A roof with a metal tile coating is a structure consisting of many layers, each of which performs a specific function. Before you cover the roof with a metal tile yourself, it is important to know how to properly mount all its elements from well-chosen materials.

A roof with a metal tile coating is a structure consisting of many layers, each of which performs a specific function. Before you cover the roof with a metal tile yourself, it is important to know how to properly mount all its elements from well-chosen materials.

What is important to consider when working

It is extremely important to carry out the entire complex of works very carefully. Especially those of them, the quality of which cannot be double-checked without dismantling the roofing elements.

For example, it is necessary that the thermal insulation is laid evenly, the joints between the vapor barrier sheets are carefully glued, and the places where it adjoins the load-bearing and wall structures are well insulated.

Negative results of incorrect metal roofing work may not appear immediately. Unfortunately, it often happens that these consequences are revealed only when the need for repair, or even a complete replacement of the roof, becomes obvious.

For example, with an illiterately made vapor barrier, condensate will begin to collect in the under-roof space. This will lower the thermal resistance of the thermal insulation and start the process of decay of the roof truss structure.

Therefore, it is very important to know how to cover the roof with metal tiles yourself.

What tools should be used

At installation of metal tiles on a gable roof it is necessary to use scissors and a hacksaw for metal, an electric drill, etc. The material often has dimensions that the customer specifies when communicating with the manufacturer's representatives. Therefore, it is most convenient when working on a specific roof.

However, it should be borne in mind that almost always there is a need to cut sheets according to their width, as well as to make technological cuts at different angles in certain places of the roof.

As a result, before covering the roof with metal tiles, purchase a hand-held electric saw with carbide teeth or another tool for cutting polymer-coated metal.

Note! It is highly not recommended to use an angle grinder (grinder) for cutting such metal. Such a tool will destroy the layers of zinc and polymer coating, as a result, the steel will begin to corrode.

Fasten sheets of material with self-tapping screws (self-tapping screws). To tighten them, you can use either a screwdriver or an electric drill that has a reverse and speed control, as well as a nozzle for screws.

Laying waterproofing and vapor barrier film

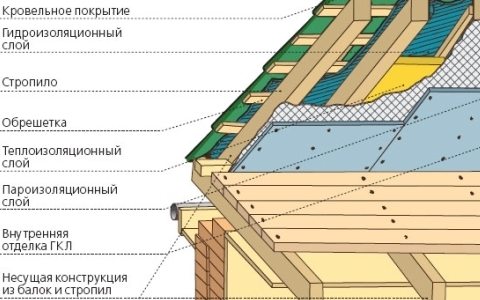

If the ventilation of the under-roof space is insufficient, it is necessary to use hydro-vapor barrier films or vapor-permeable diffusion membranes.

The use of these films will prevent the ingress of condensate from the bottom of the sheets into the thermal insulation of the roof.

The roofing material is laid out on the rafters with overlapping panels, from the bottom up. Do this with sufficient tension and fix the film with a stapler, and then, along the rafters, with clamping strips using nails.

Waterproofing is laid on the outside of the timber, and vapor barrier on the inside.

Conventional waterproofing is placed with two ventilation gaps of 3/5 cm: between the insulation and the film, as well as between it and the roofing.

Diffusion membranes are mounted directly on the thermal insulation, the ventilation gap, in this case, is only necessary between the film and the tiles.

Install the films with an overlap, at least 10 cm. Glue the joints with special adhesive tape.

Lathing installation

For the base (frame), use boards 10 cm wide and 2.5 cm thick. Please note that the first board from the eaves should be thicker - by 1.5 cm.

The gaps between the frame boards should be equal to the transverse pitch of the tile profiles - 35, 40 or 45 cm. The distance between the board that will go to the ledge and the next one, make it 5 cm less.Fix the crate to the rafters or the counter-crate with nails.

As a counter-batten, you can use bars with a section of 5 × 5 cm. Before you start assembling the frame, dry all the boards and timber well, and then soak them with antiseptic and flame retardant compounds.

The first of the boards must be fixed above all the others by the height of the wave profile of the tile. At the ridge, chimneys, valleys, etc., to strengthen the structure, make a continuous boardwalk.

