The construction of the rafter system is one of the most important stages in the construction of the roof, and the fastening of the elements plays a very important role here. This article will talk about how various options for attaching rafters are performed, in particular sliding rafters, and what functions they perform.

The construction of the rafter system is one of the most important stages in the construction of the roof, and the fastening of the elements plays a very important role here. This article will talk about how various options for attaching rafters are performed, in particular sliding rafters, and what functions they perform.

Building a rafter system is not an easy task, which must be treated with all responsibility.

Any oversight or defect can lead to damage or destruction of the roof, so elements such as sliding rafter support must be made with the highest quality. Let us consider in more detail the main stages of the construction of the truss system.

First you need to prepare its individual elements:

- The topmost element of the roof structure is called the ridge.For its correct manufacture, after mounting the first element, make a template according to it, according to which the subsequent elements of the ridge will be made;

- In the case of building a large house, lengthening of the boards is required. To do this, holes for bolts are made in the docking board. To avoid damage to the wood, holes are drilled with a drill.

Important: when doing this, make sure that the distance between the end of the docking board and the nearest hole is at least 10 cm. In addition, drilling holes too often can cause cracking of the board, so holes should be drilled randomly, keeping a distance of about 10 centimeters between them.

When calculating the rafter system, it is also necessary to take into account future roof loads, which include the weight of the roof covering, as well as snow and wind loads.

In addition, it is important to take into account the shrinkage of wood. For example, if the log section is 195x195 mm, the total shrinkage along the gables or cornices will be about 6%.

After completing the required calculations and preparing the elements, you can proceed directly to the installation of the rafter system.

It consists of the following elements:

- Roof ridge;

- Supports of rafter legs on intermediate beams;

- Supports the legs of the rafters on the overhang of the eaves.

Consider the fastening of these elements in more detail.

For fastening roof ridge special docking plates are used, the use of which does not give rise to any additional performance issues.

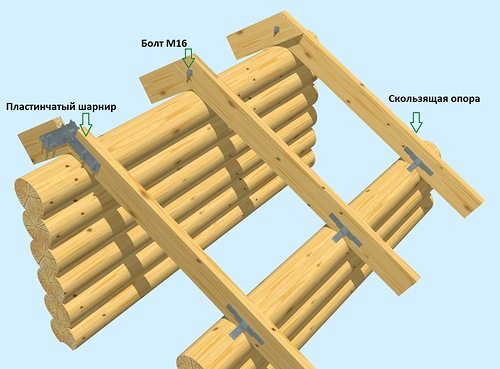

To support the rafters to the intermediate beams, special sliding elements are used, also called "rafter slides".

The sliding rafter support is always mounted perpendicular to the rafter itself. To do this, over the main part of the "slider" an accurate gash is made in the bars, which should ensure the correct installation of the element at an angle of 90 degrees to the rafters.

The sliding rafter system provides for the installation of the slider in the most extreme position, which provides maximum rafter travel during the shrinkage of the house.

In this case, the shrinkage of the wood will not affect the rafter system in any way, and after the stabilization of the process, it will be possible to start laying a permanent roof covering, which will then last for many years.

Using sliding rafters

Sliding rafters are used in the construction of houses from timber or logs, in which noticeable shrinkage is observed in the first years of operation. A very important role in this is played by the technology for fastening the rafter legs to the log house, which is especially important for a log pediment.

Shrinkage of such houses occurs unevenly and directly affects the dimensions of the entire structure. Thus, the total shrinkage of the building height can be up to 10%.

The technology of using sliding rafters involves the installation of wood rafters on a ridge log. At the same time, the rafters are connected either with an overlap or in a joint using nails or bolts and steel plates.

Important: self-tapping screws do not cope with heavy loads quite well, so it is not recommended to use fasteners for rafters with their help.

The cross section of the rafters is determined primarily by the weight of the roof under construction. The most commonly used edged board, the width of which does not exceed 200 mm, and the thickness is 50 mm.

