The technology by which do-it-yourself rafters are erected for the roof is relatively simple. Of course, to build a large roof of a complex configuration, you'd better enlist the support of dexterous assistants, but if we are talking about a roof for a country house or a bathhouse, then you can do it yourself.

The technology by which do-it-yourself rafters are erected for the roof is relatively simple. Of course, to build a large roof of a complex configuration, you'd better enlist the support of dexterous assistants, but if we are talking about a roof for a country house or a bathhouse, then you can do it yourself.

And yet, "with a swoop" such a responsible task as the construction of a roof is not worth solving. Even the simplest cover of modest size, such as gable standard roof, requires appropriate theoretical training, the choice of suitable materials and scrupulous calculation.

You will also need to decide whether it will be necessary to produce waterproofing, insulation, and select roofing material.

Naturally, during the creation of the truss system, one should not forget about such an important aspect as safety precautions: after all, the work is carried out at a height, which means that the safety requirements for the performers are very strict.

Moreover, most of the work will be carried out on an inclined plane, so the issue of insurance is one of the paramount.

Also, a trussed roof implies very precise adherence to technology: any deviations from it may not appear immediately, but after several years of operation.

And having saved or “cheated” in the process of work, you risk getting a bunch of problems, of which the roof leak will be the least painful.

Forms and types of roofing

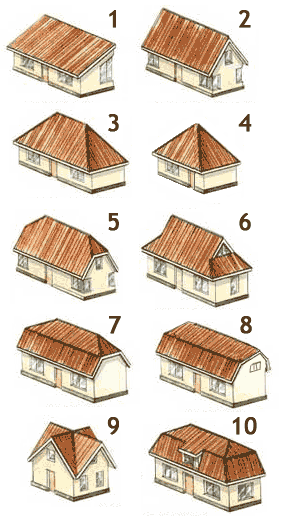

Before you make rafters for the roof, you need to decide on the shape of the roof. Depending on what kind of roof structure is planned, the rafters will have a different configuration - so you definitely cannot do without a design.

The project is best done using modern computer programs, since today there are a great many of them.

Modern architecture includes a variety of types and forms of roofing - and, of course, each type is characterized by a specific arrangement of roof rafters.

For simple buildings, such as a barn or a bathhouse, single-pitched and double-pitched structures are still used, while for residential premises such simple forms are of little use.

Most often, a tent-type roof is erected here, broken or T-shaped.However, the choice of the type of roof depends almost entirely on your taste preferences, because in terms of functionality, different types are not much inferior to each other.

Also, designing hip roof truss system, you need to take into account the material that will be used for the roof.

First of all, you need to know the specific gravity of the roofing material - after all, for example, for a roof made of ondulin (flexible tiles), the power of the rafters can be significantly lower than for a roof made of ceramic tiles or slate.

Design of the truss system

As mentioned earlier, the truss system for each type of roof has its own unique design. So, for example, the rafter system of a sloping roof is not applicable for the construction of a gable type roof, and vice versa.

And yet, some of the patterns on which the installation of roof rafters is based are universal. It is they who will be presented in this material.

To begin with, let's figure out what initial data should be taken into account at the design stage, which, without exaggeration, determines the entire success of the event:

- Firstly, if it is planned to insulate the roof, then it is advisable to develop the truss system in such a way as to make all subsequent operations as easy as possible for yourself. Considering the fact that the vast majority of brands of roofing insulation are produced in cuts of 600 or 1200 mm, we set the pitch of the rafter legs in the project to be 1.2 m. This will allow us to significantly facilitate the work of fitting and trimming the insulation.

- Secondly, as we noted earlier, the power of the rafter legs can be different.The optimal power is calculated taking into account the cross section of the rafter beam.

Note! The strength of wood is quite strongly influenced by the season of harvesting (winter wood is much stronger than summer wood), storage conditions, drying, and also the descent of resin. It is preferable to choose resinous bars, since resin, being a natural antiseptic, significantly extends the life of wood.