How to collect coverage

Before covering the roof with metal tiles, first fasten the cornice strips to the last board of the frame. Overlap them in length by 10 cm.

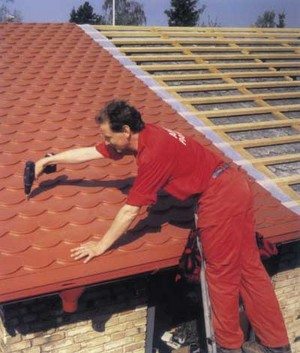

Advice! If the roof is gable, then it is most convenient to mount the sheets, starting from the left end. When the roof is hipped, the tiles are laid and fixed, starting from the highest place, while installation can be done simultaneously in both directions.

With the direction of the assembly of the coating from right to left, install each subsequent sheet under the last wave of the previous tile. The bottom edge of the covering should hang down from the eaves by 4/5 cm.

Lay the first sheet of shingles and fasten it with one screw to the frame at the ridge.

Next, install the second of the sheets so that their lower edges form a straight line. Fix the joint with a self-tapping screw under the first of the lower transverse folds of the profile wave. In this case, the screw should not enter the crate board.

If the sheets are uneven, lift the top one slightly above the bottom one. Then, slightly tilting it and moving in the direction from the bottom up, collect the folds and at the same time grab them with screws along the top of the wave under each of the transverse folds.

Having connected several sheets in this way, align their common lower edge along the eaves and fix this piece of the coating completely. Further work will go much easier, since you will find the right direction.

Additional and additional elements

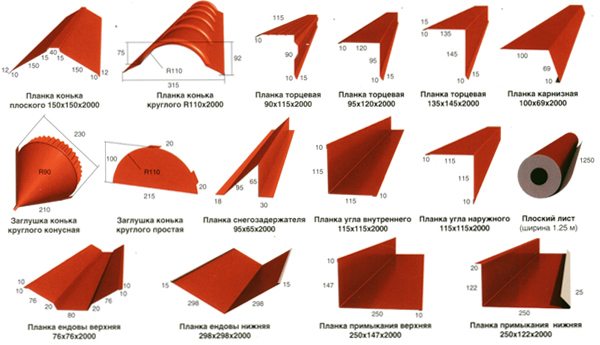

An important point in knowing how to cover the roof with metal tiles yourself is the skill of working with additional details.

- Fix the end strips from the bottom up along the gables, covering the end edges of the tiles with them. Attach them to the last wave of sheets and to the frame with self-tapping screws.

- Ridge strips are mounted only if all roofing sheets, as well as end strips, have already been supplied and the sealant has been fixed (as necessary). Fasten the ridge strips to the tiles with screws at the top point of every second profile wave.

- Before installation work on the valley (the inner junction of the slopes), make a solid boardwalk there. Attach a smooth metal sheet 1.25m wide to it, bending it in the middle. Bend the edges of the metal up 1 / 1.5 cm in width. Next, attach it to the flooring. After the installation of the tiles, at the joints of the sheets, in the direction from the bottom up, the valley strips are fixed with screws into the crests of the wave.

- To prevent snow from falling in selected places, for example: above the entrance groups, near the garage, you can install corner snow stoppers with your own hands, which consist of a fixation corner and a snow stop bar. This element is installed under the second transverse pattern from the beginning of the eaves, in other words, at a distance of about 35 cm from it. The fastening bracket is mounted on the profile under the plank and fixed together with it through the tiles to the frame with a long self-tapping screw.The bottom of the snow-retaining strip is fixed to the tiles at the upper points of every second of the waves with screws of the usual size.

- To seal the junctions of the roof slopes to the walls, strips for seams and joints are used. They are fixed to the upper points of the wave of coating sheets, and on the side - to the adjoining wall. It is also necessary to additionally seal the joints between the planks and walls with silicone sealant.

- When installing the spillway system, the assembly of all its elements: gutters, hooks and pipes must be carried out according to the manufacturer's instructions.

Note! Using the drainage system, it is necessary to fix the hooks on the frame boards (near the eaves) that fix the gutters even before installing the coating sheets.

In order for you to understand more about the installation process, we have placed material on this page: how to cover the roof with metal tiles: video.

Did the article help you?