Any construction ends with the arrangement of the roof. The main load-bearing element of the roof is the rafters, including inclined legs, vertical posts and struts. The installation process of rafters does not tolerate negligence and haste, it is responsible and quite laborious. The reliability and strength of the roof depends on how correctly the scheme of the truss system is chosen and how it is installed. This will be discussed in the material of the article.

Any construction ends with the arrangement of the roof. The main load-bearing element of the roof is the rafters, including inclined legs, vertical posts and struts. The installation process of rafters does not tolerate negligence and haste, it is responsible and quite laborious. The reliability and strength of the roof depends on how correctly the scheme of the truss system is chosen and how it is installed. This will be discussed in the material of the article.

Rafter manufacturing

The truss system can be made of wood or metal, or combine two materials.

Let's start with how to assemble a truss system from wood. There are two options for obtaining a truss system:

- order the manufacture of roof trusses in the factory;

- make it yourself at the construction site.

Prefabricated truss elements are produced on special equipment using metal plates that are placed at the joints.

Such a scheme of rafters allows you to make truss structures of any complexity. The factory can produce fully finished truss trusses or their elements with the possibility of collection.

Self-manufacturing involves the connection of rafter elements by various methods:

- groove-thorn;

- using clamps;

- using bolts, staples and nails.

The most common connection is fastening with staples or nails. But it is worth paying attention that when using not dried material, the connection loses its strength as it shrinks.

Bolted connection avoids this. However, holes drilled under it weaken the log, board or rafter. You can also fix the elements of the rafters with the help of steel fittings.

On the question of how to properly make a metal truss system, there are also two solutions. As in the case of a wooden structure, the first way is prefabrication.

Currently, elements of rafters are made of galvanized rolled products. The weight of such elements, in comparison with black rolled products, is much less, which facilitates the process of their installation.

Self-manufacturing of a metal truss structure involves the purchase of corners and channels of the required section and welding.

Advice. The manufacture of metal rafters is a rather laborious production. In addition, there are difficulties with fitting this material on the roof. Therefore, in most cases, and especially when the manufacture of rafters is done independently, schemes of truss systems made of wood are used.

Connection of rafter elements

If you chose coniferous wood for arranging rafters, then you should know how to connect wooden structural elements:

- single or double tooth;

- connecting rafter legs to the ends of the puff;

- bolted connection or with clamps;

- connection of puffs and struts with brackets;

- fastening the rafter elements to the Mauerlat, with the ends of the rafter legs adjoining it;

- alignment of rafters with a filly.

Attention. To avoid slipping of the rafter legs along the tightening, it is necessary to connect these elements with a spike or tooth.

Installation Features

The installation of the rafter system is carried out with the release of the rafter legs beyond the lines of the walls of the building structure. For wooden buildings, the size of the overhang is more than 55 cm.

To prevent damage to the truss structure by wind loads, truss trusses must be fastened to the walls.

If the frame is wooden, then the base of the truss is fixed to the crown of the frame. In the case of fixing the structure to brick walls, a clamp is put on the rafters, which is attached to a pin driven into the wall. To give the structure additional rigidity, the rafter beams are connected by jumpers.

During installation work on bulky roofs, the rafter system requires the installation of additional supports that protect the rafter legs from deflection. For the installation of roofing, a crate is arranged perpendicular to the rafter legs.

Installation of the truss system

In the question of how to install a truss system, the type of roof plays an important role. Let's consider two options:

- With a shed roof, the installation scheme is quite simple. The beams of the structure rest against the opposite wall. The angle of inclination of the roof is provided by different heights of the supports (the acceptable slope option is 45-60 degrees);

- For a gable roof, a more complex truss structure is required. Usually it is represented by a triangle, in which at the top the beams are connected on the ridge, and the lower base is attached to the supporting pillars or Mauerlat.

In two versions, both on a single-pitched roof and on a two-pitched roof, the beams of the truss trusses are installed parallel to each other.

Estimated value of rafters

Depending on the roofing, the massiveness of the roof structure, the climatic zone where the construction site is located, a rafter system calculator is developed, that is, the linear dimensions of the rafter legs and the step of their placement in the system.

It is important in the calculations to choose not only the length of the beams, but also the cross section of the beam for them.

It, in turn, depends on:

- from the size of the length of the rafters;

- step of their installation;

- calculated value of loads.

Recommended sections for elements of the truss system:

- for rafter legs - timber 50x150, 75x125, 100-150 mm;

- for Mauerlat - timber 100x100, 150x150 mm;

- for runs - timber 100x100, 100x200 mm;

- for puffs - timber 50x150 mm;

- for crossbars - timber 100x150 mm;

- for racks - timber 100x100 mm;

- for the filly - timber 50x150 mm.

Advice. All design values are best determined at the design stage. This will further lead to easier work and the acquisition of strength properties by the truss structure.

Type of truss systems

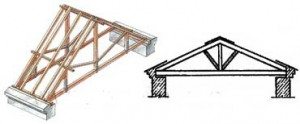

The most common version of the truss system is a layered truss truss, which is installed on objects that have an average load-bearing wall.

It includes:

- two rafter legs resting on a ridge run and a Mauerlat;

- racks resting on a bed.

More complex trusses include hanging truss systems resting on external walls.

This design includes:

- inclined rafter legs;

- puffs;

- Mauerlat;

- bolt.

Such a system is more laborious to install and more expensive than lightweight structures, so many builders on complex roofs install combined truss structures, consisting of layered and hanging trusses.

Installation instructions

On whatever roof structure you carry out work on the installation of the truss system, there is a general instruction for its installation.

It contains the following rules:

- It is very difficult for one person to install roof truss elements on the roof. Assistance is required to lift the elements to the roof, as well as during installation work on the installation of roof trusses.

- Create a mauerlat (a bar with a square section). The timber is laid along the edge of the wall from the inside, and fastened with metal anchors.Temporary supports are being arranged to establish a ridge beam, which is located parallel to the wall, in strict horizontality.

- Rafter elements are prepared, adjusted to the required size. The upper and lower parts of the rafters are tightly aligned with the plane of the ridge and Mauerlat, respectively.

- Extreme truss trusses are installed, serving as a guide for the rest of the rafter legs. When installing and fixing the rafters, a strict distance between them (step) is observed.

- In the event that the length of the rafters is less than required, it is lengthened. To do this, the ends of the beams are cut at an angle of 90 degrees, which ensures a snug fit of the elements. Overlays 70 cm long are nailed at the joints. This reduces the possibility of deflection that occurs under the influence of the total load.

Advice. The extension must be constructed so that there is an alternation of joints in the lower and upper parts. This will provide the roof strength and evenness.

One way or another, the installation of rafters must be carried out with extreme precision. When using quality materials for the rafters and properly installing them, the roof structure will be reliable.

This will continue to protect the house from precipitation and other negative environmental influences.

Did the article help you?