Special requirements are imposed on the strength of roof support systems. The characteristics of the truss system are significantly influenced by the way in which the rafters were fastened to the beams.

Special requirements are imposed on the strength of roof support systems. The characteristics of the truss system are significantly influenced by the way in which the rafters were fastened to the beams.

When designing and building a roof, you need to take into account many points that can create loads on load-bearing systems.

Among them:

- The thickness of the snow cover;

- The strength of the wind;

- The weight of the roofing material and other components of the roofing "pie";

- The presence of some equipment on the roof and other loads.

The main structural elements that take on most of the load are:

- Rafters or roof trusses;

- Composite beams.

Therefore, during the construction of the roof, the quality of the material used for the manufacture of these elements is given increased attention.But, just as seriously, you need to take how the main elements of the roof will be fastened together.

Today it is customary to mount the rafters to the walls of the building as follows:

- Using Mauerlat;

- With the help of rafter bars and puffs;

- With fastening through the beams used as a ceiling;

- With fastening to the upper crown of the walls during the construction of log cabins;

- With fastening to the elements of the upper strapping during construction using frame technology.

Fasteners for rafters

When assembling the truss system, both wooden and metal products are used.

Wooden fasteners:

- Bars;

- triangles;

- Overlays for forming a spike;

- Nagels;

- Plates.

Metal fasteners:

- Nails, bolts, screws, studs;

- Staples, clamps, taverns;

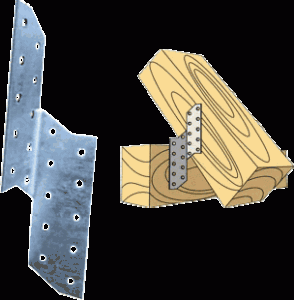

- Steel corners;

- Special devices for attaching rafters - sleds or sliders;

- Perforated plates;

- Toothed or nail plates;

- Various embedded details.

Methods for attaching rafters to Mauerlat

This is one of the most common methods of attaching rafters to their underside. It must be said that not all masters are able to perform this work without errors, which, of course, affects the strength of the roof.

A cutout must be made at the bottom of the rafter leg (builders often call it a “notch”). As a result, the leg, as it were, is put on the Mauerlat beam.

It is impossible to install rafters without this cutout, since the flat edge of the beam will simply slide off the beam, it is only a matter of time.

Is it necessary to make a reciprocal notch in the Mauerlat? It all depends on what material the Mauerlat is made of.

If it is solid hardwood, then it is recommended to make a slot (not a recess!), Which, in combination with a specially made slot in the rafter leg, forms a persistent lock.

If the Mauerlat beam is made of coniferous wood, then such cuts should not be made, this will only weaken the structure.

To visually see how the loads act on the roof, you can conduct a simple experiment. You need to take a hardcover book and, opening it approximately in the middle, place it face up on a table or any other surface.

Now you need to lightly press on the spine of the book, simulating the pressure of snow, and just as slightly press on the side of the cover, creating a semblance of a wind load. What will we see? That the edges of the cover are trying to part down and to the sides.

So our roof, under the influence of a real load, will tend to “move out” to the sides and down, so it is necessary to use constructive solutions that will prevent such slipping.

One of these solutions is cutting notches in the rafter leg.

When connecting a beam to a rafter leg, the following connections are used:

- Tooth with emphasis;

- Tooth with spike and stop;

- Emphasis on the beam.

Cutting by single tooth method. This connection method is used in cases where the roof has a large angle of inclination. In this case, the angle between the rafter leg and the beam exceeds 35 degrees.

A tooth with a thorn is cut out in the rafter leg, and a socket is created in the beam for the thorn to enter.

Advice! The depth of the nest should not exceed 1/3-1/4 of the thickness of the beam itself, otherwise the beam may weaken.

Cutting is recommended to be carried out at a distance of 25-40 cm from the edge of the beam to avoid the risk of chipping. A single tooth is recommended to be created in combination with a tenon, this will avoid lateral movement of the connection.

Cutting by double tooth method. This method is used for more sloping roofs, when the angle between the parts to be joined is less than 35 degrees.

Cutting can be done in several combinations:

- Two spikes;

- Emphasis, supplemented with a thorn, and emphasis made without a thorn;

- Lock connection with two spikes and other options.

The insertion depth for both teeth is usually the same. But you can use a cut to a different depth. For example, the first tooth, supplemented with a spike, is cut into a third of the thickness of the beam, and the second - by ½.

There is another method roof rafters, namely, the connection of the rafter leg with the beam, although it is used quite rarely.

In the rafter leg, a stop tooth is made so that one of its planes simply lies on the plane of the edge of the beam, and the second plane rests on the washed down made with a depth of a third of the thickness of the beam.

To make the design more reliable, in addition to cutting, use connections with bolts, clamps, wire loops or strips of metal.

