During the construction of cottages and country houses, rafter systems used in residential buildings are used. This article will talk about how a rafter system is designed, what a rafter plan is and how it is drawn up to facilitate the calculation of the system.

During the construction of cottages and country houses, rafter systems used in residential buildings are used. This article will talk about how a rafter system is designed, what a rafter plan is and how it is drawn up to facilitate the calculation of the system.

Rafters for residential buildings are most often made of wood. Such truss systems are usually made in the form of a triangle, although other designs are sometimes used.

If it is necessary to save living space, attic truss systems are used, which make it possible to equip another living room in the attic.

Design of roof systems and rafters

Designing a rafter system is a rather complex task that requires special skills and knowledge.To do this, it is necessary to correctly calculate the snow and wind, the optimal weight of the system.

Therefore, the greatest efficiency and durability of the built house can be achieved if the calculation and drawing of the truss system is performed by a competent, qualified specialist with experience in performing such work.

The most important points to consider when designing a roof are:

- Type of roof being built;

- slope angles;

- The material used to cover the roof;

- choice of section of rafters;

- Calculation of the structures of the rafter system.

At the same time, the slope of the slopes also affects the calculation of the strength of the supporting structure and the choice of material that will cover the roof.

Most of these materials directly affect the design of the truss system, therefore, the coating material must be selected at the design stage.

The truss structure should be carefully calculated when designing the roof, since the shortcomings made in the assessment of loads can cause both deformation of the rafter structure and violation of the roof covering during operation, and collapse of the entire roof.

The load-bearing structures of the roof, consisting in the case of a pitched roof of battens and rafters, ensure its stability and strength.

The structural layout of the rafters depends on the following parameters:

- roof shape;

- The presence of internal supports and their location;

- The length of the overlapped space.

When drawing rafters, it should be borne in mind that rafters or trusses of rafters are hanging and layered (the most common type).

Most often, the design of the rafters is made in the form of a triangle, providing maximum rigidity and efficiency.

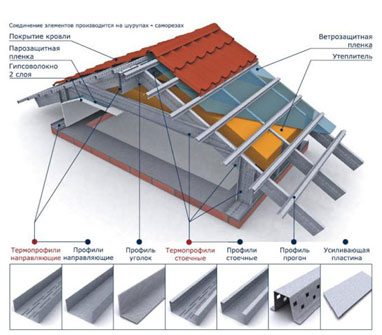

Complex rafter trusses include a number of different additional elements, such as:

- Rafter beams, also called rafter legs;

- puffs;

- Crossbars;

- Racks;

- Struts, etc.

Let's take a closer look at the two main types of rafters:

- Laminated rafters are installed in houses where the middle wall is the load-bearing wall. They include two rafter legs, the lower ends of which rest on the Mauerlats - the bearing bars, and the upper ones - on the ridge run, which is supported by racks. Racks are installed on a bed, located on a bearing internal wall. Mauerlat and lying serve to distribute the load on the walls. In the absence of longitudinal internal walls, the rafters should be supported on transverse internal walls or on pillars, the distance between which does not exceed 6.5 meters. With one additional support, the width of the overlapped room can be increased up to 12 meters, and with two supports - up to 15 or 16 meters. The increase in span complicates the design, since it becomes necessary to introduce additional roof elements, such as struts and struts, to increase the stability and lateral rigidity of the rafter system, turning the rafter structure into a truss.

- hanging rafters are used in the absence of internal supports and rely only on external walls. The composition of the hanging rafters includes inclined rafter legs and an extension, which is a horizontal bar that receives the thrust from the legs of the rafters. With the lower ends of the rafter legs, with the help of a puff, they rest on the Mauerlats, and for the upper ends, the rafters are fastened in the ridge.The simplest version of the hanging rafters is a triangular symmetrical truss, and the volume of the overlapped space can be from 7 to 12 meters. You can strengthen the structure with a special screed - crossbar.

Important: it should be noted that the manufacture of hanging rafters is a rather laborious process, and their cost significantly exceeds the cost of layered ones. Therefore, quite often, in order to reduce the cost of construction, combined systems of rafters are equipped, which include both hanging and inclined rafters.

