In Russia, largely due to the ease of installation, the optimal ratio of "quality / price" and proven operating properties, the most common roof is made of metal. Not the last place in this list is given to the excellent decorative properties of metal tiles. In our article, we will talk about the fact that there are not only standard sizes of metal tiles, it is quite possible to order or purchase roofing sheets according to individual sizes.

In Russia, largely due to the ease of installation, the optimal ratio of "quality / price" and proven operating properties, the most common roof is made of metal. Not the last place in this list is given to the excellent decorative properties of metal tiles. In our article, we will talk about the fact that there are not only standard sizes of metal tiles, it is quite possible to order or purchase roofing sheets according to individual sizes.

Types of metal roofing

A metal tile is a galvanized sheet that imitates natural tiles, which is coated with polymeric materials.The thickness of the steel ranges from 0.4 mm to 0.6 mm.

Like any roof metal roofing must protect the roof from climatic and atmospheric influences, mechanical damage.

On the Russian market, metal tiles are represented by a wide range. But the most famous brands, no doubt, are the manufacturers of Sweden and Finland.

Modern classification of metal tiles depending on the type of its coating:

- Plastisol.

- Pural.

- Polyester.

- Matte polyester.

The above coatings have an individual size of metal tiles, differentiated by steel thickness, quality indicators and, accordingly, cost.

Consider the main characteristics of each coating:

- Polyester. The minimum coating thickness is 25 microns. Gloss index - 5 units. Operation at the maximum temperature of +100 degrees is allowed. The processing temperature is at least 0 degrees. The covering has sufficient resistance to influence of an ultraviolet, well resists dirt sticking. But it does not tolerate mechanical damage.

- Matte polyester. Roofing 35 microns thick. Weak gloss index of only 1 point on the gloss scale. Operation at a temperature of +100 degrees is possible. The coating is moderately resistant to mechanical damage, but tolerates the effects of climatic factors well. Medium resistance to dirt sticking.

- Pural. Coating thickness - 50 microns. Gloss index - 4 balls. Operation at a maximum temperature of +120 degrees. Processing temperature - minus 15 degrees. Medium resistance to mechanical damage. It tolerates ultraviolet radiation well.

- Plastisol.The maximum thickness of the metal tile is 200 microns. The coating perfectly resists many mechanical damages and tolerates exposure to ultraviolet radiation quite well. Operating temperature maximum + 80 degrees Celsius. Processing at a minimum temperature of + 10 degrees.

Features of laying metal tiles

The width of the metal tile is basically standard, since most manufacturers use rolled steel of the same width.

But still, each manufacturer has an individual geometry. That is, such characteristics as the height of the profile step, the height of the wave, its shape, the distance between the crests.

Metal roofing technology depends on its technical dimensions and is produced with certain overlaps: transverse and longitudinal.

It is important to know: the same cost per linear meter, depending on the technical dimensions, will allow you to get a completely different amount of useful area of \u200b\u200bthe roofing material.

First of all, it depends on such parameters as: the width of the metal tile sheet, the ratio of the sheet area (overlap with neighboring sheets) and the usable area, it is she who performs the task of covering the roof.

A little advice: you can reduce the cost of useless area if you reduce the number of transverse overlaps. To do this, the length of the metal tile should have maximum performance.

But, at the same time, most experts do not recommend being tempted by the large length of the metal tile.Since the tightness of the roof and the quality of its installation largely depends on the transportation, storage, transfer and lifting of sheets on the roof.

The length of the sheet + metal tile is a very important category that must always be taken into account. So, when covering a roof with non-rectangular slopes, it is not profitable to purchase long sheets, since they will need to be cut.

And for this you need a special tool. And the quality of manual cutting is much lower than production cutting. Including: longitudinal overlaps in this case cannot be avoided.

Hence the conclusion: the consumer pays for a large area of coverage for the roof. That is, the working width of a metal tile depends not only on its technical parameters, but even on the manufacturing country.

A little advice: in order to minimize your waste, buy metal tiles of the optimal length with minimal overlaps.

The size of a metal tile sheet, depending on a certain length, is commonly called a "measured sheet". As a rule, these sheets consist of a different number of modules (1,3,6,10).

This feature of the metal tile contributes to the fact that it is possible to minimize the number of joints by streamlining the alternation of seams.

A word of advice: use the modular system when installing sheets on the roof. This will allow you to beautifully arrange the sheets.

Although with a well-executed installation of metal tiles, horizontal joints are absolutely not visible.

Some myths about metal roofing

The dimensions of a metal tile sheet are usually indicated by the manufacturer. A conscientious dealer is also obliged to indicate the effective useful dimensions.

But do not neglect the geometric dimensions, since from the extreme ends of the roof, the extreme sheets are laid without overlaps - “uncovered”.

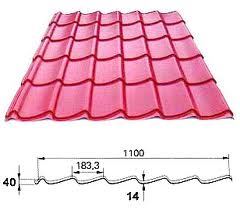

The dimensions of the sheets of metal tiles also depend on the nature of the wave, its parameters, and the pitch. Many manufacturers maintain a step of standard sizes.

So, along the slope (vertically) the length of one wave is 350 mm, across the slope (horizontally) - 185 mm.

Recall that the metal tile is not a symmetrical material, unlike corrugated board or slate. That is, you need to know such a category as: metal tile size.

It is important to know: it will not work to turn a sheet of metal tiles on the roof in different directions. Since each sheet has its own "top" and its own "bottom".

This feature of the metal tile makes it difficult to install roofs of complex broken shape, which have internal and external valleys. As a rule, the implementation of the roof of such structures is associated with a large amount of waste roofing material.

Therefore, it is very difficult to rationally use a metal tile in this case. And there is a need for cutting metal tiles. Many homeowners are very afraid of this.

We are in a hurry to dispel another myth: high-quality cutting of metal tiles with professional tools (specially designed for this) will not bring any harm to the material.

Accordingly, you should not worry about possible corrosion at the cutting points. Moreover, the installation instructions for metal tiles must provide for horizontal alignments in different places: inserting skylights, exiting chimneys and ventilation pipes.

Each horizontal joint must have a lock, which ensures reliable sealing.

Metal tiles of standard dimensions during installation increase the amount of waste - this is another myth. As a rule, the amount of waste directly depends on the quality of the installation.

Joints of the material cannot be avoided.

A word of advice: choose a metal tile sheet length of no more than 4 meters. Longer sheets are very difficult to transport, lift to the roof. Incorrectly performed actions can lead to deformation of the sheets, which will have a very negative effect on the quality of vertical joints on the roofing. Therefore, choosing sheets with a length of 4 meters, even if the length of the slope is longer, you will get only horizontal joints.

In order for the roof to please the owner of the house with its characteristics for many years and fulfill its function of protecting the roof and the entire house by 100%, it is necessary to calculate the size of the roof and roof at the design stage, even before construction begins.

Then you will know exactly such parameters as: metal tile sheet size.

And you will not need to cut the sheets, trying to fit the roof to the existing material. That is, it is best to do the opposite: at the project stage, “fit” the roof to the standard dimensions of the roofing material.

Did the article help you?