Considering the possible options for arranging the roof of a private house, one should not lose sight of such as a do-it-yourself metal roof: a video on the installation of metal tiles is easy to find on the Internet, and so that you can get an idea of \u200b\u200bthe arrangement of such a roof, this article was written.

Considering the possible options for arranging the roof of a private house, one should not lose sight of such as a do-it-yourself metal roof: a video on the installation of metal tiles is easy to find on the Internet, and so that you can get an idea of \u200b\u200bthe arrangement of such a roof, this article was written.

The metal tile as a reliable, durable and fairly easy-to-use roofing material is very popular. Another advantage in favor of using metal tiles as a roofing material is a wide range of colors.

Indeed, among the variety of colors of metal tiles on the market, you can always choose a shade that will organically fit into the design of your site.

Most often, metal tiles are used in cottage construction, because they are ideal for arranging the roof of a private house.

However, when choosing a metal tile as a roofing material, it should be remembered that the minimum angle of inclination of a roof from a metal tile should be 140 (for some types of metal tiles -14) . For flatter roofs, it is better to look for another solution - or take care of arranging additional waterproofing.

What is a metal tile?

To figure out how to properly make a roof from a metal tile, we first need to study the roofing material itself. What is a modern metal tile sheet?

The base of the metal tile is a steel plate, 0.4 - 0.7 mm thick. This base is covered with a passivating aluminum zinc layer, on top of which two primer layers are applied.

Outside, a polymer layer is applied to the primed base - it is this layer that largely determines the properties of the metal tile, as well as its color. As a polymer, glossy or matte polyester, as well as plastisol, can be used.

As an additional coating, a layer of protective varnish can be applied over the polymer.

Due to this structure, metal tile sheets have a small mass, which facilitates their lifting to a height and installation - on average, 1 m2 weighs from 4.5 to 5 kg.

So, how to cover the roof with metal tiles?

Arrangement of a roof from a metal tile

Before you get started, you need to carefully study how to cover the roof with metal tiles: videos, articles in trade magazines, publications on the Internet - everything will do. And only when there are no unclear places left, you can start working.

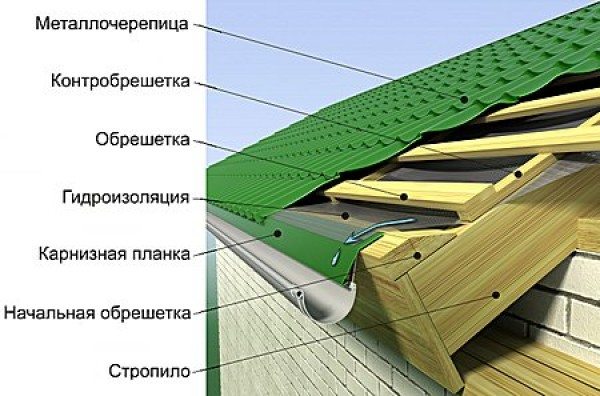

- As a preparatory stage, it is necessary to deal with the arrangement of the roof under the metal tile requires the arrangement of a waterproofing layer - it will protect your house from water even if moisture still seeps through the metal tile. We lay the waterproofing material directly on the rafters under the counter beams. It is best to use a specialized waterproofing material, laying it with an absorbent composition down (i.e. towards the room) - this will avoid the formation of condensate under the metal tile layer.

- If it is planned to insulate the roof from a metal tile, then in addition to the waterproofing material, a vapor barrier film should be used.

- To fix the waterproofing, you can use a construction stapler with galvanized staples or galvanized nails. We fix the film directly to the rafters, however, it should be remembered that in this case the distance between the rafter legs should not exceed 1.2 - 1.5 m. We fix the film, starting with the edging, and gradually moving up to the ridge.

- Lay the film strips overlapping. For convenience, most manufacturers put a black stripe on the edge of the film showing the recommended amount of overlap.

Note! When laying waterproofing, it is allowed to sag the waterproofing material between the rafters no more than 20mm.

- After the waterproofing is arranged and fixed, the roof lathing under the metal tile should be erected. To create the crate, we use 50x100mm bars treated with an antiseptic - a compound that prevents wood from rotting.

- It is also allowed to use a perforated metal profile.

- The lathing is laid over a layer of hydro- and vapor barrier materials on counter rails - 50 mm wooden blocks. In addition to protecting the waterproofing from mechanical damage, counter rails provide roof ventilation, preventing the formation of condensate.

Lathing under the metal tile

- Before you close the roof with metal tiles, you need to decide on the place to start work. If we cover a gable roof, then we begin the installation of metal tiles from one of the ends. For a hipped roof, we begin laying at the highest point of the slope, gradually moving in both directions.

- As a matter of fact, now the future roof of metal tiles is already beginning to emerge in front of us - the instruction allows laying both on the right and on the left, while if the installation starts from the left end, then we will lay each next sheet of metal tiles under the last wave of the previous one, and vice versa.

- We expose the edge of the metal tile along the cornice, and fix it with a protrusion of about 40 mm in relation to the cornice line. We fix the laid sheet of metal tile to the crate using self-tapping screws.

- The best choice of fasteners are white metal screws with an octagonal head, equipped with an additional sealing washer. Fasteners are carried out strictly perpendicular, under the transverse wave directly into the bend of the sheet. The average consumption of self-tapping screws is 7-10 pcs/m2. The most popular are self-tapping screws 4.5x25 mm and 4.5x35mm.

Note! In order to avoid damage to the material, fixing the metal tile to the beams of the crate is carried out exclusively with pre-drilling. The use of self-tapping screws with a drill without pre-drilling is not allowed.

- Longitudinal strips of sheets are fixed using self-tapping screws 4.5x19 mm with a step of one wave.

- On top of the profile wave, we install the end plate. We set the bar as evenly as possible using a stretched cord. The plank is fastened to the crate with self-tapping screws, the fastening step is 250-300mm.

- To begin with, we fix several sheets of metal tiles near the ridge. First, we align the sheets along the cornice, and only then proceed to fixing along the length. We fix the overlap of sheets of metal tiles with one self-tapping screw, which is screwed under the transverse fold on top of the wave. Docking of sheets of metal tiles should be carried out carefully, in order to avoid damage to their ends.

- If the roof has an irregular shape, then before covering the roof with metal tiles, we may need to trim several sheets. Trimming of sheets of metal is carried out using a circular saw or electric jigsaw with a metal saw installed. To avoid corrosion, the ends of the metal tile that have been trimmed are covered with paint or Kuzbasslak. It is also recommended to install the cut sheets “flush”, leading the cut line under another sheet of metal.

After all the sheets of metal tiles are laid, you can proceed to the final stage of work. Let's go to gable roof ridge and cover it with special ridge elements, fixing them with self-tapping screws through each wave.

But if you need a really high-quality metal roof, video tutorials advise you to put a layer of sealing material under the ridge, which is fixed to the crate with self-tapping screws or nails.

In this case, we lay a ridge bar on top of the seal - we will fix the ridge elements to it.

In places where our metal roofing adjoins vertical surfaces (pipes, walls) - we lay the joint strips. Under them, you may need to install additional wooden bars.

We hope that this material gives you the answer to the question - how to properly cover the roof with metal tiles. And if you approach the process of arranging the roof with all responsibility, then the result will be invariably magnificent!

Did the article help you?