If you decide to carry out the laying of metal tiles yourself, then this review is for you. In the article you will find step-by-step instructions describing each action. You just have to follow all the recommendations, and after 1-2 days your metal roof will be ready.

- Stages of work

- Stage 1 - necessary materials and tools

- Stage 2 - measurements of the structure and installation of waterproofing

- Stage 3 - installation of the crate

- Stage 4 - fastening the cornice strip and brackets of the drainage system

- Stage 5 - fixing the roofing material

- Stage 6 - installation of additional elements

- Conclusion

Stages of work

The device of a roof from a metal tile can be divided into the following stages:

- Preparation of materials and tools;

- Roof measurements and fastening of the waterproofing layer;

- Installation of the crate;

- Installing the cornice strip and gutter brackets systems;

- Fastening sheets of metal;

- Installation of skates and pediment strips.

With all its advantages, the metal tile is very demanding on the observance of the installation technology.

Stage 1 - necessary materials and tools

First you need to collect everything you need, the full list is indicated in the table.

| Material | Description |

| metal tile | This is the main material, the quality of which is of great importance. Choose products of well-known companies that have proven themselves in the market. If the slope length is less than 6 meters, then the surface is closed in one row, if more than 6 meters, then it is better to lay two rows |

| Accessories | On any roof, a ridge element, a wind board and a cornice strip are used. It can also be used to connect to the pipe, as well as valleys in the presence of bends on the roof |

| roofing membrane | Special material does not let water inside, but does not prevent the evaporation of moisture from the insulation and wood. Sold in rolls of 70-75 square meters |

| Lathing material | Available in thicknesses from 30 to 50 mm and widths from 40 to 60 mm. A board 100 mm wide and 32 mm thick will be laid on top of it.Choose dry material to avoid warping and cracking |

| fasteners | The waterproofing is fastened with brackets, the elements of the crate with self-tapping screws. For roofing, special self-tapping screws are used in the color of the metal tile with special rubber gaskets under the washer. They have a drill tip that allows you to fix the coating without drilling. |

As for the tool, we need the following list:

- Screwdriver for tightening self-tapping screws. The kit should include nozzles for both standard fasteners and roofing fasteners, do not lose sight of this nuance;

- For cutting wooden elements you need a hacksaw tree or power tool;

- Cutting metal tiles and components is worth special scissors. It can be either manual or electric;

- To take measurements and markup, you need a tape measure and a marker, as well as a long rail or level;

- I also recommend getting a can of paint in the same color as the finish. It is usually sold in the same place as the metal tile. If you suddenly scratch the surface, then quickly eliminate the flaw.

In no case do not use a grinder to cut metal tiles. In the process of work, the ends of the metal overheat very much and after a year or two they begin to rust.

Stage 2 - measurements of the structure and installation of waterproofing

If everything you need is at hand and the rafter system has been erected, you can proceed to the initial work:

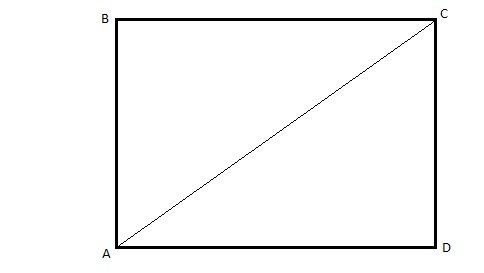

- Before covering the roof, you should check its dimensions. You must measure the length and width of each side, and then check the diagonals. If they are not the same, then you need to eliminate the skew;

- The waterproofing material is cut in such a way that when laying it protrudes 20 cm on the sides. That is, you need to cut a piece that will be 40 cm more than the width of the ramp. The film is easily cut with scissors or a construction knife;

- Laying is carried out from the lower edge of the truss system. The material is gradually rolled out and fixed on the elements using a construction stapler. The sag of the film should not be more than 2 cm. The work is quite fast and simple, the main thing is to position the canvas evenly and securely fix it;

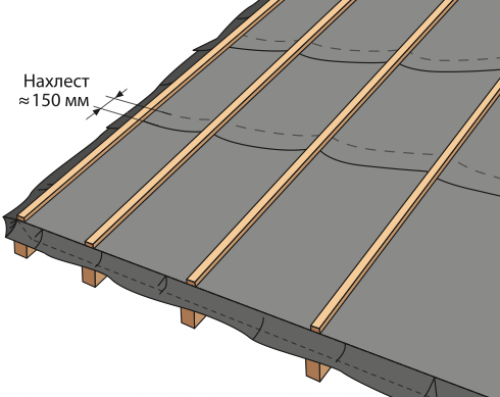

- The next row is positioned so that the overlap is 150 mm. This will provide reliable protection against moisture. At the joints, fix the material with a stapler especially carefully.

