The roof not only protects the house from bad weather, but also is the logical conclusion of its architectural image. How competently calculated and correctly installed the supporting structure of the roof depends not only on the appearance of the roof, but also on its functionality during operation. In our article, we will consider the device of rafters, their types and types, as well as methods of fastening and installation.

The roof not only protects the house from bad weather, but also is the logical conclusion of its architectural image. How competently calculated and correctly installed the supporting structure of the roof depends not only on the appearance of the roof, but also on its functionality during operation. In our article, we will consider the device of rafters, their types and types, as well as methods of fastening and installation.

Recall that the roofs are pitched and flat. In individual suburban construction, gable roofs are most often used.

Their design feature: two planes located on the same level, which, with their bearing part, rest on the walls of the house themselves. An attic is formed under the slopes of roofs of this type, it can be cold and warm (mansard).

Depending on what material the roof will be covered with (taking into account its architecture), the slope of the roof depends. It is measured in degrees.

How to determine the reliability of the truss system?

The reliability of the system depends on many factors, namely:

- From how correctly the type of truss system is chosen.

- From how firmly the nodes in the truss system are connected.

- From how accurately engineering calculations are made for the designed loads on the roof.

- From the practical skills and professionalism of carpenters and roof installers.

From this follows the conclusion: the installation of the truss system is a responsible event, which must be started after the calculations have been made, the drafting and plan of the truss system.

Yes, and it is best to entrust such a responsible matter to specialists. In a handicraft way, you can also build a reliable roof, but from high-quality material and subject to all norms and rules.

Rafter system: structural units

The truss system is the basis of the supporting structure of the roof. It transfers the load to the internal supports from the weight of the roof itself and the snow cap.

It is quite clear that with an incorrect calculation, the truss system simply cannot withstand the load, which is fraught with scary even to imagine ...

The design of the truss system depends on:

- from the shape of the roof;

- from where the internal supports are located (if any);

- on the size of the spans of the floors;

- from expected operating loads.

The triangle is the main figure in the design of the truss system. No less important and another element is the rafter legs. They support the crate, and lay them along the roof slope.

Rafter legs are abbreviated as one word "rafters".

The main types of rafters

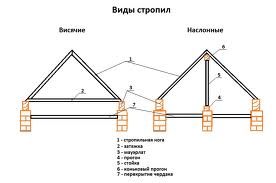

In modern construction, there are two types of rafters:

- Hanging.

- Layered.

Consider their device.

Hanging rafters rest on the extreme two supports. Often, the walls of the building act as supports. There are no intermediate supports here.

Therefore, such a design not only works on bending and compression, but also produces a bursting horizontal force, subsequently such a load is transferred to the walls.

This effort helps to significantly reduce the tightening - it connects the rafter legs. Usually the puff is located at the base of the rafters and, as a rule, performs the function of a floor beam.

When building a mansard-type roof, this option is most often used.

Layered rafters are installed in those buildings where there are intermediate columnar supports or an additional middle wall. The ends of the layered rafters rest on the outer walls of the house, and their middle part rests on the support or inner wall.

As a result: all elements of the layered rafters work as beams only for bending. Having the same width of the roof of the house, the layered structure is much lighter than other structures. Thus, the load on the building is reduced significantly.

A little advice: in the case when you install a single roof structure over several spans, alternate between layered and hanging trusses.In those places where there are intermediate supports, use layered rafters, where there are no such supports - hanging.

Most often, the rafters rest on a rafter beam - it is also called a support beam or Mauerlat. If the house is wooden, then the Mauerlat is the upper beam or log (the crown of the log house).

In houses built of blocks or bricks, the Mauerlat is specially installed. It can be a wooden beam, which is installed at the level of the inner surface of the wall (flush). From the outside, the Mauerlat is fenced with a ledge of blocks or bricks.

It is important to know: between the Mauerlat and the brickwork, it is imperative to lay a waterproofing layer. If this advice is neglected, then subsequently the wooden beam will be exposed to moisture, which will adversely affect its properties and lead to a decrease in the service life.

What material is used for the construction of roof structures?

For the construction of truss and other wooden roof structures, wood of different varieties of coniferous trees is used. Regardless of the type of wood and its moisture content, it must comply with the requirements of GOST 24454-80 and GOST 8486-88.

Only then wooden structures will be of high quality and will be able to perform their functionality at 100%, and will also serve the maximum period.

The structures of the truss system must belong to the first and second groups of limit states. And this means that such structures will be able to satisfy the bearing capacity of the design requirements.

They will also be able to ensure normal operation and, regardless of the duration and nature of the loads, will not be deformed.

If, in relation to such structures, constructive measures are provided, which are indicated in the chapter "Wooden structures" SNiP 11-25-80, and moreover, protection is additionally made by various means against fire, moisture and biodamage, then your roof truss system will serve faithfully for hundreds of years.

Basic rafter work

Depending on the size of the span, the weight and type of roof, the load of the snow cap, the distance between the rafter legs, as well as their cross section, is determined.

Raftering is a rather complicated process. How well you perform it correctly depends on the longevity of not only the roof, but the entire building.

The main error in roof rafters: incorrect calculation of the section of the rafters. What is the risk? After a while, the rafters will begin to sag, respectively, this will affect the quality of the entire roof structure.

A little advice: to avoid such unpleasant moments, special gratings and additional fasteners for rafter legs - crossbars allow.

It is important to know: rafter legs with a crossbar must be connected to the floor of a tree, and in addition they must be attached with bolts, wooden nails, staples.

The most commonly used sections are:

- for bars - 16-18x12-14 cm;

- for boards - 16-18x4-5 cm;

- roundwood forests - 12-16 cm.

In the axes between the rafters from the beams and logs, distances of 150-200 cm are accepted, between the rafters from the boards - 100-150 cm.

Tip: Pay special attention to cutting the rafter legs into the Mauerlat. We recommend attaching them additionally with brackets or wire twists. This contributes to a more reliable fastening of the roof, since the twisting covers the Mauerlat with one end, and with the other it needs to be fixed to a crutch (it is hammered lower into the wall).

Filly should be nailed at the end of each rafter leg. They can be done from the board. Formwork is nailed to the filly along the entire eaves along the slope. It is the basis for the boardwalk, on which the roofing material will be attached.

A special nuisance of the truss system is its expansion. To prevent this from happening, it is necessary to ensure that the rafters are securely fixed in the ridge.

So that no displacement along the slope occurs. Such joint strength can be achieved by cutting the rafter legs into the floor, as well as by an overlay and an additional fastening rafters to beams bolts and dowels.

The upper ends of the rafter legs exert pressure through the girders, racks and struts on all of the internal roof supports.

Ridge runs are best made from beams with a section of 12x18 cm or from logs with a diameter of 18 to 22 cm.

Important: all interface elements in the rafter system must be reinforced with metal fasteners - bolts, nails or staples.

Design features of complicated rafters

Some roof types have additional requirements or design restrictions. This primarily applies to those roofs on which heavy roofing material will be laid.

So, for example, one square meter of ceramic tiles weighs almost 50 kilograms.

Accordingly, it is necessary to calculate the truss system in such a way that it can withstand the maximum load. It is quite clear that the cost of the roof will increase by 15-20%, since more lumber will be needed.

Despite the fact that a soft roof is almost five times lighter than a ceramic one, it must be laid on a crate made of solid plywood or boards. You also need to consider that you will have to use lining carpets. Therefore, it is also not necessary to count on saving building materials.

Did the article help you?