Today we will try to tell you in detail what the installation of a roof with a metal tile is. In addition, we will tell you which roofing technology with metal tiles is recommended by manufacturers.

Today we will try to tell you in detail what the installation of a roof with a metal tile is. In addition, we will tell you which roofing technology with metal tiles is recommended by manufacturers.

Briefly about roofing material

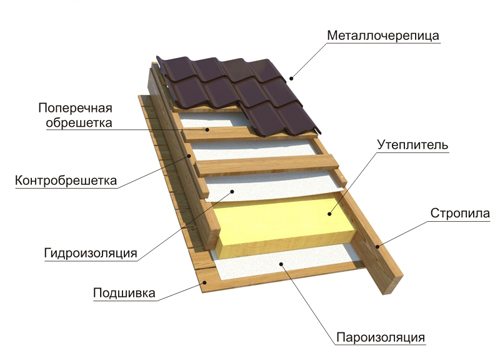

Before you start laying metal tiles, remember the basic concepts, as well as what the roofing "pie" consists of. This name was given to him because of the high content of layers that perform various functions.

Only thanks to this design, with the right selection of materials, as well as installation work, you will be provided with a durable and strong roof.

It must be clearly understood that the roof has a complex structure, during the construction of which it is necessary to follow some recommendations when covering the roof with metal tiles offered by the manufacturer.

The laying of metal tiles must be kept under constant control, since with poor-quality work, the consequences do not appear immediately.

For example, poor-quality laying of hydro and vapor barrier can lead to accumulation of condensate, change in properties roof insulation, rotting wooden components of the structure.

Do not forget that, only if the basic rules for laying metal tiles are observed, you can build a durable and strong roof. And with this you will be helped by the correct technology of a roof from a metal tile.

Before starting any work related to the installation of a roof on the roof of a building, you must understand that the roof is a complex structure and for any type of work it is imperative to follow the recommendations of the manufacturers of roofing material, in our case, metal tiles.

- Firstly, it is necessary to understand that the technology of metal roofing is possible with a roof slope of more than 12 degrees, otherwise, the roof will not perform its functions of removing precipitation from the roof of the building, and this will lead to a critical reduction in the life of the roof.

- Secondly, the eternal pitfall in any installation work is the strict observance of all the rules for the installation of metal tiles, and in no case violate the sequence of operations specified by the manufacturer.When the technology of installation of a metal tile roof is violated, this leads to the failure of both the metal tile itself and the crate, as a result of which it can lead to the destruction of the roof and additional investment.

What is a metal tile?

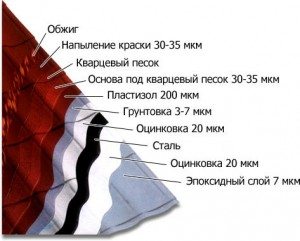

A metal tile is one of the inexpensive and at the same time practical and economical roofing materials, which are a metal base that has both a zinc coating on both sides and a synthetic coating on the upper front side.

Among the advantages of metal tiles are:

- resistance to corrosion as a result of the influence of precipitation;

- light weight (3.84.8 kg / m2); - long service life (3050 years);

- wide choice of colors;

- resistance to temperature changes.

Corrosion resistance is ensured by coating the metal base with zinc. The zinc layer varies depending on climatic conditions and is allowed within 140275 g/m2.

Light weight is achieved by reducing the thickness of the steel sheet. So the minimum thickness reaches 0.4 mm.

However, manufacturers recommend: in order not to deform the roof units made of metal tiles, the material during installation must be used with a thickness of at least 0.5 mm.

This characteristic is very important when choosing a material, since with an increase in the thickness of the material, its strength increases, but at the same time the specific gravity increases, which entails the strengthening of the rafters and, if necessary, the foundation of the building.

The maximum thickness of a metal tile sheet is 1 mm.

A choice of colors from 26 colors of polymer coating, which will help emphasize the individuality of your building decisions. Also, this coating has not only aesthetic, but also additional protective functions, as it is protected from ultraviolet, chemical and mechanical influences.

Installation instructions for metal tiles

- Installation of a waterproofing layer. This is necessary to prevent condensation on the bottom surface of the metal sheet as a result of the difference in ambient temperatures and fumes rising from the inside of the house.

- Installation roof insulation. We install thermal insulation between the rafters to provide both sound insulation and heat preservation inside the building.

- Installation of vapor barrier. On the inner surface of the rafters, we overlap the panel of the vapor barrier film, followed by a hermetic connection with adhesive tape.

- Crate. We carry out the crate with a bar of 50x50 mm. The distance between the boards during the lathing varies between 300-400 mm, depending on the choice of metal tiles.

Tip! We also draw your attention to the distance between the rails. With an increase, when choosing a metal tile, weight, the distance between the slats decreases. So for a metal tile with a thickness of 50 mm, it is necessary to observe the distance between the rails of 300 mm, and with a thickness of 80 mm, the distance will be 270 mm, respectively.

Falling beams must be nailed onto the rafter over the waterproofing film in the direction from the ridge to the eaves. Next, the boards of the crate are nailed with strict observance of the necessary distances.

This is important to prevent subsequent undesirable deformation of the metal tile and preserve its properties. The first board of the crate must be taken 1015 mm more than the others.

The next step is to cover the roof with metal tiles.

Initially, you need to make sure that there are no distortions of the roof planes, as this affects the visibility of the joints during the assembly of the metal tile.

Prior to the installation of the roofing sheets, a cornice strip is installed, under which a triangular sealant is attached, which provides ventilation of the attic due to its joints. After that, the V-shaped parts of the internal joint-valley are installed.

The roofing sheets are lifted up like on rails using 2 bars that are set at an angle. The person who is at the bottom of the sheet feeder must necessarily wear gloves and a helmet in order to avoid injury more likely.

To your attention! It should be remembered that the edges of the tiles are quite sharp and at high speed cut everything like scissors. Roofing from a metal tile - the technology recommends starting the laying of a metal tile from the eaves, directing it from left to right, or from right to left.

If laying is done on the left, then the procedure is as follows: the first two bottom sheets are placed, which are joined together with screws.

After that, the first sheet is laid to the frontal board, certainly under the wave with a step through one wave. The following sheets are attached in a checkerboard pattern.

The main rules of fastening: a roof made of metal tiles - the nodes of which are necessarily fastened with screws with a rubber gasket, are screwed under the wave a little away from the crest of the wave.

It is undesirable to tighten the screw, but you should not make a weak fastening either, since in both cases this leads to a roof leak. Holes for chimneys and other holes are recommended to be made on the ground.

First, the dimensions of the chimney are outlined on the roofing sheet, after which a hole of the proper shape is cut out with nibbling scissors or vibrating shears (the use of a grinder is prohibited!)

Measurements, production and installation of planks

Planks can be purchased in a standard form from the factory, or you can order special ones that will meet the dimensions of the ridge, end plank, frontal board.

The installation of the ridge is carried out with screws with an interval of 10 cm. In order to prevent moisture from getting under the ridge, it is recommended to put strips of sealant (universal rectangular or wavy), while leaving a gap between them.

After reading this article to the end, you will understand that, despite the complexity of metal roofing technology, it is quite possible to master the installation with your own hands, but you need to do the work according to step-by-step instructions.

Did the article help you?