Development of a rafter plan

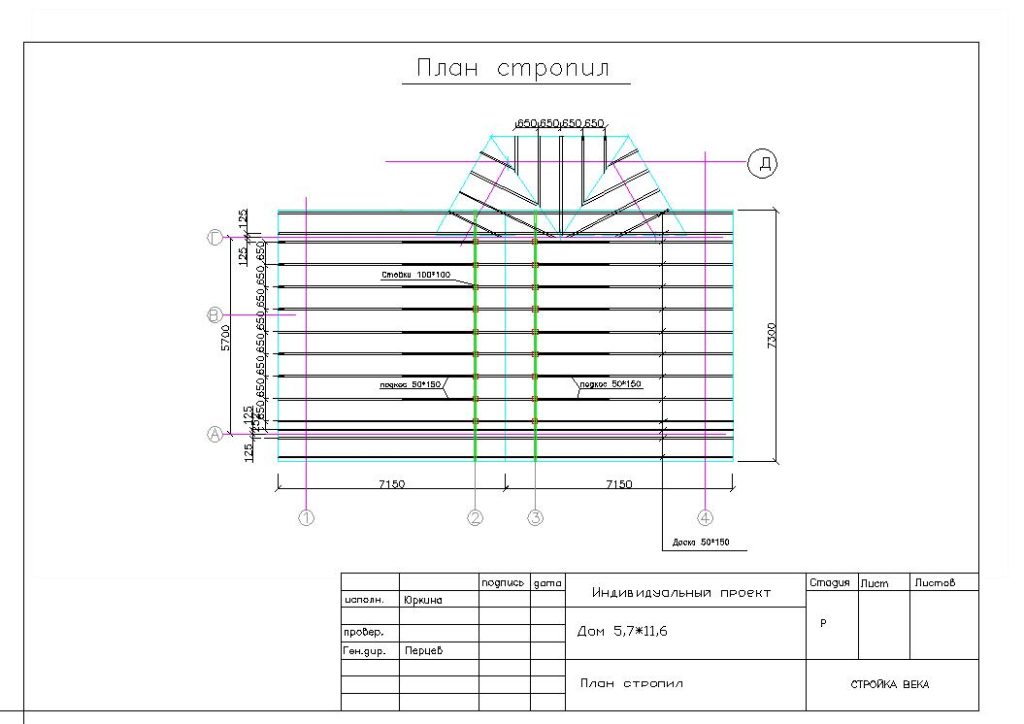

When developing a rafter plan, the following procedures are performed:

- Application of modular coordination axes, to which the values of the thickness of the main walls of the building are attached. In this case, the extension of the crowning cornice of the structure used is displayed on the plan of the outer walls in the form of a contour line;

- On the plan, smoke and ventilation ducts and pipelines are drawn, the location of which is necessarily taken into account in the process of placing the elements of the designed rafter system;

- They develop a plan for the selected roof shape in the form of a sketch, which should also take into account the location of the walls. A ridge, valleys, ribs, as well as the following elements are applied to the plan in the form of lines:

- The shape of the roof slopes;

- The direction of the slope of the slopes;

- The location of the dormer windows;

- Location of gables, etc.

- Using the roof plan, a rafter system plan is drawn, on which the placement of the following elements should be indicated:

- Rafter beam;

- Mauerlats;

- Rafter legs with fillies and puffs, based on Mauerlats;

- Racks, as well as longitudinal struts, providing the necessary spatial rigidity of the truss system (displayed as a dashed line);

The cross-sections of various elements take indicative values depending on what type of wood will be used in construction (boards, beams or logs). The step of the rafters, that is, the distance between them, is selected depending on what kind of scaffolding is used in the construction of the roof, as well as on the weight of the material used to cover:

- Step wooden rafters is 100-120 cm;

- The pitch of the rafters made of beams is from 150 to 180 cm.

In addition, the distance between the rafters can change when passing chimney or ventilation pipes between them.

In addition, these pipes can be skipped by interrupting the rafter legs; for this, their free ends rest on lintels made of wood located between adjacent rafters, for the fastening of which a special rafter is washed down.

In the case of gable or gable roofs, dormer windows are placed in gables located at the ends. This increases the efficiency of attic ventilation in the warm season.

When developing a four-pitched roof project, elements such as oblique diagonal legs of rafters, sprigs resting on them, as well as dormer windows located on the hips, should be displayed on the plan.

In the event that an attic floor is equipped in the under-roof space, the plan should also display the upper beams of the framing of the frame walls, on which the rafters will rest.

It should also be taken into account that the development of a plan for the rafter system should be carried out in parallel with the development of a plan for various structural sections of the designed building, which should be interconnected.

- On the drawing of the truss plan, the values of the distances between the modular axes of the designed building are put down, to which the values \u200b\u200bof the thickness of the walls are attached. Dimension lines, on which a chain of steps between the rafter axes is marked, are drawn on the plan closer to its contour. Inside the plan, the distances between the racks, ventilation and chimney pipes, as well as between various structural elements of the truss system are indicated. In addition, callouts must be displayed on the plan, on which the values of the lengths and cross sections of the listed elements will be indicated.

The truss system is the most important element of the construction of the roof being erected, on the correct design of which such indicators as the reliability of the roof, its safety and the duration of the service life depend.

Therefore, without having the required skills and abilities, it is better not to take on the preparation of a rafter plan, but to entrust this work to a qualified specialist with the necessary experience.

Did the article help you?