- Thirdly, throughout the roof, such as a hip roof, rafters are also needed in different sections. So, the most durable rafters are installed on the edges of the roofs, under the valleys (junctions of planes), at the junctions of several rafter beams. Particular care should be taken when choosing a beam for valley rafters, since the junction of planes is always a problem area both in terms of strength and in terms of leakage. It is optimal if the valley and rib rafters are 30-40% thicker than all the others.

Rafter protection

Before installing the roof - rafters, insulation, waterproofing and the roof itself - it is necessary to take care of the bio- and fire protection of the rafters. Protection of the truss system from fire is a mandatory requirement of SNiP for roofs of any type.

Treatment of rafter beams with antipyretics (substances that reduce flammability) and antiseptics (substances that prevent wood decay) should be carried out before the rafter system is mounted - this way we get the opportunity to evenly process all areas, paying special attention to the intended joints.

To apply protective compositions, we use a flat, wide brush with a long pile.It is also mandatory to use safety goggles and (preferably) a respirator.

It is better if the composition is applied in two layers with pre-drying - so the wood is better saturated and the effect of protective compounds will last much longer.

You can work with rafters only after the antipyretics and antiseptics are completely dry.

After the project is approved, the material is selected and processed with protective compounds, you need to figure out how the roof truss system is built with your own hands.

Installation of rafters

The truss structures of the roof of the house are mounted according to the following scheme:

- To begin with, we lay the Mauerlat - a beam on which the entire rafter system will rely. Mauerlat is laid over the walls on a concrete belt, in which galvanized metal studs with a diameter of at least 10 mm are installed in increments of not more than 120 cm.

Note! To ensure waterproofing, a layer of roofing material or other material (of the TechnoNIKOL type) should be placed under the Mauerlat.

- We lay the timber near the studs, determine the places for drilling the holes, and after drilling, we put the Mauerlat on the studs so that the protrusion of the stud is 2-30 mm. We fix the Mauerlat with nuts with large diameter washers.

- After the Mauerlat is installed, we begin directly attaching the roof rafters to the support beam. We set the rafter leg with a notch to the required position and fix it to the Mauerlat with a bracket made of galvanized steel (using self-tapping screws) and a bracket. The bracket prevents transverse displacement of the rafter along the Mauerlat, and the bracket prevents longitudinal displacement.

- In the same way - with the help of a steel bracket - the rafters are connected to the ridge beam.You can additionally strengthen the ridge mount with the help of an intermediate rail connecting the opposite rafters in the shape of the letter "A"

- To connect the rafters to each other, we use studs with a diameter of at least 8 mm (for a roof made of metal or ondulin) or 10-12 mm (for a roof made of cement-sand or ceramic tiles).

Note! To prevent the rafters from moving relative to the axis of the stud, two studs are used at once for one node. The studs are inserted into pre-drilled holes and fixed with nuts through a reinforced washer.

In some cases, it may be necessary to lengthen the rafter beam. If such a need arises, it should be borne in mind that the overlap of the beams during splicing should be at least 1 m. The beams are interconnected by studs, the diameter of which must be at least 10 mm.

When installing rafters with a length exceeding 6 m (for example, when a large t-shaped roof truss system is being erected), it is necessary to exclude their sagging along the length - both under their own weight and the weight of the roof, and under the weight of snow in winter.

This can be done in two ways: either by installing a middle run - a thick load-bearing beam across the rafters, or - by installing transverse beams or struts.

The latter method is preferable in the case when it is planned to equip the attic - it will be possible to fix the ceiling of the attic floor on the spacers. That is why transverse reinforcing beams are most often used.

After the installation of the building rafter system is completed, we cut the rafters at the level of the eaves.After that, you can fill the battens of the batten on the rafters - or proceed with waterproofing work and laying insulation.

According to this algorithm, the rafter part of the roof is equipped. And when the rafters are ready, and they are made with high quality - you can safely proceed to the roofing work itself!

Did the article help you?