Choosing a roofing material for roofing is not an easy task. One of the most rational options for a pitched roof is a metal tile - the characteristics of this material make it possible to recommend it in most cases.

Choosing a roofing material for roofing is not an easy task. One of the most rational options for a pitched roof is a metal tile - the characteristics of this material make it possible to recommend it in most cases.

Metal tile. What is this material?

This roofing material is by far the most popular among professional builders and private developers.

In fact, a metal tile is a roofing material, which is sheets made of thin sheet steel, aluminum or copper, covered with a polymeric protective layer, profiled by cold pressure (Footnote 1).

For the manufacture of this material, high-tech equipment is used, which creates a profile on a steel sheet that imitates natural tiles folded in rows.

Where is metal roofing used?

When choosing a roofing material, its characteristics should be taken into account - metal tiles are an almost universal option suitable for pitched roofs of various types.

The only limitation is that it is undesirable to use metal tiles on slopes with an angle of inclination not exceeding 14 degrees.

You can use metal roofing for roofing in any climatic zone, as it tolerates both high and low temperatures.

Metal tile profiles are suitable for different objects (Footnote 2):

- Country houses.

- Garden houses.

- Shopping centers.

- Small restaurants or cafes.

- Food or non-food stalls.

- Industrial enterprises.

- Entertainment establishments.

- Medical institutions and many others.

In addition, metal tiles can be recommended for repairing an old roof.

When performing this work, it is sometimes possible to avoid dismantling the old coating. So, for example, an old roof made of roofing material can be used for additional waterproofing of the roof.

Advantages of metal tiles

The advantages and disadvantages of the material determine its properties - the metal tile is based on a sheet of steel, therefore it is a material with sufficient strength.

In addition, the following positive qualities can be distinguished:

- Light weight. So, covering an area of 1 sq. a meter weighs only about 5 kg, therefore, when erecting a rafter system, you will not need to think about strengthening, and loading and installation of the material can be done without the involvement of special equipment.

- Ease of installation. Installing metal roofing is easy. So, a team of only two people with work experience can lay up to 100 square meters of coverage per working day.

- Availability. The material itself is relatively inexpensive. Installation of metal tiles is simple, therefore, they also have a lower cost than, for example, the installation of soft tiles.

- Long coating life. High-quality metal tiles, laid in compliance with the requirements of the installation technology, serve for more than 30 years.

- Aesthetically attractive appearance of the roof. A wide variety of colors and textures allows you to embody a variety of design solutions.

The structure of the metal tile

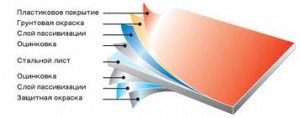

The structure of the material determines its technical characteristics - the metal tile consists of several layers, and each layer performs its own function.

The basis of the material is a steel sheet, which is zinc-coated by hot-dip galvanizing. The steel is covered on both sides with a layer of passivation, which acts as a primer, that is, it increases the degree of adhesion of materials.

On the outside, the metal tile is covered with a layer of polymeric material, and on the back - with a layer of protective paint. It is necessary to select the type of polymer coating for metal tiles, depending on the conditions in which it is planned to be used.

Types of polymers for coating metal tiles

- Polyester is the most economical solution. This coating performs well when used in a temperate climate, without extreme frost and extreme heat, if the building is not in a heavily polluted atmosphere.

- Pural is one of the most stable polymer coatings. Such material can be recommended for roofing in houses in various climatic zones.

- PVDF (polydifluoride) is the best color retention coating. A metal tile with such a coating can be used in the construction of houses in any region.

Material selection guide

It should be noted that for such a material as a metal tile, the properties are determined by the characteristics of the components used for its manufacture.

What should you pay attention to?

- metal thickness. For the manufacture of high-quality metal tiles, steel sheets with a thickness of 0.5 mm are used. If thinner steel has been used, installation will be more difficult, as such material requires more careful handling.

- Zinc coating. This coating serves to protect the coating from corrosion. As a rule, in quality samples, the zinc content is in the range of 200 grams per square meter of surface.

- Primer layer. This layer not only provides a better degree of adhesion, but also serves to protect the zinc layer from destruction under the influence of the atmosphere.

- The main attention should be paid to the choice of the polymer with which the metal tile is coated - the technical characteristics of the material are more dependent on this factor.The type of polymer determines the resistance to atmospheric influences, to ultraviolet radiation and mechanical damage.

- In addition, the thickness of the polymer layer also provides resistance to mechanical stress. Polyester is able to provide the lowest degree of protection, the most stable metal tile is obtained by applying the Plastisol or Pural coating.

- Surface structure. Manufacturers offer material with different textures. The type of texture has almost no effect on the strength and wear resistance of the material and is determined from the point of view of the design of the building. When choosing, it is worth considering such a factor as the degree of atmospheric pollution. Most often, developers choose metal tiles with a glossy or matte surface; metallic and embossed textures are also popular.

conclusions

Thus, when choosing a metal tile, one should take into account the climatic conditions of the region in which it is planned to be used.

Also, you will have to take into account the economic factor, finding a compromise between the price of the material and its durability.

Did the article help you?