Methods for fastening rafters in the ridge part of the roof

In modern construction, three main methods are used to connect rafters on a roof ridge.

- Butt connection.In this case, the upper part of the rafter leg is cut at an angle equal to the angle of inclination of the roof and abuts it against the corresponding rafter leg, on which the trimming was carried out with the opposite slope. Such pruning can be done according to a pre-made template. Or, in order to create more tension at the stop, trimming is carried out on the spot, making a cut through both bars at once. After such a cut, both planes will be adjacent to each other. Then do-it-yourself roof rafters connected with long nails.

Advice! When using this method, you can further strengthen the connection by using a wood or metal pad, which is fixed at the junction with bolts or nails.

- Mounting on the ridge run. Structurally, this method is similar to the one described above, it differs only in the installation of a ridge beam. This design is quite reliable, but not suitable in all cases, since the ridge beam often requires the installation of additional support beams, and this reduces the usability of the attic. This method allows you to mount each pair of rafter legs in place, without the use of templates and preliminary preparation. The upper edge of the rafter leg rests on the ridge beam, and the lower edge rests on the Mauerlat.

- Mounting on the ridge run with an overlap. This method is similar to the second of those described, only the upper joint of the rafter legs is overlapped. In this case, the rafters in the upper part are not in contact with the ends, but with the sides. Bolts or studs with washers are used as a fastener.

Rafter system repair

During the operation of the house, a situation may arise when it will be necessary to repair the rafters.

Since destruction roof truss system threatens with serious consequences, it is advisable to regularly monitor the condition of the elements and, if any problems are found, take urgent measures.

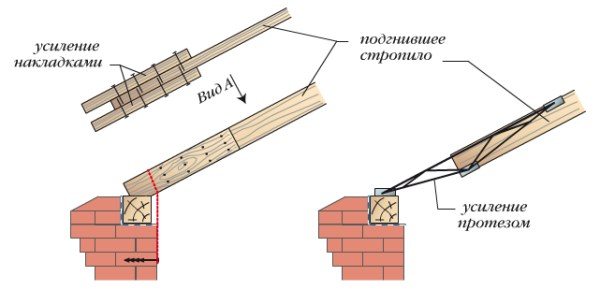

If it is found that the end of the rafter leg, which rests on the Mauerlat, has begun to rot, then proceed as follows:

- A log is laid on the attic floor, which should rest on 2-3 beams.

- Braces are installed under the repaired rafter leg with an emphasis on the log. The distance from the extreme brace to the rotten place should be at least 20 cm.

- The damaged area is sawn out, a pre-prepared liner is installed in its place.

If wood decay is found in the middle of the rafter leg, then to reinforce the structure on both sides of the damaged part, linings made of boards, the thickness of which is 50-60 mm, are nailed.

Nails are driven into the undamaged part of the rafter along the edges of the overlays.

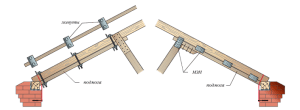

If the Mauerlat is damaged by rot, then with a small length of the affected area, it is recommended to install struts, to which a rafter leg is attached with brackets. The struts are installed with support on the Mauerlat, attached to its intact part.

If the Mauerlat is damaged for a considerable length, then an overlay of boards must be nailed to the rafter leg, which will be reinforced in a new Mauerlat, installed additionally, slightly lower than the damaged one. Strengthen the additional Mauerlat by hammering it with pins into the wall.

If, as a result of the appearance of a crack in the rafter leg, a deflection of the roof is observed, then they act according to the following plan:

- Prepare two strong boards, one of which will serve as a wringing rack, and the second as a support for it.

- The support board is laid so that it is perpendicular to the load-bearing beams of the attic floor.

- The wringing rack is placed on the support board, bringing it under the deflection of the rafter leg;

- Between the support board and the end of the wringing rack, two wedges are hammered, placing them towards each other.

- The wedges continue to hammer until the deflection of the rafter leg is eliminated;

- Then, in place of the crack on the rafter leg, two overlays of boards are applied, the length of which is not less than a meter longer than the length of the damaged area. Fix the pads with bolts.

- After fixing the linings, the wedges are knocked out and the temporary stand and the support board are removed.

Strengthening the truss system

During roof repairs, it is sometimes necessary to strengthen the existing truss system. This may be necessary if the new roofing material is heavier than what was previously used.

For reinforcement, an increase in the main section of the rafters is undertaken by building them up with boards. The amount of build-up is determined by calculations.

The connection between the gasket and the rafter leg is made using nails. Such a simple method can be used if the cross section needs to be increased by no more than five centimeters.

conclusions

During the construction and repair of truss systems, it is extremely important to follow the technology of installation and repair work. Ignoring some points can lead to a weakening of the bearing capacity of the structure, which will adversely affect the strength of the structure.

Therefore, with a lack of experience, it is better not to carry out this work on your own, turning to professionals for help.

Did the article help you?