Stage 3 - installation of the crate

This part of the work consists of the following:

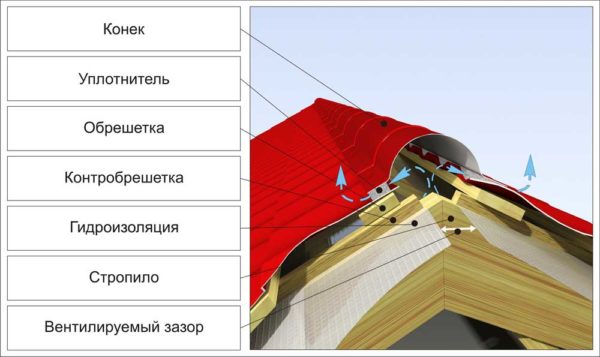

- After fixing the membrane, a bar 3-5 cm thick is installed on top of the rafters. It is fixed with self-tapping screws twice the thickness of the elements. The counter rail (as this element is also called) will serve as an additional fastener for the film and create a ventilation gap under the roofing;

- The bar can be attached simultaneously with the film - they laid one row, nailed the bar, and so on, until the entire surface is covered;

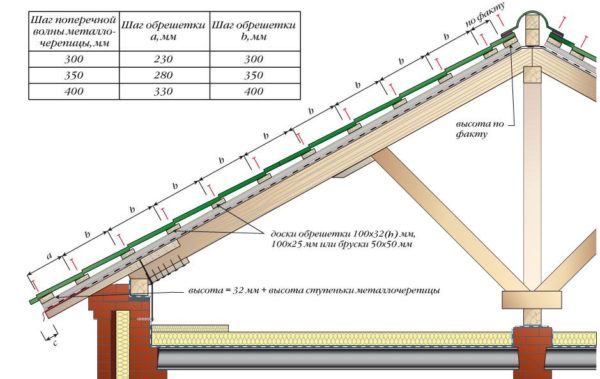

- On top of the bars it is necessary to fix a board with a thickness of 32 mm. A solid crate for metal tiles is not needed, the spacing of the elements is 300 or 350 mm, depending on the type of product. In this case, the first row is always located at a smaller distance. To make it easier for you to understand, below is a diagram in which there are all the required distances depending on the transverse step of the waves;

The bottom board of the lathing is always thicker than the rest by the height of the wave of the roofing material, usually 10-15 mm. Therefore, the first row is made from a 40 mm board.

- The board is nailed over the entire area, the ends can not be strongly aligned. It is easier to cut them off later, then you will get a straight line with minimal time;

- Around the chimneys, as well as on the valleys and near the ridge, a continuous crate 30-40 cm wide is made. This is necessary to strengthen the surface;

- Lastly, boards should be nailed to the ends of the gables. This will increase the convenience of installing a metal tile with your own hands, since you will have a clear line along which it will not be difficult to align the element.

Stage 4 - fastening the cornice strip and brackets of the drainage system

When figuring out how to properly cover the roof with a metal tile with their own hands, many people miss this particular part of the work. Then you have to contrive and get out of the situation as it turns out.

But you can do everything right without any problems:

- First of all, a frontal board is attached to the ends of the rafters. It allows you to align the line and create a strong support for the end elements. The board is screwed with self-tapping screws or nailed with galvanized nails;

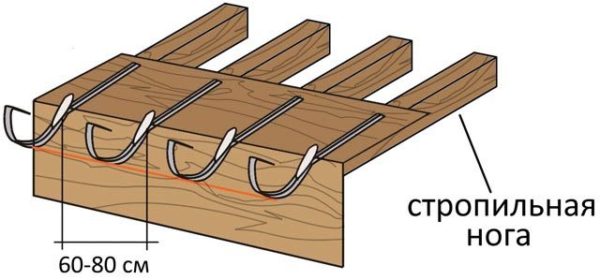

- Further, gutter brackets are attached to the bottom board of the crate. They are located in increments of 60-80 cm and are fixed with nails or self-tapping screws. Everything is simple here, the main thing is to purchase fasteners in advance to put it in place;

- A cornice strip is located on top of the brackets and is fixed with nails or self-tapping screws. The fastener pitch is 10 cm, it is located in a zigzag pattern: first from above, then from below. At the joints, the strips must overlap each other by at least 50 mm;

- If you have valleys, then you need to fix the lower part after the cornice element. It is laid along the bend of the roof and cut to the length you need, if there are connections, then make an overlap of at least 150 mm. After that, the element is fixed. Remember that the valley must necessarily lie on top of the cornice strip, and not vice versa.

Stage 5 - fixing the roofing material

Now let's figure out how to cover the roof with a metal tile with your own hands.

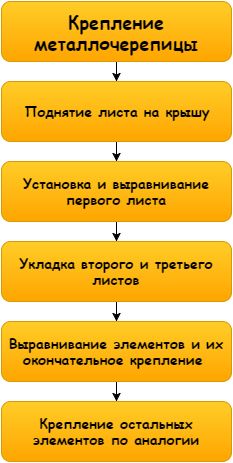

The instruction for the work looks like this:

- First you need to raise the sheet to the roof. This can be done very simply: put two boards like a sled, tie the element with a rope and tighten it up. It is possible to build a frame into which the sheet is inserted and which climbs on the same sled, this option is good for high roofs and large sheets;

- If the slope is very steep, then several stairs should be made that will be fixed on the ridge. It will be much safer to work with them;

