The truss system is equipped for laying the roofing material and ensures the strength and reliability of the roof being erected. This article describes how the installation of the rafter system is carried out and what elements (rafter leg, mauerlat, etc.) it includes.

The truss system is equipped for laying the roofing material and ensures the strength and reliability of the roof being erected. This article describes how the installation of the rafter system is carried out and what elements (rafter leg, mauerlat, etc.) it includes.

The roof is a supporting structure that performs a number of functions:

- It takes on all the loads from the outside, such as the weight of the roof itself and its elements;

- Transfers the load from the crate and the material laid on it to the internal supports and walls of the building;

- Gives the building an aesthetic appearance;

- Protects the attic from the outside world, etc.

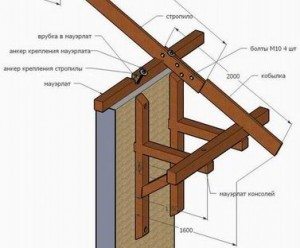

To the main carriers roof elements rafters, crate and Mauerlat can be attributed.In addition, the supporting structure includes a number of additional fasteners, such as racks, crossbars, spacers, struts, and many others.

The strength and reliability of the roof is directly affected by its supporting structure - the rafter system. Rafters are the main load-bearing part of the roof structure.

The truss system must withstand not only the weight of the roof itself, but also the snow cover on it and the pressure of wind currents, so its calculation is made taking into account such characteristics as the roofing material and the climatic conditions of the area.

Construction of the truss system

The rigidity of the roof frame is ensured by the fastening of the rafters to each other, as a result of which a strong truss system is obtained. In order to prevent the roof from being torn off by gusts of wind, the frame should be securely connected to the box of the building.

Most often, in the construction of cottages and country houses, timber truss systems are used, which are distinguished by ease of manufacture and installation.

In addition, if mistakes were made during the construction of the walls, additional processing of the rafters is quite easy - shortening, building up, trimming, etc.

When installing the rafter system, additional fasteners are also used, such as:

- screws;

- bolts;

- Nails;

- Clamps;

- Staples.

In addition to fastening, they are used to strengthen the supporting structure of the roof.Roof details connected to each other, resulting in a truss truss, which is based on triangles, which are the most rigid geometric figure.

When choosing the material from which the truss system will be made and mounted, various architectural and structural nuances of this project should be taken into account.

An important role is also played by fire and antiseptic impregnation for rafters, which has a direct impact on the duration of the roof's service life.

The rafter system, consisting of rafter legs, is the main bearing part of the roof. Installation of rafters is carried out at an angle equal to the angle of slope of the roof slopes.

The lower parts of the rafter legs are supported through the Mauerlat, which allows you to distribute the load evenly on the outer walls. The upper ends of the legs of the rafters rest on intermediate fittings or a beam under the ridge.

From there, the load is transferred to the load-bearing internal walls using a system of racks.

Types of rafters

The composition of the hanging rafters:

- Rafter leg;

- Rigel;

- Attic cover.

Elements of layered rafters:

- Mauerlat;

- Rafter leg;

- puff;

- grandmother;

- Strut.

There are two types of rafters: hanging and layered:

- Hanging rafters have only two points of extreme support (for example, on the walls of a house without the use of intermediate supports), while their legs of the rafters work in bending and compression. Hanging design rafters creates a serious bursting horizontal force transmitted to the walls. To reduce this effort, stretching is used, with the help of which the rafter legs are connected.The stretch is placed both at the base of the rafters, which then becomes a floor beam, which is the most common option for mansard roofs, and at a greater height. . An increase in the height of the extension requires an increase in its power and the reliability of its attachment to the rafters.

- The installation of layered rafters is carried out in buildings with a load-bearing middle wall or intermediate supports in the form of pillars, the ends of which rest on the outer walls, and the middle - on the supports or the inner wall. The elements of such rafters perform the function of pasterns, working only for bending. The design of layered rafters is less than the weight of hanging rafters, requires less material consumption and, accordingly, lower financial costs. Installation of layered rafters is carried out when the supports are separated from each other by no more than 6.5 m. When installing an additional support, layered rafters can cover a width of up to 12 m, and with two supports - up to 15 m.

Important: when installing a single roof structure for several spans, alternation of layered and hanging roof trusses is allowed. In places where there are no intermediate supports, hanging rafters are used, and in other places they are layered.

The legs of the rafters are usually not supported directly on the walls of the house, but on a special beam called a Mauerlat. It can be located along the entire length of the house or placed only under the feet of the rafters.

In the case of wooden structures, a beam or log is used as a mauerlat, which is the upper crown of the log house.

In the case of masonry walls, the maurlat is a bar installed flush with the inner surface of the wall, protected by a protrusion of the masonry from the outside. Between the brick and the mauerlat, it is necessary to lay a layer of waterproofing material, for example, roofing material in two layers.

Useful: in the case of a small width of the rafter legs, they may sag over time. To avoid this, a special lattice consisting of a crossbar, a rack and struts is used.

In the upper part of the rafter structure, regardless of the type of roof, a run is laid that connects the trusses or rafters.

On this run, the roof ridge is subsequently equipped. In those places where there are no load-bearing walls, the heels of the legs of the rafters rest on longitudinal beams of sufficient power - side girders.

Their dimensions depend on the actual load.

Installation of the rafter system

The angles of inclination of the roof slopes are set by the developer, taking into account the type of building and the purpose of the attic space.

At the same time, it should also be remembered that the material chosen for roofing also affects the angle of inclination:

- With roll coating, the recommended slope angle is from 8 to 18º;

- When covered with sheets of asbestos cement or roofing steel - from 14 to 60º;

- When covering the roof with tiles - from 30 to 60º.

After the load-bearing walls of the house are erected, the installation of the rafter system begins. Most often, the rafter system of a chopped wooden house differs significantly from the truss systems of houses made of bricks, foam concrete blocks and panel or frame wooden houses. These differences are quite significant even with the same shape, type and type of roof.

The main elements of the supporting structure are the crate and roof trusses. The roof itself is only the outer part of the roof, laid on a supporting structure, which consists of a batten and rafter beams.

For the manufacture of rafters, regardless of the type of construction, it is recommended to use a material with a section of 200x50 or 150x50 mm.

For the manufacture of the lathing of most coatings, boards and bars are used, the dimensions of which are 50x50 (40x40) or 150x25 (100x25) mm. The distance between the legs of the rafters is an average of 90 cm.

With a roof slope exceeding 45º, this distance is increased to 100-130 cm, and when building in areas with a large amount of snowfall, it is reduced to 60-80 cm.

For a more accurate calculation of the pitch of the rafter legs, one should take into account their cross section and the distance between adjacent supports (uprights, ridge run, struts) of the supporting structure, as well as the type of material used to cover the roof.

In case the stiffness in the plane of the legs rafters provided directly by the trusses, the resistance to wind loads arising from the side of the gable (tongue) is ensured by installing the required number of diagonal braces.

As such connections, boards 3-4 cm thick can be used, which are nailed at the base of the extreme leg of the rafter and in the middle part of the adjacent leg.

Rafter legs are the main element of the rafter system, since it is on them that the main load of the roof falls.

Therefore, it is necessary to calculate and mount how the truss system itself should be carefully and competently so that the roof lasts as long and efficiently as possible.

Did the article help you?