Many developers choose metal tiles as the material for roofing. And how many sheets do you need to purchase to cover the roof? The answer to this question can be obtained by calculating the metal tile.

Many developers choose metal tiles as the material for roofing. And how many sheets do you need to purchase to cover the roof? The answer to this question can be obtained by calculating the metal tile.

Much has been written about the advantages of metal roofing. This is a material that allows you to create very reliable and beautiful roofing. Due to its qualities, metal tiles are very popular today, most developers prefer to cover the roof with this material.

But how many sheets of metal tiles do you need to buy to cover the roof?

After all, no one wants to face the problem that during installation it turns out that there were not enough sheets, or after it turns out that there are a lot of surpluses left.

To avoid these problems, it is worth knowing how to calculate the metal tile?

It would seem that this is an easy task. It is enough to calculate the area of \u200b\u200bthe roof and you're done!

In fact, everything is not so simple. In any sales company you will be given a slightly different calculation - metal tiles, as well as any roofing material, should be purchased with a margin, since, firstly, you need to take into account that the sheets are overlapped, and, secondly, part of the material will definitely go to waste.

What to consider when making calculations?

The first step is to measure the roof. You can do this on your own, but ideally, it would be better to invite a measurer who has experience in carrying out such work.

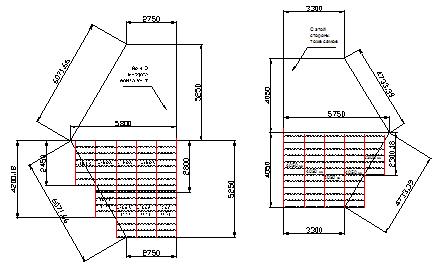

That is, before calculating the metal tile, we need to find out the dimensions of each roof slope.

It will be more difficult to make calculations, the more complex the roof has. The simplest option is a single or gable roof with rectangular slopes.

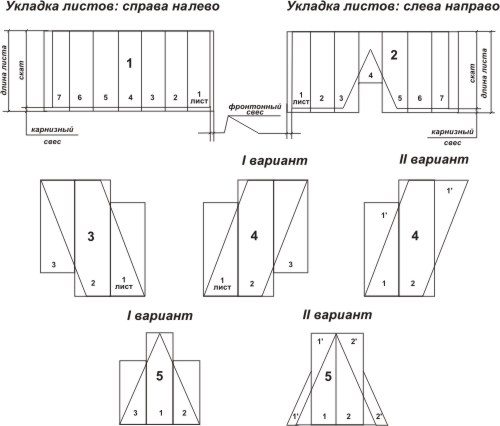

When calculating the amount of metal tiles, you should remember about the features of this material. The fact is that, unlike other sheet materials (metal profiles, slate, etc.), metal tiles are not symmetrical.

That is, the sheets cannot be placed on the roof as you like, you have to orient them in one direction.

In other words, each sheet of metal tile has its own "top" and "bottom" and it is impossible to turn them over or confuse directions during laying.This circumstance significantly increases the consumption of material when covering roofs of complex shape, with a large number of internal and external corners (valleys).

When installing a roof on such roofs, a significant amount of waste will inevitably arise, which is far from always possible to rationally use.

Another point that must be taken into account when calculating is that the material Cloudy metal tile has a profile (waves) that imitate a tile coating.

And this profile has a very definite step. As a rule, the wave pitch is a stable value that most manufacturers adhere to, and it is 350 mm.

The standard, as a rule, is the width of the sheet. Only one should distinguish between such concepts as real width and effective size.

We are interested in the effective or useful size that the metal tile has - the calculation is made taking into account this parameter, and not the actual width of the sheet.

For example: Monterrey metal tile has a real sheet width of 1.18 meters, and Tacotta metal tile - 1.19. The useful width of these samples will be equal to 1.1 meters. The remaining parts of the sheet will be used for overlapping when laying.

The length of a metal tile sheet depends on the manufacturer. So, the companies Metalo Profile and Grand Line offer the production of material of the required length to order. When purchasing Tacotta metal tiles, the length of the sheets will be standard.

Calculation steps

In order to calculate the amount of metal tiles, we need:

- Count the number of rows on the slope;

- Calculate how many sheets will be in a row and what will be their length.

Let's talk about these stages in more detail.

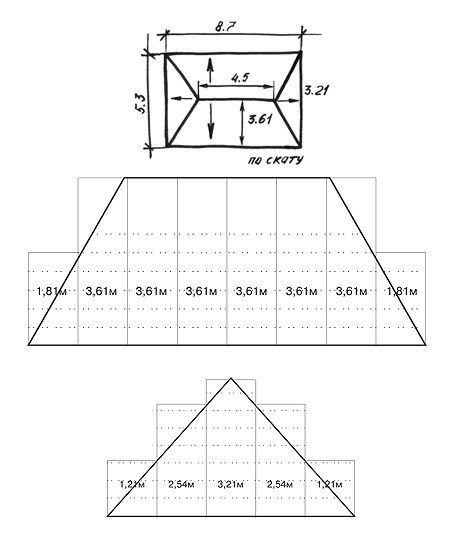

We count the number of rows on the slope of the house. This is a fairly easy job. It is necessary to measure the length of the slope (along the cornice or ridge) and divide it by the working width of the metal tile sheet, rounding the resulting value up.