It is not recommended to rigidly fasten the rafter legs to the Mauerlat, which can cause the roof to sag or the walls of the log house to burst.

Sliding fastening of the rafter legs to the frame is carried out using special brackets made of 2 mm steel and equipped with a corner that ensures the sliding of the support.

They are sold in hardware stores and are quite cheap. . An important point in the application of this technology is that the guide ruler must be attached strictly parallel to the rafters, and the corner on the log must also be perpendicular.

This prevents the rafters from skewing during the shrinkage of the house. The fastening of the corner is carried out at the level of the ruler, which allows the rafters to slide further along its entire length during the shrinkage of the building.

Rafter fastening

In the event that the rafter is simply rested against the beam and a force is applied to it, its end will simply begin to slide along it, which will result in the rafter slipping and the destruction of the roof.

In order to prevent such slipping and secure the rafters securely, special connections are used:

- Tooth with emphasis;

- Tooth with spike and stop;

- Emphasis at the end of the beam.

The connection is made with one or two teeth, depending on the angle of inclination of the rafters. Such fastening of the rafters to the beams allows you to transfer pressure from one element of the rafter system to another.

The connection of rafters and beams with a single tooth is used in the case of a sufficiently large angle of inclination of the roof, i.e. with an angle between the beam and the rafters exceeding 35 degrees:

- A tooth with a spike is made in the heel of the rafter's leg;

- An emphasis is cut out in the beam, in which there is a socket for a spike, the depth of which should be 1/4 - 1/3 of the thickness of the beam. The great depth of the nest can cause it to weaken;

- The cut is made at a distance of 25-40 cm from the edge of the hanging beam, preventing a possible chipping of its end under the load created by the rafters.

Single teeth are usually made in combination with spikes to prevent lateral movement of the leg of the rafter. This method of connection is called a tooth with a spike and an emphasis.

In the case of a flatter roof, the angle of inclination of which is less than 35 degrees, the installation of rafters is carried out with the expectation of increasing the friction area against the floor beam. Simply put, they increase the area of \u200b\u200bsupport of the rafter leg on the beam.

For this, a cut is made with two teeth, which can be performed in several versions:

- Two stops (with a spike and without a spike);

- Two stops with spikes;

- Lock with two spikes, etc.

The first option is done as follows:

- In the beam, a spike with an emphasis is cut out for one tooth;

- An emphasis is cut out for the second tooth;

- In the rafter, an eye with an emphasis is cut out for the first tooth;

- For the second - cut out the emphasis.

The teeth are cut to the same depth. In the case of different cutting depths, the first tooth with a spike is cut into 1/3 of the beam thickness, and the second - by 1/2.

A less common way to attach rafters to a beam is to end-to-end:

- An abutment tooth is cut out in the rafter leg;

- One plane of the tooth is placed on the very edge of the plane of the beam;

- The second plane of the tooth rests against a cut made in the beam, the depth of which is 1/3 of the thickness of the beam.

Important: the stop tooth should be cut at the maximum possible distance from the edge.

The reliability of fastening is increased by additionally connecting the rafters and beams with clamps or bolts, after which the entire corner is attached to the wall of the house with wire loops or iron strips.

Rafter fastening is made to an anchor bolt or a crutch embedded in the wall.

When making connections to the rafter system, the following fasteners are used:

- Wooden roof elements - plates, dowels, bars, overhead or insert triangular scarves;

- Metal elements - screws, nails, bolts with washers and nuts, clamps, hinges, linings, various steel corners, etc.

The reliability of the truss system largely depends on the quality of fastening of its various elements to each other.

In the case of wooden houses, sliding rafter systems make it possible to ensure the safety of the roof during the shrinkage of wood in the first years of operation, therefore, installation of both the rafter system itself and its individual elements and fasteners should be carefully and responsibly.

Did the article help you?