- The first sheet is aligned along the end and fastened with one self-tapping screw to the upper part of the crate. It should be located approximately in the middle and should not be twisted too much. The element must be free to rotate in both directions. Remember that the sheet should not extend below the overhang by more than 5 cm;

- The second sheet is placed next to it and starts from above or below (depending on which side you started work on). The elements are fastened together with 1-2 self-tapping screws at the connection. Moreover, the screws should not be screwed into the crate. They are only needed to connect the parts;

- In the same way, the third sheet is placed and fastened with the second. After that, you need to align our three elements and you can proceed to their fastening. To make it easier for you to understand, the layout of the roofing screws is shown below. Fasteners go along the edge in each wave, and then they are staggered;

- Further work is made easier, each subsequent sheet is placed and fixed on the surface. Covering the roof with metal tiles is quite fast due to the large size of the sheets.

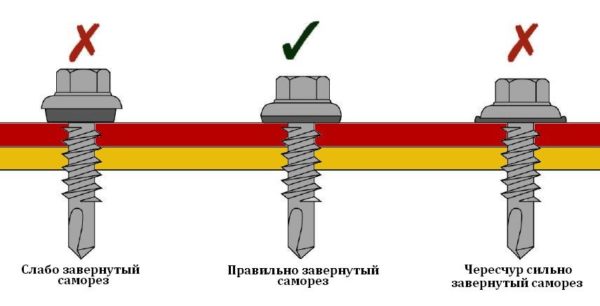

Self-tapping screws should be screwed in correctly, if they are placed awry, then water will get into the hole.It is also important to tighten them with the right amount of force so that the rubber gasket fits snugly, but does not crush.

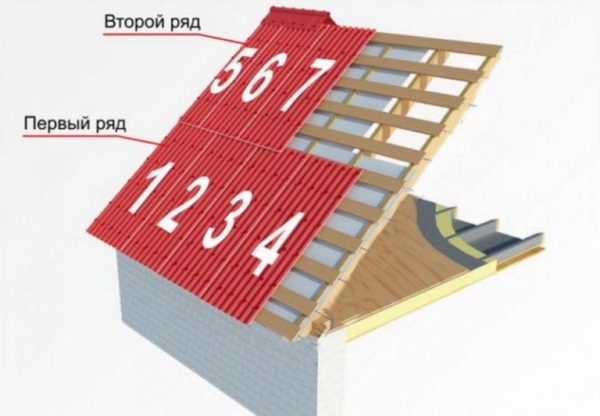

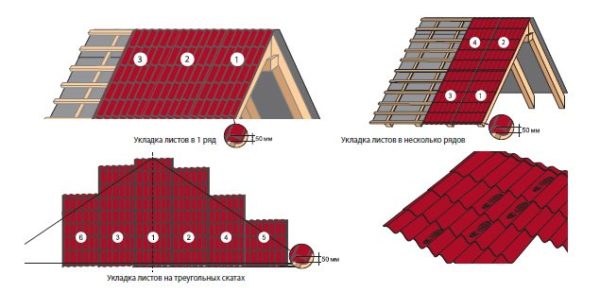

If your coating will be located in two rows, then the installation of metal tiles will take place a little differently:

- The bottom row is laid first, connect 2-3 sheets, align with the overhang and fasten to the crate. Then you can drive the first row, or you can proceed to the second, and work gradually. It all depends on you. The diagram below shows the correct stacking sequence;

- The overlap on vertical slopes should be 50 mm, but there everything is combined along the ledges and it is impossible to confuse something. Below is a diagram of laying the material on triangular slopes. It also shows which parts of the material you can step on so as not to damage it when moving along the roof.

After finishing work, inspect the surface, if there are scratches and scuffs on it, then they must be immediately painted over with paint. It is better to pre-degrease the places of tinting.

Stage 6 - installation of additional elements

Here the workflow is carried out in the following order:

- End strips are purchased in the color of the main coating. This element provides effective protection against moisture at the edges of the roof, where water is blown in by the wind. That is why this element is also called a wind bar;

- Fastening is carried out using self-tapping screws, which are screwed in both from the side and from above in increments of 50 cm. From above, you need to tighten the fasteners at the junction of the plank to the roofing material;

- The overlap at the joints should be at least 100 mm, the joint is reinforced with a self-tapping screw and coated with sealant for reliability;

- The ridge of a metal tile can have a different shape. It is made of tin in the same color as the base material.. Below is a design diagram, from which it is clear that this element serves both to protect against moisture and to ventilate the under-roof space;

- A sealing foam tape is glued along the ridge line, it is located at the width of the protrusions. It is easier to try on the element and mark the location of the seal and then work;

- Installation of the ridge starts from the edge of the roof, it is placed on the wind bar so that the edge protrudes 20 mm. Fastening is carried out with roofing screws 70 mm long, they are located at a distance of 50 cm from each other;

- The overlap on the joints must be at least 100 mm, semicircular options are joined along the stamping line.

Conclusion

From this review, you learned all the nuances of installing metal tiles. Now you can do the work yourself and save a lot of money. Watch the video of the workflow to understand it even better, and if you have questions, feel free to write them in the comments below the review.

Did the article help you?