in the direction from the roof overhang to the ridge in increments of 50 cm.

- Having mounted 3-4 sheets in this way, they are aligned along the line at the roof overhang and finally fixed.

- Fastening to the crate is carried out at the bottom of the wave, while passing every second wave.

- Further laying of the profile with a similar overlap (20 cm) and fasteners to the crate.

- Reliable fastening of the profile to the wooden crate is provided by means of special roofing self-tapping screws 4.8 * 35 mm.

It should be noted that when mounting a metal roofing profile, one should move exclusively along already fixed sheets, while placing one's feet in the grooves of the material located on the beams of the crate.

Advice! To avoid scratching the profile coating, the installer must wear shoes with soft non-slip soles.

When sheathing the facades of buildings, as well as their internal surfaces, a wall profile is used. Profile sheets of this type do not have a capillary groove, which ensures complete interchangeability of different parts of the profile and, accordingly, even easier installation compared to roofing sheets.

In conclusion, I would like to draw attention to the fact that moderate prices and technical characteristics of such material as a profiled roofing sheet make it very widely in demand.

Did the article help you?