Example: Let's say the slope length is 6 meters, the working width of a standard sheet of metal is 1.1 meters, therefore, we need six rows of metal tiles:

6m: 1, 1m = 5.4545; round up the value, we get 6 sheets.

We count how many sheets will be in a row and what is their length

As already mentioned, a number of manufacturers offer to make metal tiles of a given length. We will tell you how to calculate the number of metal tiles and the length of the sheet in order to place an order correctly.

First, let's calculate the total length of the sheets. It is not difficult to do this, it is enough to add up the length of the slope (the distance from the eaves to the ridge), the length of the overhang of the eaves (as a rule, this value is 0.05 meters) and the length of the vertical overlap of the sheets. .

If one sheet is laid along the length of the roof, then the last summand of the sum will be equal to zero. If there are several sheets, then the value of each overlap is 0.15 meters.

The ability to order sheets of metal of a certain length allows you to reduce the amount of waste, compared with the installation of roofing from sheets of standard length.

The maximum length of a sheet is 8 meters, however, it is extremely difficult to mount and transport material of this length. Therefore, it is recommended to order sheets whose length does not exceed 4-4.5 meters.

What is the benefit of such a decision?

- Ease of loading and loading metal tiles, such as Andalusia;

- The ability to use conventional transport for transportation (no need to look for a car that can deliver a long load);

- It is easier to ensure normal storage conditions (it is undesirable to store metal tiles in the open air);

- Less risk of damaging or deforming the sheet while lifting it to the roof;

- With a moderate length of the sheet, the coefficient of change in linear dimensions under temperature effects does not gain large values. That is, there is no risk of strong tension of the metal and tearing of fasteners.

It should be remembered that there is such a thing as "forbidden sheet length." The fact is that it is undesirable to cut the sheet along the length in the area of \u200b\u200bthe wave drop on the crane, as this is fraught with the occurrence of deformations that will lead to installation difficulties. Therefore, sheet cutting is carried out only in a certain place of the profile.

What sheet lengths are classified as "forbidden"

| 7,03-7,13 | 5,63-5,73 | 4,23-4,33 | 2,83-2,93 | 1,43-1,53 |

| 6,68-6,78 | 5,28-5,38 | 3,88-3,98 | 2,48-2,58 | 1,08-1,18 |

| 6,34-6,43 | 4,93-5,03 | 3,53-3,63 | 2,13-2,23 | 0,71-0,84 |

| 5,98-6,08 | 4,58-4,68 | 3,18-3,28 | 1,78-1,88 | 0,51-0,69 |

The table can be used when calculating the consumption of metal tiles with a wave pitch of 350 mm, the sheet lengths in the table are given in meters

Let's consider how to calculate a metal tile using a specific example.

Example: The length of the slope from the ridge to the eaves is 6.1 meters, that is, laying one sheet is problematic.

We accept that there will be two sheets in a row, therefore, the length of the slope, calculated according to the above formula, will be:

6.1m + 0.05m + 0.15m = 6.3m.

The length of the bottom sheet must be a multiple of the wave pitch Viking metal tiles (our example uses 0.35 m pitch material) plus the amount of overlap (0.15 m).

Therefore, the length of the bottom sheet can be:

0.15 + 2*0.35 = 0.85 m or

0.15 + 3*0.35 = 1.2 m or

0.15+ 4*0.35 = 1.55m etc.

Thus, the possible lengths of the bottom sheet, in addition to those given above, are 1.9; 2.25; 2.95; 3.3 etc.

Now let's calculate the average length of the slope. To do this, the total length (calculated above) is divided by 2:

6.3m : 2 = 3.15m

We choose from the calculated values of the length of the bottom sheet closest to the average. In our case, this is 3.3 m or 2.95 m. Subtract the selected value from the total length of the sheet and get the length of the top sheet.

6.3m - 3.3m = 3.0m

We check according to the table whether the calculated value is in the "forbidden" ones. In our case, everything is fine.

If it turns out that the calculated value belongs to the “forbidden” category, we try other options for the length of the bottom sheet (for example, 2.95 m) until we find the desired number.

So, we calculated that two sheets should be laid along the length of our slope. The lower one has a length of 3.3 meters, the upper one = 3.0 meters.

A metal tile calculator can help you make approximate calculations.

This service is available on many websites of companies selling roofing material. However, such calculations will only provide approximate data.

Conclusion

It is quite difficult to make accurate calculations of the number of metal tiles. If for a roof of a simple form this can be done independently, then for the calculation of roofs of a complex profile it is better to call professional measurers.

Did the article help you?